Aluminum Tray with Aluminum Pipes

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 sets set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are the largest aluminum profilemanufacture in

Please see more info as belows:

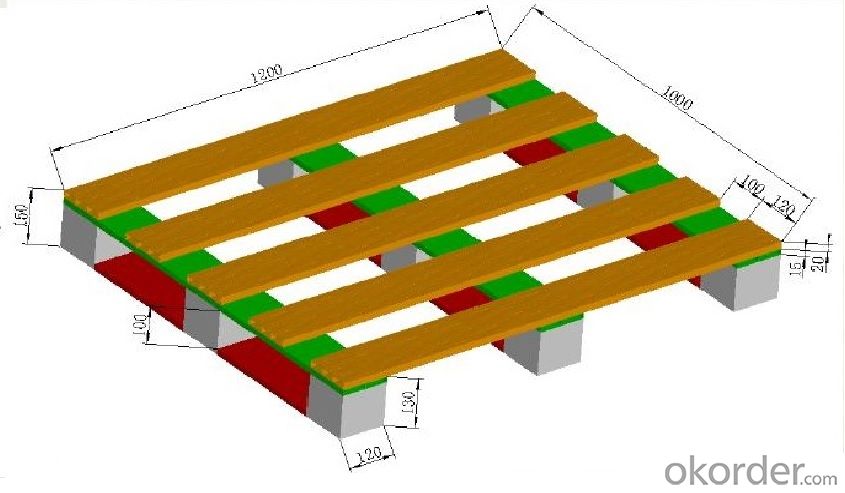

No. | Dimension(mm) | Weight(kg) | Alloy | Dynamic load | Static load | Load mode | Processing type |

1 | 1200×1000×153 | 14.84 | AL6061-T6 | 1.5t | 3t | Single side | Welding |

2 | 1200×1000×150 | 14.38 | AL6061-T6 | 1.5t | 3t | Single side | Welding |

3 | 1200×1000×150 | 21.56 | AL6061-T6 | 1.5t | 3t | Double side | Welding |

4 | 1200×800×150 | 11.90 | AL6061-T6 | 1.5t | 3t | Single side | Welding |

5 | 1200×800×150 | 17.62 | AL6061-T6 | 1.5t | 3t | Double side | Welding |

6 | 1100×1100×150 | 14.39 | AL6061-T6 | 1.5t | 3t | Single side | Welding |

7 | 1100×1100×150 | 20.96 | AL6061-T6 | 1.5t | 3t | Double side | Welding |

8 | 1200×1000×150 | 14.13 | AL6061-T6 | 1.5t | 3t | Single side | Riveting |

9 | 1200×1000×150 | 18.60 | AL6061-T6 | 1.5t | 3t | Double side | Riveting |

- Q: Ask for advice,According to the type of aluminum alloy, Al-Si, Al-Mg, Al-Mg-Si, Al-Mn, Al-Cu, Al-Zn-Mg (T0-T8 heat treatment); if the steel type crystal like austenite, ferrite, Aluminum Alloy have similar crystal like heat treatment, whether similar to the regulation, for advice! Thank you

- For these Aluminum Alloy you said, in fact, we often say that the 4XXX series, 6XXX series, 5XXX series aluminum forging, antirust aluminum, 3XXX series, 2XXX series aluminum, aluminum 7XXX series, 7XXX series I've seen can be tempered (just to stress), other if there is no need to do heat treatment, but the aluminum can generally do hard oxidation hardening, but surface hardening, the hardness is not the core.

- Q: Are aluminum pipes suitable for cryogenic applications?

- Aluminum pipes are not appropriate for cryogenic applications, as they become brittle and lose their mechanical properties at temperatures below -150°C (-238°F). Additionally, aluminum has a low melting point and inadequate thermal conductivity, rendering it unsuitable for use in extremely low temperatures. To guarantee the system's integrity and safety in cryogenic applications, materials such as stainless steel or other alloys with superior low-temperature characteristics are favored.

- Q: How do aluminum pipes perform in extreme weather conditions?

- Aluminum pipes are renowned for their exceptional performance in the most extreme weather conditions. With their inherent properties, such as a high strength-to-weight ratio and resistance to corrosion, aluminum pipes can endure a wide range of weather conditions while maintaining their structural integrity. When faced with extremely cold temperatures, aluminum pipes exhibit remarkable thermal conductivity, enabling them to rapidly dissipate heat and prevent freezing. This quality makes them ideal for applications like refrigeration systems or pipelines in arctic regions, where the preservation of fluid flow is crucial. Conversely, in scorching hot weather, aluminum pipes can withstand thermal expansion, ensuring they remain dimensionally stable and do not distort under high temperatures. This advantage is particularly beneficial in industries such as aerospace, automotive, or HVAC, where aluminum pipes are commonly employed. Additionally, aluminum's high melting point provides further assurance of its performance in extreme heat. Moreover, the corrosion resistance of aluminum is a crucial aspect of its ability to withstand harsh weather conditions. Aluminum naturally forms a protective oxide layer on its surface, preventing rusting and deterioration caused by moisture, humidity, or exposure to acidic or alkaline environments. This characteristic makes aluminum pipes highly suitable for outdoor applications, where they are exposed to rain, snow, or other weather elements. Nevertheless, it is important to acknowledge that severe weather conditions like hurricanes, tornadoes, or severe earthquakes can present challenges for any material, including aluminum pipes. In such cases, it is vital to consider the overall structural design, installation techniques, and additional reinforcements to ensure the pipes perform optimally and last for a long time. In conclusion, aluminum pipes excel in extreme weather conditions. Their impressive thermal conductivity, resistance to thermal expansion, and corrosion resistance make them highly reliable in both cold and hot environments. However, it is crucial to consider the specific application, installation methods, and potential external factors to guarantee optimal performance and safety.

- Q: How do aluminum pipes compare to plastic pipes in terms of durability?

- Aluminum pipes generally offer higher durability compared to plastic pipes. Aluminum is a stronger and more rigid material, making it less prone to cracking, warping, or breaking under pressure or extreme temperatures. Additionally, aluminum pipes have a longer lifespan and are less susceptible to degradation from UV exposure or chemical reactions. However, plastic pipes may be more resistant to corrosion and are often cheaper and easier to install. The choice between aluminum and plastic pipes ultimately depends on the specific application and desired durability requirements.

- Q: Can aluminum pipes be used for wastewater disinfection systems?

- Yes, aluminum pipes can be used for wastewater disinfection systems. Aluminum is a corrosion-resistant material that can withstand the harsh chemicals typically used in disinfection processes. Additionally, aluminum pipes are lightweight, durable, and cost-effective, making them a suitable choice for wastewater treatment applications.

- Q: Are aluminum pipes suitable for pulp and paper processing?

- Yes, aluminum pipes are suitable for pulp and paper processing. Aluminum is a corrosion-resistant material that can withstand the harsh chemicals and conditions commonly found in the pulp and paper industry. It is also lightweight, making it easier to handle and install. Additionally, aluminum pipes offer good thermal conductivity, ensuring efficient heat transfer in various processing applications.

- Q: What are the benefits of an aluminum tube cigar?

- Easy to carry, no need to buy cigars separatelyDon't smoke. You can take it backIt has certain anti-collision function

- Q: What's the material of aluminium pipe 6063?

- As for the chemical composition, according to the national standards are: silicon 0.2-0.6%; iron 0.35%; copper 0.1%; manganese 0.1%; magnesium 0.45-0.9%; chromium 0.1%; zinc 0.1%; titanium 0.1%; the remaining aluminum.

- Q: What is the aluminum soft on the automobile engine? What role does it play?

- To prevent the wear of aluminum tubes, you can see that the aluminum tubes wrapped in cotton are very close to other things

- Q: Can aluminum pipes be used for irrigation controllers?

- Yes, aluminum pipes can be used for irrigation controllers. Aluminum pipes are commonly used in irrigation systems due to their durability, corrosion resistance, and lightweight nature. They are also cost-effective and relatively easy to install and maintain. However, it is important to consider the specific requirements of the irrigation system and consult with professionals to ensure the suitability of aluminum pipes for the specific application.

Send your message to us

Aluminum Tray with Aluminum Pipes

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 sets set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords