Aluminum Foil Facing Mylar for Bubble Heat Seal Composite Film and Fire-Retardant PVC

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg/m³

- Supply Capability:

- 500000 kg/m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Aluminum Foil Facing Description:

The production technologies and products performance of aluminum foil facing have been up to international advanced level. The aluminum foil facing products are mainly used for HVAC system, refrigerators, building thermal aluminum foil facing insulation and laminated with glass wool and rock wool to increase the insulation function.

• FSK aluminum foil facing is mainly used for duct wrap in HVAC system and other fields, such as vapor barrier etc., and suitable for off-line lamination of glass wool or rock wool. By special processing, the facing will have excellent flame retardant property.

• Heat-sealing aluminum foil facing is used for duct wrap without applying extra adhesive and suitable for online lamination of glass wool and rock wool.

• The WPSK aluminum foil facing, whose structure is white polypropylene/ fiberglass scrim/ kraft is mainly used for metal building insulation and suitable for the insulation of ware-house, factory, supermarket, office and so on.

2.Main Features of the Aluminum foil facing:

• Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

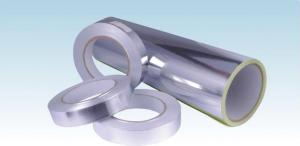

3.Aluminum Foil Facing Images

4.Aluminum Foil Facing Specification

TYPICAL PHYSICAL PROPERTIES:

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 80 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 95 50 | ASTM C1136 |

Burst strength | N | 25 | ASTM D774 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -29°C +66°C | No change keep soft | ASTM C1263 |

Water vapor permeance | ng/N.s | 1.15 | ASTM E-96 |

Water Soak Test | 24hrs | No delamination | ---------- |

Width: 1.0m, 1.2m, 1.25 m, 1.30, 1.37m

Length: 200m, 500m, 1000m, 2500m, 2750m, 3300m

Core I.D.: 3"(76mm ±1), 72mm ±1

Based on order, special sizes are also available.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

(1) How about your company?

A world class manufacturer & supplier of aluminum foil facing and is one of the large-scale professional investment aluminum foil facing bases in China. Annually more than 1000 containers of aluminum foil facing are exported to markets in Europe, America and Japan.

- Q: How safe is your slice of graphite?

- Mainly used in electronic products, photoelectric materials, LCD LCD screen, LCD backlight, portable computer, high gloss plastic board, ordinary plastic board, all kinds of plastic sheets,

- Q: How to remove the layer of protective film on wooden door?

- There are many ways: 1. If the film is not too big, you can apply some lacquer thinner to it and then scrub it with cleaning ball. 2. Detergent used in textile industry will work (Bottled such detergent is called al). I've tried it. It really works well. 3. Use sulfuric acid. But you should mix it with water before use, otherwise the door will corrode. Immerge the door into the mixed sulfuric acid for a period of time and scrub it with cleaning ball. 4. Firstly, use electric hair drier to blow the film. And them slowly tear it off or scratch it off with wooden shovel. The glue marks can be cleaned by solvent oil.

- Q: I didn't tear off the protective film on the air conditioning. Not long ago, I tore it off and found the glue of the film remained. And it's difficult to remove.

- You can give essential balm a try.

- Q: What is the viscous unit of a protective membrane? What is its physical meaning?

- Usually expressed in g/25mm or N/25mmG/25mm=0.01N/25mmFor example, the peel strength of a protective film is 40g/25mm,

- Q: How do I remove the protective film from my suitcase?

- Blow it off with a blower and then remove it slowly.A suitcase is a kind of suitcase. The utility model comprises a luggage case, a telescopic pull rod and a luggage bottom wheel, and is widely used because of the convenient use.The suitcase has a long history. From the only wooden cases, big suitcases, and portable suitcase and trolley boxes of different shapes, the suitcase in people's hands is evolving.

- Q: Does protective film for laptop keyboard affect heat dissipation?

- I suggest you'd better not use keyboard protective film because it will impede the heat dissipation of the computer. If you don't like your keyboard being dirty, you can use blush to clean it (usually included in laptop cleaning kit). And keeping it clean at other times.

- Q: What to do when the keyboard protective film is not adhesive any more?

- 2; 3: Solution: 1. Get a basin of clean water. 2. Gently rub and wash the keyboard protective film in the water without using any detergent. 3. Put it somewhere shady, cool and ventilative (avoid direct sunlight) to dry off. And when it's done, it's adhesive again.

- Q: Does anyone know of a glue that sprays up to form a protective film?

- Adhesive type: cross linking resin adhesiveGlue main component: polyacrylic acid fat;Rosin resinPhysical form: colorless transparent liquid (rosin resin is milky white liquid)Viscosity type: Micro stick, low viscosity, medium viscosity, high viscosity, super high viscosity five seriesUsage: at high temperature with PET, POPP, kraft paper and other materials on the surface of adhesion (coating)Solid content: 40 + 2%

- Q: Is there protective film on the front side of tempered glass film?

- Generally speaking, tempered glass film is put in a small bag to prevent dust, scratches and knocks. The front side of it is a layer of tempered glass. Thus there's no need to coat it with other protective films.

- Q: How to solve the degumming problem of PET protective membrane?

- From our practical experience, basically, we adopt the above methods. Today to share this experience with you, I hope you have a better understanding of the screen protection film.

Send your message to us

Aluminum Foil Facing Mylar for Bubble Heat Seal Composite Film and Fire-Retardant PVC

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg/m³

- Supply Capability:

- 500000 kg/m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords