Aluminum Foil Facing Mylar for Bubble Heat Seal Composite Film

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 kg/m³

- Supply Capability:

- 500000 kg/m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Aluminum Foil Facing Description:

The production technologies and products performance of aluminum foil facing have been up to international advanced level. The aluminum foil facing products are mainly used for HVAC system, refrigerators, building thermal aluminum foil facing insulation and laminated with glass wool and rock wool to increase the insulation function.

• FSK aluminum foil facing is mainly used for duct wrap in HVAC system and other fields, such as vapor barrier etc., and suitable for off-line lamination of glass wool or rock wool. By special processing, the facing will have excellent flame retardant property.

• Heat-sealing aluminum foil facing is used for duct wrap without applying extra adhesive and suitable for online lamination of glass wool and rock wool.

• The WPSK aluminum foil facing, whose structure is white polypropylene/ fiberglass scrim/ kraft is mainly used for metal building insulation and suitable for the insulation of ware-house, factory, supermarket, office and so on.

• Double sided aluminum foil facing vapor barrier, whose structure is aluminum foil/ high strength kraft /fiberglass scrim /aluminum foil and laminated together by special flame retardant adhesive, can be used for roofing, wall insulation of house, warehouse, cold storages, factory and others.

2.Main Features of the Aluminum foil facing:

• Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• environmentally friendly,no smell and not-toxic;

• Smooth and clear surface;

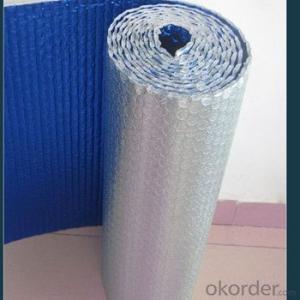

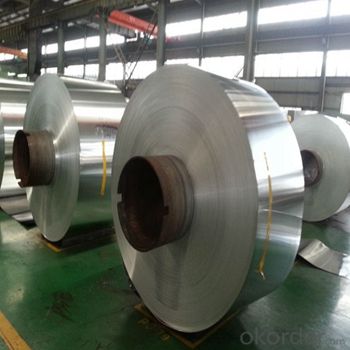

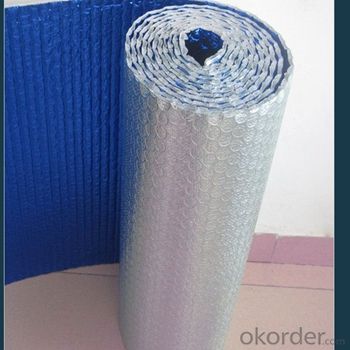

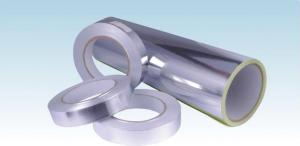

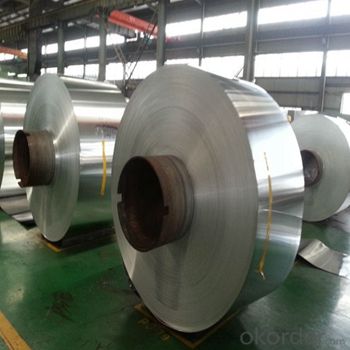

3.Aluminum Foil Facing Images

4.Aluminum Foil Facing Specification

TYPICAL PHYSICAL PROPERTIES:

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 80 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 95 50 | ASTM C1136 |

Burst strength | N | 25 | ASTM D774 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -29°C +66°C | No change keep soft | ASTM C1263 |

Water vapor permeance | ng/N.s | 1.15 | ASTM E-96 |

Water Soak Test | 24hrs | No delamination | ---------- |

Width: 1.0m, 1.2m, 1.25 m, 1.30, 1.37m

Length: 200m, 500m, 1000m, 2500m, 2750m, 3300m

Core I.D.: 3"(76mm ±1), 72mm ±1

Based on order, special sizes are also available.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

(1) How about your company?

A world class manufacturer & supplier of aluminum foil facing and is one of the large-scale professional investment aluminum foil facing bases in China. Annually more than 1000 containers of aluminum foil facing are exported to markets in Europe, America and Japan.

(2)What is the storage condition?

The products should be stored at room temperature and kept from wet and heat source.

It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

- Q: When decorating, enter the door to protect the film, with what glue paste? Usually use sealing tape, a lot of time paste is not smooth, seriously affecting the appearance and image of the company. But the glue needs to be cleaned easily after the decoration is finished! Seek advanced or expert pointing!

- 4, after the completion of the project to remove the protective film, if there is glue mark affixed, the use of alcohol or special cleaning agent to remove glue marks.Door handle1, when the door handle door protection for the aperture, and a transparent tape will handle below the door stickers fixed firmly, the standard of protective film cut into 50 mm wide strips, door handle wound protection, transparent adhesive tape fixed firmly in use can not fall off.2, interior doors installed after the door handle wrapped with plastic wrap and complete sellotaped firm.Standard for finished product protection of windows1, the company unified production of posters posted out word in the middle position around the window, the posters along the 500 mm away from the window sill, no window from the ground 1000 mm.2. Use standard protective film to protect all indoor window fixing fans. The sign is outwards and the sign or word on the protective film is kept flat and vertical. The protective film is laid flat and firm.

- Q: How to remove the protective film on stainless steel elevator?

- Blow the film with electric hair dryer at first. And then carefully tear it off.

- Q: What is the difference between protective film and sticker?

- The original protective film can only protect the screen from scratches and pollutions for the period of time from delivery to use. It's not for regular protection for screen. And it won't work any more after using for a period of time. But sticker is different. Generally, sticker cover the whole product(generally, surface) to prevent dust and scratches. It has wear resistance and somewhat water proofness and quake proofness. But it also has disadvantages. There's a kind of specific glue on the it which makes it difficult to remove the sticker because some glue may remain on the surface of the products.

- Q: How to distinguish the adhesion degrees of Protective film materials?

- It depends on what exact kind of product the customer want. Certain product has certain function and degree of adhesion. 1N or less refers to low degree of adhesion; 1-3N refers to medium degree, and 3N or more, high degree. In addition, there are also slight degree and super degree somewhere.

- Q: Is the laptop monitor covered with protective film?

- We know that the LCD protective film factory configuration is a layer of plastic film, and the film, not only greatly affect the visual effects, reduce the permeability and have a lot of reflection, will affect the user's eye. In addition, the heat dissipation of the display is extremely unfavorable. The plastic film is not a good conductor of heat. The liquid crystal panel will heat up after a period of time, and touch the panel with the back of the hand. You can tell that the temperature is very high. If the surface is coated with a protective film with poor thermal conductivity, it virtually prevents the cooling of the liquid crystal and even shortens the effective life of the display.

- Q: Bought last year's cabinet, outside the layer of protective film for a long time, can not tear down, how to do?

- Hello, I was doing the whole cabinet, this should be torn off, you should be a UV paint, or molded plate, if the tear is molded is no problem, if it is paint it, you can choose a relatively small door with nails off a little bit, it would not take off paint, if not even though you expose, and if you are Aluminum Alloy edge it is best to use the wallpaper knife along the variable scratch Aluminum Alloy, and then open it,Of course, if paint it will expose, when holding the cuticle! You try!

- Q: Excuse me, what reason is mobile phone protection film stuck to mobile phone screen protect film to be able to bubble?

- There are two kinds of foaming reasons, one is in the air, there are two dust wipe clean, this is all right, the first time I posted OK8 film too, thought is broken, fortunately have posted against the instruction above, teach me how to do, okay, squeezed out is, do not use nail squeeze film will bad ~ Cabu out a card package,

- Q: How to remove the protective film of stainless steel?

- There are many ways. 1. If the film is not too big, you can apply some banana oil to it and then scrub it with cleaning ball. 2. Detergent used in textile industry will work (Bottled such detergent is called al). I've tried it. It really works well. 3. Use sulfuric acid. But you should mix it with water before use, otherwise the door will corrode. Immerge the door into the mixed sulfuric acid for a period of time and scrub it with cleaning ball.

- Q: I've never been a salesman. My company wants me to do business, but I don't know how to start doing it. I just got into the company soon. I don't know about the film yet. I don't know where to start.

- Then you start with phone sales, and look for protective coatings on the Internet. Call, ask, sample, try, and then visit.In short, the business is not accomplished overnight, the long-term accumulation of experience, experience in communication with people, product experience, industry experience.

- Q: Stainless steel plastic film for more than a year, how to remove clean? There is also a layer of plastic film after tearing off how to remove?

- The newly bought stainless steel pots or glass stick on some labels, off the labels, stickers on the traces of it is difficult to remove, wipe with a damp cloth, scraping knife will often leave traces, after repeated practice, I summarized some tips to share with you.On the hard surface of the self-adhesive mark, we can use non greasy wash water on the surface of the object, and then gently wipe with soft cloth; with industrial alcohol or gasoline can also remove these traces. If these stickers are found on the skin, they can also be removed with lemon juice.

Send your message to us

Aluminum Foil Facing Mylar for Bubble Heat Seal Composite Film

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 kg/m³

- Supply Capability:

- 500000 kg/m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords