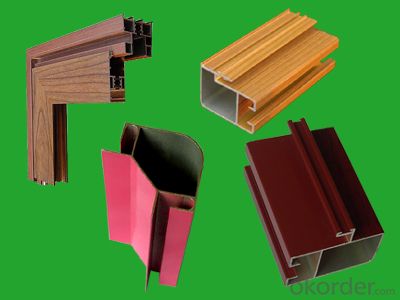

Aluminum Window Door Pipes

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are the largest aluminum profilemanufacture in

Material | Alloy Aluminum 6063,6061,6005,6082 or customer nominated |

Temper | T3, T4, T5, T6 and other |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Not more than 16 meters |

Good Package | Inner plastic film /outside carton/wooden pallets |

Payment Method | T/T, L/C, etc |

Delivery Time | Normally 2-4 weeks, Delivery time can be consulted. |

Press Machine | 500-12500 tons all together 93 press lines. |

Fabrication | 1. Furniture;2. Drilling; 3. Bending; 4. Cutting; 5. Windows and doors;6.etc. |

Certificate | ISO/TS 16949,DNV,IRIS,CCS,AFA,etc. |

Dies | 1. Using our dies, no fee; |

2. Using customer drawing, opening dies, usually about 5~50 tons then the dies cost can be refunded. | |

3. Die cost is negotiable base on the order quantity | |

Capability | Annual output 800,000 tons |

- Q: The same size or different specifications of the square aluminum tube, T how to connect more beautiful ah?!

- According to the precision points: ordinary aluminum tube and precision aluminum tube, in which the precision aluminum tube generally needs to be processed after extrusion, such as cold drawn, fine drawn, rollingBy thickness: ordinary aluminum tube and thin-walled aluminum tubePerformance: corrosion resistance, light weight.

- Q: Ask for advice,According to the type of aluminum alloy, Al-Si, Al-Mg, Al-Mg-Si, Al-Mn, Al-Cu, Al-Zn-Mg (T0-T8 heat treatment); if the steel type crystal like austenite, ferrite, Aluminum Alloy have similar crystal like heat treatment, whether similar to the regulation, for advice! Thank you

- There is no phase change in the process of heating aluminum alloy, so there is no corresponding hard treatment by heat treatment. However, some aluminum parts which are extruded by cold can be softened by heat, but the softening process is more to eliminate the stress without phase change. For these Aluminum Alloy you said, in fact, we often say that the 4XXX series, 6XXX series, 5XXX series aluminum forging, antirust aluminum, 3XXX series, 2XXX series aluminum, aluminum 7XXX series, 7XXX series I've seen can be tempered (just to stress), other if there is no need to do heat treatment, but the aluminum can generally do hard oxidation hardening, but surface hardening, the hardness is not the core.

- Q: Are aluminum pipes suitable for cryogenic applications?

- Aluminum pipes are not appropriate for cryogenic applications, as they become brittle and lose their mechanical properties at temperatures below -150°C (-238°F). Additionally, aluminum has a low melting point and inadequate thermal conductivity, rendering it unsuitable for use in extremely low temperatures. To guarantee the system's integrity and safety in cryogenic applications, materials such as stainless steel or other alloys with superior low-temperature characteristics are favored.

- Q: How do aluminum pipes handle vibration and shock loads?

- Aluminum pipes generally have good resistance to vibration and shock loads due to their inherent strength and stiffness. The lightweight nature of aluminum helps absorb and dampen vibrations, reducing the risk of damage or failure. Additionally, aluminum's excellent fatigue resistance allows it to withstand repeated shock loads without significant degradation in performance. However, the specific ability of aluminum pipes to handle vibration and shock loads may vary based on their design, thickness, and other factors.

- Q: I am now a lot of goods, some can be folded, and some directly broken, and this is how it happened?

- As a rule, T5 can not be bent. If you want to fold it, you need to heat it and then fold it.O or H status can be bent

- Q: Which pressure is high between titanium tube and aluminium tube?

- It depends on how to compare, pure titanium tube or titanium alloy tube? Pure aluminum tube or aluminium alloy tube? Titanium alloys and aluminium alloys are divided into many grades.

- Q: Now a part of the connecting pipe of the air conditioner from the past to pure copper aluminum copper combined pipe, aluminum copper pipe is better seller says. Is it better in the end? Please help me professional fans.

- Surely all copper tubes are better. If using copper aluminum tube, when can not be good?. I have a good reason here only one: if using two kinds of materials of copper aluminum pipe as the performance of the different coefficients of expansion in the summer if installed correctly, it may in the winter there will be gaps to the leakage of refrigerant.

- Q: How to weld air conditioning round aluminum tube

- In general, the first and third types can be welded with WE5 wire, and in second cases Q303 welding. About WE53 and Q303 welding, you can search online WE53 welding operation teaching video, a detailed understanding of the principles and methods of operation

- Q: How can the fridge aluminum pipe trachoma be filled?

- 3., if the tube trachoma too much, you can cut it, re - replace a new tube, welded at both ends.

- Q: The aluminum extrusion seam? Is there a big difference between the two?

- Seamless aluminum tube production process: reverse through the core (hole) to form seamless pipeThe production process of aluminum tube seam: conventional tubes is generally used for combination die extrusion, which is produced by extrusion, is welded, the welding seam is automatically in high temperature.

Send your message to us

Aluminum Window Door Pipes

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords