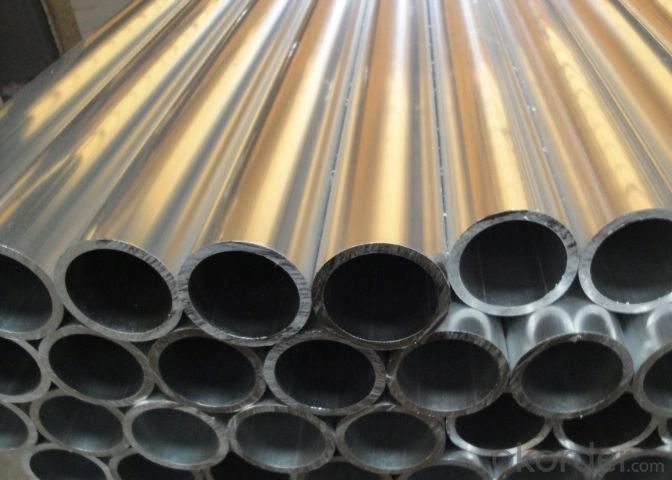

Aluminum Pipes 3005

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Pipe 3005:

1.Specifications of aluminium pipe 3005

1)Alloy:3005;

2)Wall thickness : 0.4mm-80mm ;

3)Outer diameter : 10-900mm ;

4)Length : 6m-9m.

2.Application of aluminium pipe 3005:

aluminum window, door, curtain wall, hand railing, normal aluminum profile, decorative and industrial aluminum profile

3.Features of aluminium pipe 3005:

High weather resistance anti scratch anticorrosion and good weather resistance subtle edges and elegant appearance and easy processing and installation high brightness and hardness.

4.Packaging of aluminium pipe 3005:

protection foam heat contracted plastic film,Wooden packing , Metal pallet

- Q: Are aluminum pipes suitable for HVAC systems?

- Yes, aluminum pipes are suitable for HVAC systems. They are lightweight, corrosion-resistant, and have excellent thermal conductivity, making them ideal for carrying both liquids and gases in HVAC applications. Additionally, aluminum pipes are easy to install, maintain, and have a long lifespan, making them a reliable choice for HVAC systems.

- Q: Ask for advice,According to the type of aluminum alloy, Al-Si, Al-Mg, Al-Mg-Si, Al-Mn, Al-Cu, Al-Zn-Mg (T0-T8 heat treatment); if the steel type crystal like austenite, ferrite, Aluminum Alloy have similar crystal like heat treatment, whether similar to the regulation, for advice! Thank you

- There is no phase change in the process of heating aluminum alloy, so there is no corresponding hard treatment by heat treatment. However, some aluminum parts which are extruded by cold can be softened by heat, but the softening process is more to eliminate the stress without phase change.

- Q: Can aluminum pipes be used for brewery equipment?

- Yes, aluminum pipes can be used for brewery equipment. Aluminum is a commonly used material in the brewing industry due to its various advantageous properties. It is lightweight, corrosion-resistant, and has good thermal conductivity. These characteristics make aluminum pipes suitable for different applications in brewery equipment, such as transferring fluids, connecting various components, or even constructing heat exchangers. However, it is important to consider the specific requirements of the brewing process, such as the type of beer being brewed and the specific application of the pipes, to ensure compatibility and suitability.

- Q: Are aluminum pipes suitable for wastewater treatment facilities?

- Yes, aluminum pipes are suitable for wastewater treatment facilities. Aluminum is a durable and corrosion-resistant material, which makes it a suitable choice for numerous applications, including wastewater treatment. It is particularly useful in environments where the pipes are exposed to chemicals or corrosive substances found in wastewater. Aluminum pipes are lightweight, making them easy to install and handle during maintenance or repair work. Additionally, aluminum has a high strength-to-weight ratio, which means it can withstand high pressure and stress without compromising its structural integrity. Overall, aluminum pipes offer several advantages for wastewater treatment facilities, making them a suitable choice for this application.

- Q: Do aluminum pipes require any special maintenance?

- In general, there is no need for any special maintenance for aluminum pipes. Nevertheless, it is crucial to ensure that they remain free from debris or substances that might lead to corrosion. To maintain the appearance and functionality of the aluminum pipes, it is adequate to clean them regularly using mild soap and water. Furthermore, it is recommended to check for and fix any leaks or damages to guarantee the longevity and efficiency of the piping system. Overall, aluminum pipes are renowned for their durability and rust resistance, making them a low-maintenance choice for diverse applications.

- Q: Can aluminum pipes be used for solar panel installations?

- Yes, aluminum pipes can be used for solar panel installations. Aluminum is a lightweight and durable material that is resistant to corrosion, making it suitable for outdoor applications like solar panel installations. Additionally, aluminum pipes are easy to work with and can be easily customized to meet the specific requirements of solar panel mounting systems.

- Q: Can anodized aluminum 6061-T6 surface be oxidized?

- The so-called T6 is a kind of heat treatment, the main process is rolling solid solution and aging, these steps is to let the inner Aluminum Alloy changed, the metal can reach high strength and long deformation, anodic oxidation of our workpiece can have better conductivity and not the impurity content of workpiece the 6061 is too high, a low impurity content of his aluminum alloy aluminum is much less than, so the conductivity of aluminum has good ductility and high anodic oxidation and chemical polishing, is a good choice.

- Q: Can aluminum pipes be used for wastewater pumping stations?

- Yes, aluminum pipes can be used for wastewater pumping stations. Aluminum pipes are lightweight, corrosion-resistant, and durable, making them suitable for various applications, including wastewater pumping stations. They have excellent resistance to rust and are less likely to corrode compared to other metals, such as iron or steel. Additionally, aluminum pipes have a smooth interior surface, which helps to minimize friction and improve the flow of wastewater. However, it is essential to consider the specific requirements of the wastewater pumping station, including the pressure, flow rate, and chemical composition of the wastewater, to ensure that aluminum pipes are the appropriate choice for the project.

- Q: Are aluminum pipes suitable for vacuum systems?

- Yes, aluminum pipes are suitable for vacuum systems. Aluminum is a commonly used material in vacuum systems due to its excellent strength-to-weight ratio, corrosion resistance, and ability to maintain a vacuum-tight seal. Additionally, aluminum pipes can be easily welded, allowing for seamless connections and minimizing the risk of leaks in vacuum applications.

- Q: Can aluminum pipes be used for electrical conduits?

- Yes, aluminum pipes can be used for electrical conduits. Aluminum is a lightweight and corrosion-resistant material, making it suitable for various applications, including electrical systems. Aluminum conduits are commonly used in industrial and commercial settings due to their durability and cost-effectiveness. However, it is important to note that aluminum is a good conductor of electricity, so proper insulation and grounding are necessary to ensure safety. Additionally, it is advisable to consult local building codes and regulations to ensure compliance with specific requirements for electrical conduit materials.

1. Manufacturer Overview

| Location | Guangdong, China |

| Year Established | 2006 |

| Annual Output Value | Above US$50 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Nanhai Port |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aluminum Pipes 3005

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords