Aluminum Foil Facing Mylar Bubble Heat Seal Composite Film

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 32 inch

- Supply Capability:

- 123 inch/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Aluminum Foil Facing Description:

Aluminium foil laminated with PET film

PET laminated aluminum foil is an improved surfacing material for SBS/APP modified bitumen waterproofing membrane.

PET laminated aluminum foil is an improved surfacing material for SBS/APP modified bitumen waterproofing membrane. It has all the aluminum foil functions. Since it is the lamination of PET/PE film and aluminum foil, it is more flexible and with higher strength.

Technical Data

PROPERTIES | TYPICAL DATA |

COMBINED THICKNESS | 35--40 MICRON |

PET FILM:12MICRON ALUMINUM FOIL:10MICRON PET FILM:12 MICRON | |

UNITE WEIGHT | 60-70 G/M2 |

WIDTH | 1020 MM |

SURFACE FINISH | TOP: PET FILM MIDDEL: ALUMINUM FOIL BOTTOM: PET FILM |

TENSILE STRENGTH | LONGITUDINAL> 40 N/15MM TRANSVERSAL> 50 N/15MM |

ELONGATION AT BREAK | LONGITUDINAL>10 TRANSVERSAL>15 |

I.D. | 75-80MM |

O.D.OF ROLL | 450-550MM |

SD VALUE | 7000M(APPROX) |

WATER VAPOUR PERMEABILITY | <0.02 G/M2 D |

COMPOUND CHARACTERISTICS | THE COMPOUND DOES NOT CHANGE ITS CHARACERISTICS WHEN USED AT 180 °C IN A SHORT BITUMEN CYCLE |

2.Main Features of the Aluminum foil facing:

• Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• environmentally friendly,no smell and not-toxic;

• Smooth and clear surface;

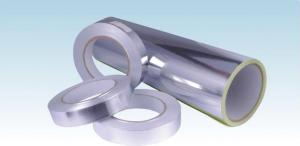

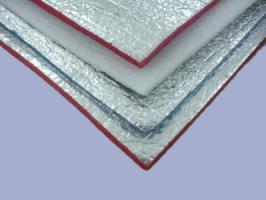

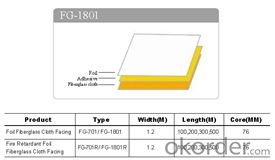

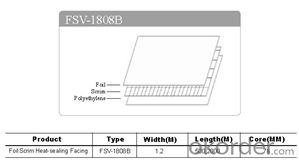

3.Aluminum Foil Facing Images

4.Aluminum Foil Facing Specification

TYPICAL PHYSICAL PROPERTIES:

PROPERTIES | UNIT | VALUE | TEST METHOD | |||||

Basic weight | gsm | 120 | ASTM D646 | |||||

Tensile strength: M. D. X. D. | N/25mm | 180 90 | ASTM C1136 | |||||

Burst strength | N | 50 | ASTM D774 | |||||

Reflectivity of foil surface | % | 95 | ---------- | |||||

Temp. Resistance | -29°C +66°C | No change keep soft | ASTM C1263 | |||||

Water vapor permeance | ng/N.s | 5.75 | ASTM E-96 | |||||

Water Soak Test | 24hrs | No delamination | ---------- | |||||

Width: 1.0 m, 1.2m, 1.25m, 1.3m

Length: 60m,100m,120m, 200m

Core I.D.: 3"(76mm ±1)

Based on order, special sizes are also available.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1. How about your company?

A world class manufacturer & supplier of aluminum foil facing and is one of the large-scale professional investment aluminum foil facing bases in China. Annually more than 1000 containers of aluminum foil facing are exported to markets in Europe, America and Japan.

1. What is the storage condition?

1,The products should be stored at room temperature and kept from wet and heat source.

2, It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

3, The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: This question asks for the proper method of using aluminum foil to wrap food, with emphasis on the correct side of the foil facing outward.

- <p>To wrap food correctly with aluminum foil, you should use the dull side of the foil facing outward, which is in contact with the food. The shiny side has a non-stick surface and is not recommended for direct food contact as it may contain substances that could potentially leach into the food when heated. Start by cutting a piece of foil large enough to fully cover the food. Place the food in the center, then fold the foil over, crimping the edges to seal tightly. This will help retain moisture and heat, and prevent any potential cross-contamination.</p>

- Q: What are the options available to replace aluminum foil when covering food?

- <p>Yes, there are several alternatives to aluminum foil for covering food. Silicone food covers are reusable, heat-resistant, and can be easily washed. Beeswax wraps are an eco-friendly option, made from natural materials and can be used multiple times. Parchment paper is a disposable option that's ideal for baking and can be used in place of foil. Reusable glass or ceramic lids can be used for dishes that need to be covered while cooking. Lastly, some people opt for reusable metal mesh covers, which are suitable for grilling and baking. Each alternative has its own benefits and is chosen based on the specific needs and preferences of the user.</p>

- Q: Can aluminum foil be utilized as a substitute for a frying pan to cook fried rice or stir fry dishes?

- <p>Using aluminum foil to make fried rice or stir fry dishes is not recommended. Aluminum foil is not designed for direct contact with high heat and can melt, leading to uneven cooking and potentially releasing harmful substances into the food. Instead, use a proper non-stick pan or wok designed for high-heat cooking to ensure even heating and prevent food from sticking, which is essential for quick and easy stir frying.</p>

- Q: What safety measures should be considered when using aluminum foil in a kitchen setting?

- <p>When using aluminum foil in the kitchen, it's important to handle it carefully to avoid cuts from sharp edges. Always use a cutting board when cutting foil to prevent damage to countertops. Avoid using aluminum foil with non-stick cookware, as it can scratch the surface. Do not use aluminum foil in broilers or ovens above 450掳F (232掳C), as it can melt and release toxic fumes. Never use aluminum foil to wrap foods that will be cooked in a microwave, as it can cause sparks and fires. Always ensure that foil is properly secured when used to cover food to prevent it from coming into contact with the heating elements of the oven.</p>

- Q: Is it possible to create a pie crust using aluminum foil as a substitute for traditional pie crust materials?

- <p>No, you cannot use aluminum foil to make a pie crust. A pie crust is traditionally made from flour, butter, and water, which when combined and baked, create a flaky, edible crust. Aluminum foil is a metal material not meant for consumption and lacks the properties needed to form a pie crust. It does not have the ability to be rolled out, shaped, or baked into a flaky, edible form. Instead, it's used for wrapping food to retain moisture or for cooking on a grill.</p>

- Q: Is it safe to use recycled aluminum foil for cooking or baking purposes?

- <p>Recycled aluminum foil facing is not recommended for cooking or baking. While aluminum foil itself is safe for cooking and can be used to cover dishes or line baking sheets, recycled foil may have impurities or contaminants from previous uses. It may also be thinner and less durable, leading to potential tearing or puncturing, which can result in food contamination. For safety and food quality, it's best to use new, high-quality aluminum foil for cooking and baking.</p>

- Q: Is it possible to use aluminum foil with a reflective side to line a cake tin for baking purposes?

- <p>Yes, you can use aluminum foil facing to line a cake tin before baking. It helps in creating a smooth finish on the cake and can prevent sticking. However, ensure the foil is food-grade and does not have any sharp edges that could tear or puncture the cake. It's also important to grease the foil lightly to facilitate easy removal of the cake after baking.</p>

- Q: Is it possible to use aluminum foil with a non-stick coating as a substitute for non-stick baking or grilling pans?

- <p>Yes, aluminum foil facing can be used as a non-stick surface for baking pans or grilling pans. It provides a smooth, non-stick surface that prevents food from sticking and makes cleanup easier. However, it's important to ensure that the foil is heavy-duty and not too thin to avoid tearing during use. Additionally, while it can be a temporary solution, it's not as durable as a true non-stick surface and may require frequent replacement.</p>

- Q: Can aluminum foil be used as a material for crafting a pot holder or pot lid holder?

- <p>While aluminum foil is heat resistant to a certain extent, it is not recommended for making a pot holder or pot lid holder due to its low melting point and potential to conduct heat, which could lead to burns or damage to the foil. Instead, consider materials designed for heat resistance such as silicone, fabric with heat-resistant properties, or insulated materials specifically made for kitchen use. These materials are safer and more effective for handling hot pots and lids.</p>

- Q: What are the negative effects on the environment when aluminum foil facing is utilized?

- <p>The environmental impacts of using aluminum foil facing include increased waste generation due to its non-biodegradable nature, leading to landfill accumulation. Aluminum production is energy-intensive, contributing to greenhouse gas emissions. Additionally, improper disposal can lead to water and soil contamination. Recycling rates for aluminum are high, but not all foil is recyclable, and the process itself consumes energy. Overall, aluminum foil facing can have significant environmental consequences if not managed responsibly.</p>

Send your message to us

Aluminum Foil Facing Mylar Bubble Heat Seal Composite Film

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 32 inch

- Supply Capability:

- 123 inch/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords