Aluminum Honeycomb Sheets 6061/6082-T6 for Mould - Aluminum Alloy Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminum Alloy Plate 6061/6082-T6 for Mould Description:

The alloy 6061 has very good welding characteristics and may be welded by all of the common welding techniques. Gas tungsten arc welding is generally used for thin sections and gas metal arc welding is used for heavier sections.Commonly used in the manufacture of heavy-duty structures requiring good corrosion resistance, truck and marine components, railroad cars, furniture, tank fittings, general structural and high pressure applications, wire products, and in pipelines.

2.Main Features of Aluminum Alloy Plate 6061/6082-T6 for Mould:

Good mechanical properties.

Easy processing, wearability.

Corrosion resistance

Resistance to oxidation.

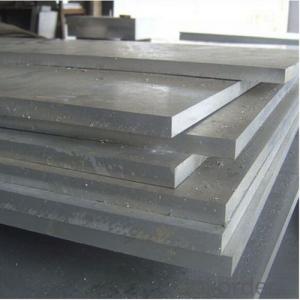

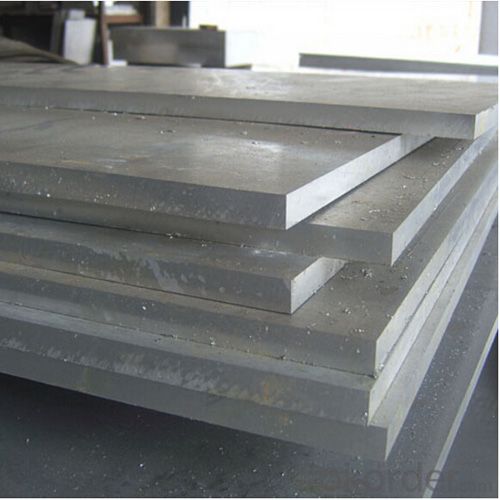

3. Aluminum Alloy Plate 6061/6082-T6 for Mould Images:

4. Aluminum Alloy Plate 6061/6082-T6 for Mould Specification:

| Aluminium sheet | |||||

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| A1050,A1060, A1070,A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

| 3A21,A3003,A3105,A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

| A5052 ,A5005,A5083,A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

| A6061,A6082,A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

| A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: Is it possible to use aluminum sheets as a material for flooring?

- <p>Yes, aluminum sheets can be used for flooring applications. They are known for their durability, resistance to corrosion, and ease of maintenance, making them suitable for various environments. Aluminum flooring is often used in commercial, industrial, and residential settings due to its strength and lightweight nature. It can be found in applications such as walkways, ramps, and as a covering for platforms. However, it's important to note that aluminum may not be the best choice for all flooring needs, especially where thermal insulation or a softer, warmer feel is desired.</p>

- Q: Are aluminum sheets prone to warping?

- Under certain conditions, aluminum sheets may be susceptible to warping. Unlike steel, aluminum is a relatively soft metal, making it more prone to bending or distorting. However, the extent of warping in aluminum sheets depends on various factors, including sheet thickness, alloy composition, temperature exposure, and applied stress levels. Thinner aluminum sheets have less structural integrity, making them more prone to warping. Conversely, thicker sheets are more resistant to warping due to their increased rigidity. The specific alloy composition of the aluminum sheet also affects its susceptibility to warping. Warping can occur due to temperature fluctuations. High temperatures cause aluminum to expand, and without proper support, it may bend or warp. Similarly, rapid cooling causes contraction, leading to warping. The level of stress applied to aluminum sheets can contribute to warping. Excessive bending, pressure, or unevenly distributed loads can deform the sheet. To minimize warping, it is crucial to handle aluminum sheets carefully, provide adequate support during temperature changes, and avoid applying excessive stress. Additionally, using thicker sheets or selecting alloys with higher tensile strength helps reduce the risk of warping.

- Q: How does the aluminum plate manufacturer prevent the aluminum plate from scratching?

- Chaoyang aluminum manufacturers tell you that you can ask the manufacturer to cover the aluminum plate surface, to prevent aluminum plate scraping it!

- Q: I deal with aluminum plate material 2A12, thickness 14mm, crack, same temperature treatment, diameter 8mm aluminum bars, no cracks, original aluminum plate quenching crack, and aluminum plate, the material is closed

- If the material is right may be burned, a full air bubble is parts of the surface, whether the intergranular cracking section, part to do see the metallographic analysis of grain size, lower furnace installed furnace capacity amount control too much away from the direction of the thermocouple parts temperature indicator indicates the temperature to the temperature time lag of thermocouple thermocouple has high temperature parts away from the direction. 510 is enough to regularly test the stove uniformity and precision with 2 kinds of stove fan check

- Q: An aluminum clock pendulum having a period of 1.00 s keeps perfect time at 20 degrees celcius. (A) When placed in a room at a temperature of -5.0 Celcius, will it gain or lose time? (B)How much time will it gain or lose every hour.

- this concerns change in length of aluminum due to fall in temp T(20 C) = 2pi√(L20/g = 1 sec L20 = g/4pi^2 ----------- (1) T(-5 C) = 2pi√(L5/g L5 = T(5)^2*g /4pi^2 ----------- (2) coefficient of linear expansion of aluminum = alpha alpha = delta L/L* delta T 23*10^-6 = (L5 - L20) /L20*(- 5 - 20) (L5 - L20) /L20 = - 25*23*10^-6 L5/L20 = 1 - 25*23*10^-6 = 0.999425 --- (3) L5 decrease in length T(5) will reduce (2) / (1) L5/L20 = [T(5)^2*g /4pi^2] * [4pi^2/g] = 0.999425 [T(5)^2] = 0.999425 T(5) = 0.9997 sec this is period when in (-5 C) room a) pendulum gains time in cold room word gains is used because it takes less in 1 oscillation. b) it gains time = 1 - 0.9997 = 0.0003 sec in 1 sec gain in every hour = 0.0003*3600 = 1.08 sec

- Q: What are the different methods for punching aluminum sheets?

- There are several different methods for punching aluminum sheets, each with its own advantages and applications. Some of the common methods include: 1. Manual Punching: This method involves using hand-operated tools such as handheld punches or hole punches to manually create holes or shapes in the aluminum sheet. It is suitable for small-scale or low-volume production and provides flexibility in terms of hole size and shape. 2. Mechanical Punching: Mechanical punching involves the use of a mechanical press machine equipped with a punch and die set. The sheet is fed into the machine, and the punch is driven through the material, creating holes or shapes. This method is faster and more efficient than manual punching and is suitable for medium to high-volume production. 3. CNC Punching: Computer Numerical Control (CNC) punching utilizes automated machinery that is programmed to punch holes or shapes based on a digital design. The aluminum sheet is loaded onto the machine, and the CNC controls the movement of the punch and die to create precise and complex patterns. CNC punching offers high accuracy, repeatability, and speed, making it ideal for high-volume production and intricate designs. 4. Laser Punching: Laser punching combines the use of a laser cutter and a mechanical punch to create holes or shapes in aluminum sheets. The laser beam vaporizes or melts the material, while the punch pushes the cut part out of the sheet. This method offers high precision, versatility, and the ability to cut complex shapes quickly. However, it is typically more expensive and time-consuming compared to other methods. 5. Notching: Notching is a method used to create V-shaped or U-shaped cuts in aluminum sheets. It is often used for joining or folding the material to form corners or edges. Notching can be done manually or with the help of a mechanical notching machine. The choice of punching method depends on various factors such as the desired hole size and shape, production volume, precision requirements, complexity of design, and budget. It is essential to consider these factors and consult with experts to determine the most suitable method for punching aluminum sheets based on specific needs and applications.

- Q: Characteristics of anodized aluminium plate

- (5) strong pollution resistance: no fingerprints, but also traces of dirt, easy to clean, no corrosion spots.(6) applicability: it is widely used in metal aluminum ceiling, curtain wall, aluminum plate, aluminum plastic panel, fireproof board, honeycomb aluminum plate, aluminum veneer, electrical panel, cabinet panel, furniture panel, etc..

- Q: Its been bugging me for years and i want to know why they say aluminum and not aluminium like it is spelt in the Oxford English dictionary and more importantly the universal periodic table, accepted by all countries, does anyone know why? I would like all opinions on this matter, if possible, thank you

- Because it's written Aluminum on the periodic table.

- Q: Are the aluminum sheets suitable for manufacturing kitchen backsplashes?

- Indeed, kitchen backsplashes can be manufactured using aluminum sheets. Aluminum, being a lightweight and durable material, has commendable resistance against corrosion and heat. Moreover, it is effortlessly cleaned and maintained, making it highly suitable for kitchen usage where splatters and spills are prevalent. The versatility of aluminum sheets allows them to be easily cut and shaped to fit any kitchen size and design, providing ample flexibility in creating personalized backsplashes. Furthermore, aluminum contributes a modern and sleek aesthetic, thus imparting a contemporary touch to the kitchen decor. All in all, opting for aluminum sheets as a manufacturing material for kitchen backsplashes is both practical and stylish.

- Q: A 0.2412 gram sample of aluminum ore was dissolved in a dilute mineral acid. The solution was treated with an excess of sodium oxalate. The resultant aluminum oxalate precipitate was filtered, washed and redissolved in mineral acid, then titrated with 42.12 mL of 0.1098 N KMnO4. Calculate the percent of aluminum in the sample.

- determine which you do catch the Hydrogen gas in a balloon. combination Lye with water in a pitcher bottle (Coke liter bottle is huge). drop in Aluminum foil (do no longer give way) and cap off with a balloon. The balloon will fill with hydrogen. do away with the balloon, pinching the backside keeping the hydrogen; shop including Aluminum foil strips and place the balloon lower back over the precise till at last the balloon is of a sturdy length. Tie the balloon off, tape a fuse (some thing that burns slow) to the balloon, permit it bypass up interior the air. whilst the hearth its the balloon, it pops and the hydrogen + oxygen (interior the air) + spark reasons a small flash (hydrogen explosion). Do it at night for a extra advantageous view.

Send your message to us

Aluminum Honeycomb Sheets 6061/6082-T6 for Mould - Aluminum Alloy Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords