Aluminum Oxide Sanding Sheets for Aluminum Sheets AA3004 Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

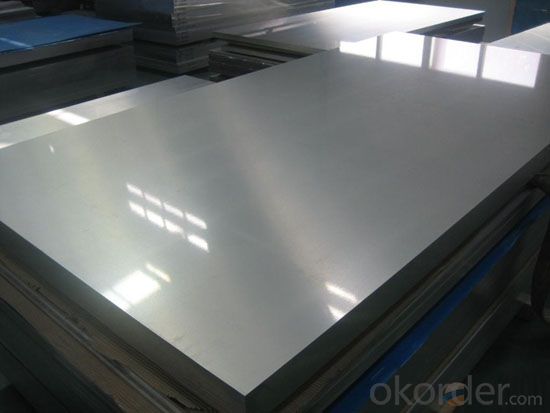

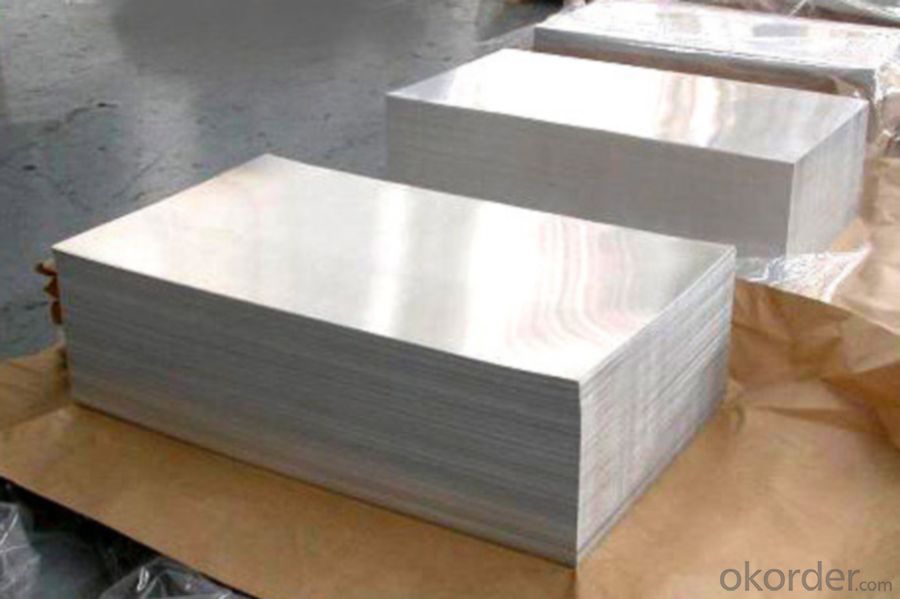

1.Structure of Aluminum Sheets AA3004 Used for Constrcution Description

Aluminum Sheets AA3004 Used for Constrcution has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

Aluminum Sheets AA3004 Used for Constrcution is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of Aluminum Sheets AA3004 Used for Constrcution

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

3.Aluminum Sheets AA3004 Used for Constrcution Images

4.Aluminum Sheets AA3004 Used for Constrcution Specification

Alloy | AA3004 |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of Aluminum Sheets AA3004 Used for Constrcution

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test Aluminum Sheets AA3004 Used for Constrcution.

B.When will you deliver the products?

Aluminum Sheets AA3004 Used for Constrcution will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: Why must the aluminum oxide be electrolyzed in a molten cryolite solution?

- To electrolyse aluminium oxide, it has to be molten. However, the melting point of Al2O3 is extremely high ( 1000°C), and that would make the electrolysis very inefficient. However, Al2O3 dissolves in cryolite at much lower temperatures (lower than 900°C), which makes it a much more viable process.

- Q: Can aluminum sheets be easily formed or bent?

- Yes, aluminum sheets can be easily formed or bent due to their high malleability and low density.

- Q: Do aluminum cans melt in typical campfires? I know the melting point is about 660 Celsius but do campfires get that high? I thought it would just be that the can becomes disfigured and collapses due to the heat, not due to it melting. Even if it did melt in the fire how would you find the remains? The can in a liquid form would certainly not be confined to one part of the fire and therefore wouldn't solidify in a small pool to see if it had melted or not. Any ideas?

- Typical campfires do not get that hot. The can can become disfigured but it wont completely melt.

- Q: Where does China make aluminum plate?

- In many parts of the country have aluminum factory, the old state-owned enterprises have 101, SWA aluminum plant, located in the southwest, northeast china. The emerging aluminum processing base in Henan, due to resource advantages, the largest aluminum factory, the price is relatively low.

- Q: What is the weight of aluminum sheets per square foot?

- The weight of aluminum sheets per square foot can vary depending on the thickness or gauge of the sheet. On average, a 1/8 inch thick aluminum sheet weighs around 1.9 pounds per square foot. However, thinner sheets may weigh less, while thicker sheets can weigh more. It is important to consider the specific thickness of the aluminum sheet when determining its weight per square foot.

- Q: What is the maximum sheet size available for aluminum sheets?

- The maximum sheet size available for aluminum sheets varies depending on the specific supplier and manufacturer. However, commonly available sheet sizes for aluminum range from 4 feet by 8 feet (1219mm x 2438mm) to 5 feet by 10 feet (1524mm x 3048mm).

- Q: I was looking at Audioque subs earlier and what is the difference between copper and aluminum coiled subs. do aluminum last longer or something?

- to maintain it common......Copper is better at removing or soaking up warmth than aluminum yet aluminum is better at dissipating it or doing away with it. i think it is why you spot aluminum CPU coolers with copper cores.

- Q: Are aluminum sheets suitable for pharmaceutical applications?

- Aluminum sheets are well-suited for pharmaceutical use, as they possess a range of advantageous properties. Firstly, their lightweight nature and exceptional resistance to corrosion make them an ideal choice for packaging pharmaceutical products. By shielding the contents from external factors like moisture, light, and oxygen, which could potentially compromise the medication's quality, aluminum sheets offer excellent protection. Additionally, aluminum sheets are highly malleable and can easily be molded into different shapes and sizes, allowing for customized packaging designs. Moreover, their availability in various thicknesses provides options for different types of pharmaceutical products, including tablets, capsules, and liquid medications. Furthermore, aluminum sheets boast a remarkable barrier property that effectively prevents the transfer of odors, flavors, and contaminants. This barrier ensures the integrity and safety of the medication throughout its entire shelf life. Furthermore, aluminum is a non-toxic material, guaranteeing that it does not react with drugs or alter their composition. This quality makes it an optimal choice for pharmaceutical applications, where maintaining the purity and stability of the medication is of utmost importance. In conclusion, aluminum sheets are highly suitable for pharmaceutical applications, thanks to their lightweight nature, corrosion resistance, barrier properties, and non-toxic composition. By efficiently safeguarding and preserving pharmaceutical products, they ensure the quality and safety of these crucial medications.

- Q: i bought a light fixture for my bathroom wall and the ground wire is aluminum and the existing ground wire in the wall is copper,so i would like to know if i can join them and if so,how?

- I assure you that if the light fixture was manufactured in the last 10 years, that ground wire is not aluminum. It may look aluminum but it isn't. aluminum small gauge wire for electricity has been illegal for many years. Why? It will create sparks eventually. --- So you can join that aluminum-looking ground wire to your house ground wire. (Make sure the connection is super tight - in case some nutcake put an aluminum wire for the light fixture ground) If you are still in doubt -- just replace the aluminum-looking ground wire at the fixture and replace it with a copper groung wire) btw: (aluminum is stlll allowed in heavy gauge wires from transformers to service entry panels (if they are greased at the service entry panel)

- Q: What are the different methods of surface texturing aluminum sheets?

- Aluminum sheets can be textured in various ways, each with its own advantages and applications. 1. Mechanical Texturing involves using mechanical tools or processes, like brushing, sanding, or embossing, to create patterns or textures on the surface of aluminum sheets. This method is commonly used to achieve a matte or brushed finish, enhancing the appearance and concealing imperfections. 2. Chemical Texturing involves using chemicals to etch the surface of aluminum sheets and create unique patterns or textures. Acid etching, for example, selectively dissolves the surface to create a textured effect. This method is often employed to improve adhesive properties, making the sheets suitable for bonding or coating applications. 3. Anodizing is an electrochemical process that forms a controlled oxide layer on the surface of aluminum sheets. It can create various textures, ranging from smooth and glossy to rough and matte. Anodizing not only enhances the appearance but also improves corrosion resistance and durability. It is commonly used in architecture, consumer products, and automotive parts. 4. Laser Texturing utilizes laser technology to create precise and intricate patterns or textures on aluminum sheets. Laser beams can be accurately controlled to remove material or modify the surface, allowing for highly customized and detailed textures. This method is often utilized in high-end applications, such as jewelry, signage, or interior design. Each texturing method offers unique benefits and is suitable for different applications. The choice depends on factors such as desired texture, durability requirements, aesthetic preferences, and intended use of the aluminum sheets.

Send your message to us

Aluminum Oxide Sanding Sheets for Aluminum Sheets AA3004 Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords