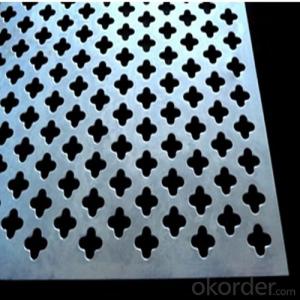

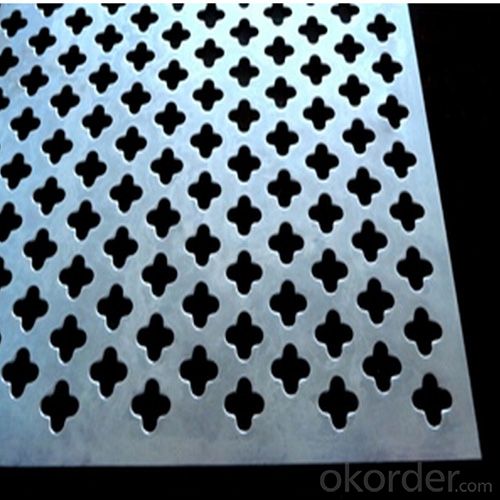

Aluminum Perforated Sheets Thin - Decorative Cloverleaf Pattern

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

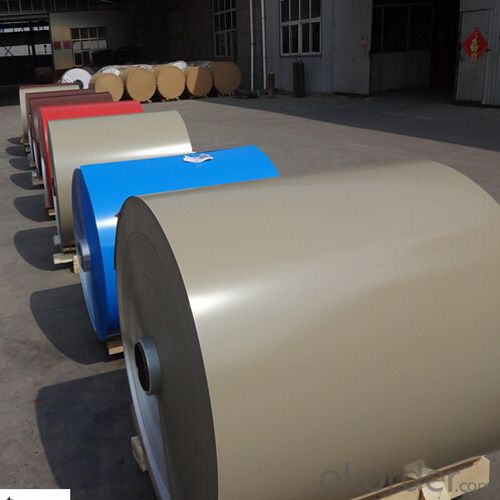

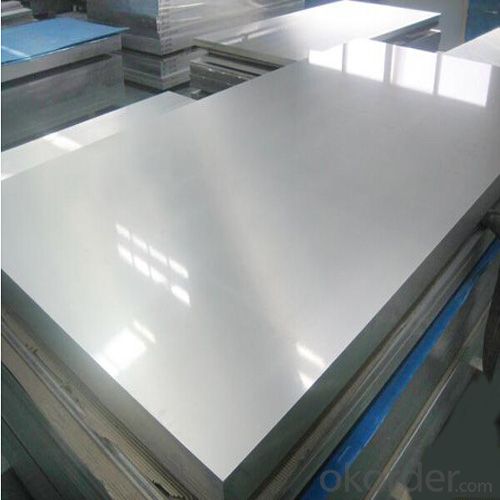

You Might Also Like

Specification

1.Structure of Perforated Metal Decorative Cloverleaf Aluminum Sheet Description:

Perforated Metal Decorative Cloverleaf Aluminum Sheet are widely used for building use, decoration use, making cookware, busing making, shipping building, airplane making and so on。Sizes of aluminum sheet for decoration use: Thickness: 0.3mm~300mm Width: Under 2000mm ( Standard: 1000mm, 1219mm, 1500mm, 1540mm) Length: Under 10000mm. Products commonly used in signs, billboards, building exterior decoration, bus body, high factory wall decoration, kitchen sink, lamp, fan, electronic components, chemical apparatus, sheet processing, deep drawing or spinning hollow ware, welding parts, heat exchangers, Bell surface and plate, plates, kitchen utensils, accessories, safety equipment and other.

2.Main Features of Perforated Metal Decorative Cloverleaf Aluminum Sheet:

Good mechanical properties.

Easy processing, wearability.

Corrosion resistance

Resistance to oxidation.

3. Perforated Metal Decorative Cloverleaf Aluminum Sheet Images:

4. Perforated Metal Decorative Cloverleaf Aluminum Sheet Specification:

| Aluminium sheet | |||||

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| A1050,A1060, A1070,A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

| 3A21,A3003,A3105,A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

| A5052 ,A5005,A5083,A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

| A6061,A6082,A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

| A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

5.FAQ

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process..

- Q: Are aluminum sheets prone to warping?

- Under certain conditions, aluminum sheets may be susceptible to warping. Unlike steel, aluminum is a relatively soft metal, making it more prone to bending or distorting. However, the extent of warping in aluminum sheets depends on various factors, including sheet thickness, alloy composition, temperature exposure, and applied stress levels. Thinner aluminum sheets have less structural integrity, making them more prone to warping. Conversely, thicker sheets are more resistant to warping due to their increased rigidity. The specific alloy composition of the aluminum sheet also affects its susceptibility to warping. Warping can occur due to temperature fluctuations. High temperatures cause aluminum to expand, and without proper support, it may bend or warp. Similarly, rapid cooling causes contraction, leading to warping. The level of stress applied to aluminum sheets can contribute to warping. Excessive bending, pressure, or unevenly distributed loads can deform the sheet. To minimize warping, it is crucial to handle aluminum sheets carefully, provide adequate support during temperature changes, and avoid applying excessive stress. Additionally, using thicker sheets or selecting alloys with higher tensile strength helps reduce the risk of warping.

- Q: Are 101 aluminum sheets suitable for chemical storage tanks?

- No, 101 aluminum sheets are not suitable for chemical storage tanks as they lack the necessary corrosion resistance for handling and storing chemicals.

- Q: How is the thickness of an aluminum sheet measured?

- Various methods can be employed to measure the thickness of an aluminum sheet. One commonly used technique involves the utilization of precision measuring tools like a micrometer or caliper. By placing the micrometer on one end of the sheet and gradually closing it until it reaches the other end, an accurate measurement of the thickness can be obtained. This particular method is suitable for thin aluminum sheets. For thicker sheets, a thickness gauge can be utilized. This gauge consists of a compact handheld device equipped with a probe that is pressed against the surface of the sheet. The gauge then displays the thickness reading on a screen. This approach proves especially advantageous when measuring thicker sheets as a micrometer or caliper may not be feasible. An alternative means of measuring the thickness of an aluminum sheet involves the use of an ultrasonic thickness gauge. This tool emits ultrasonic waves from a transducer, which are subsequently reflected back from the surface of the sheet. By calculating the time taken for the waves to travel and return, the gauge can determine the thickness of the sheet with great accuracy. This method is particularly effective for measuring the thickness of large or irregularly shaped aluminum sheets. To summarize, the thickness of an aluminum sheet can be determined using a variety of tools such as a micrometer, caliper, thickness gauge, or ultrasonic thickness gauge, depending on the thickness and size of the sheet.

- Q: What are the different methods of surface protection for aluminum sheets?

- Some of the different methods of surface protection for aluminum sheets include anodizing, painting, powder coating, and laminating with protective films.

- Q: Is it possible to use aluminum sheets as a material for the exterior walls of high-rise buildings?

- <p>Yes, aluminum sheets can be used for exterior walls in high-rise buildings. They are lightweight, durable, and resistant to corrosion, making them suitable for such applications. Aluminum sheets can also be coated or anodized to provide additional protection and aesthetic appeal. They are often used in combination with other materials or as a cladding system to enhance the building's appearance and energy efficiency.</p>

- Q: Can aluminum sheet be used for electrical enclosures?

- Yes, aluminum sheet can be used for electrical enclosures. Aluminum is a popular choice for electrical enclosures due to its excellent conductivity, lightweight nature, and corrosion resistance. It provides effective shielding against electromagnetic interference and offers good heat dissipation properties. Additionally, aluminum is easily formable, allowing for the creation of complex shapes and designs. Overall, aluminum sheet is a suitable material for electrical enclosures and is commonly used in various industries including electronics, telecommunications, and power distribution.

- Q: Are aluminum sheets suitable for electrical applications?

- Aluminum sheets are appropriate for electrical applications, as they possess numerous advantages. Primarily, aluminum is a highly conductive metal, which has led to its increasing popularity in electrical applications. Furthermore, its lightweight nature and exceptional heat dissipation properties make it an optimal choice for applications that necessitate efficient thermal management. This is particularly critical in electrical systems where heat generation occurs, including power transmission lines, electrical panels, and heat sinks. Moreover, aluminum sheets exhibit high resistance to corrosion. Unlike certain other metals, aluminum forms a protective oxide layer on its surface, preventing further oxidation and corrosion. This makes it a reliable option for electrical applications that are exposed to harsh environments or moisture. Additionally, aluminum is a cost-effective alternative compared to other metals frequently used in electrical applications, such as copper. It is easily obtainable and has a lower price point, making it appealing to both manufacturers and consumers. However, it is important to acknowledge that aluminum has lower electrical conductivity than copper. Consequently, for certain applications where high conductivity is essential, such as power transmission lines, copper may still be preferred. Nonetheless, advancements in technology and design have enabled aluminum to be effectively utilized in a wide range of electrical applications, encompassing wiring, connectors, bus bars, and transformers. In summary, aluminum sheets are indeed suitable for electrical applications, offering advantages like lightweight construction, exceptional thermal management, corrosion resistance, and cost-effectiveness. The ultimate determination of whether to employ aluminum or another material hinges on the specific requirements and limitations of the electrical application in question.

- Q: I would like to use an alloy of copper often called aluminum bronze or aluminum brass for making wire wrapped jewelry but I am unable to find a supplier. An alloy that has no zinc or lead would be best to avoid toxicity problems. This alloy should be principally copper and aluminum but other added materials would be acceptable if not toxic. Nickel, silicon, manganese, and iron are sometimes added to increase performance of the alloy and should be acceptable (no lead or zinc please). The material obviously needs to be bendable enough to work with wire wrapping so if it is brittle it will not work. It should then be at least as usable as aluminum, copper, or stainless steel wire.

- My lady I nonetheless use it to cook dinner my hams and turkeys and to store meals in the frig, however its fitting a dinosaur and its on its last leg and there may be so many different matters now we can use but up to now years it had its use but science and Tech. Has come and made it out of date. However still I like to apply it to ocassions

- Q: Can aluminum sheets be anodized?

- Aluminum sheets are capable of undergoing anodization, which is an electrochemical procedure responsible for generating a safeguarding oxide layer on the aluminum's surface. This particular layer amplifies the metal's resistance against corrosion, its endurance, and its overall appeal. Anodization is widely utilized in various industries, such as automotive, aerospace, and construction, in order to furnish aluminum sheets with a defensive coating and enhance their visual aesthetics. The process entails submerging the aluminum sheet into an acidic electrolyte solution and subsequently passing an electric current through it. As a result, oxygen ions merge with the aluminum atoms and construct the oxide layer. This layer can be further augmented by incorporating dyes or pigments, resulting in diverse colors and finishes. All in all, anodization proves to be an adaptable and efficient technique for treating aluminum sheets.

- Q: How to solve the loose bonding of aluminum sheet and silica gel?

- Bonding silicone rubber needs surface treatment, after using silicone rubber surface treating agent of Kuer , you can bond them with 4211 adhesive.

Send your message to us

Aluminum Perforated Sheets Thin - Decorative Cloverleaf Pattern

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords