Aluminum Foil Facing Mylar for Bubble Heat Seal Composite Film and All kinds of Fire-Retardant PVC

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg/m³

- Supply Capability:

- 500000 kg/m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Aluminum Foil Facing Description:

The production technologies and products performance of aluminum foil facing have been up to international advanced level. The aluminum foil facing products are mainly used for HVAC system, refrigerators, building thermal aluminum foil facing insulation and laminated with glass wool and rock wool to increase the insulation function.

• FSK aluminum foil facing is mainly used for duct wrap in HVAC system and other fields, such as vapor barrier etc., and suitable for off-line lamination of glass wool or rock wool. By special processing, the facing will have excellent flame retardant property.

• Heat-sealing aluminum foil facing is used for duct wrap without applying extra adhesive and suitable for online lamination of glass wool and rock wool.

• The WPSK aluminum foil facing, whose structure is white polypropylene/ fiberglass scrim/ kraft is mainly used for metal building insulation and suitable for the insulation of ware-house, factory, supermarket, office and so on.

2.Main Features of the Aluminum foil facing:

• Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

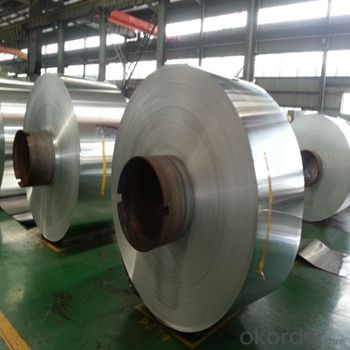

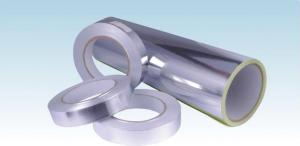

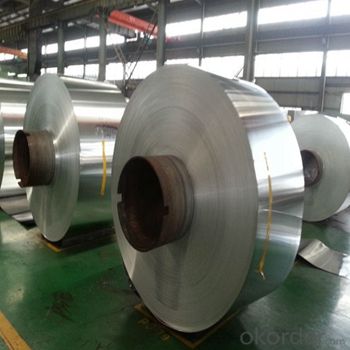

3.Aluminum Foil Facing Images

4.Aluminum Foil Facing Specification

TYPICAL PHYSICAL PROPERTIES:

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 80 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 95 50 | ASTM C1136 |

Burst strength | N | 25 | ASTM D774 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -29°C +66°C | No change keep soft | ASTM C1263 |

Water vapor permeance | ng/N.s | 1.15 | ASTM E-96 |

Water Soak Test | 24hrs | No delamination | ---------- |

Width: 1.0m, 1.2m, 1.25 m, 1.30, 1.37m

Length: 200m, 500m, 1000m, 2500m, 2750m, 3300m

Core I.D.: 3"(76mm ±1), 72mm ±1

Based on order, special sizes are also available.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

(1) How about your company?

A world class manufacturer & supplier of aluminum foil facing and is one of the large-scale professional investment aluminum foil facing bases in China. Annually more than 1000 containers of aluminum foil facing are exported to markets in Europe, America and Japan.

- Q: How to tear off the aging protective film on the security door?

- Blow the film with electric hair drier.

- Q: How do I remove the protective film from my suitcase?

- Blow it off with a blower and then remove it slowly.A suitcase is a kind of suitcase. The utility model comprises a luggage case, a telescopic pull rod and a luggage bottom wheel, and is widely used because of the convenient use.The suitcase has a long history. From the only wooden cases, big suitcases, and portable suitcase and trolley boxes of different shapes, the suitcase in people's hands is evolving.

- Q: What is PVC material protective film?

- PVC material protective film, as its name suggests, is PVC protective film.

- Q: How to prevent the protective film from damage and the stainless steel from marks when drawing the steel?

- The surface quality of drawing dies of stainless steel is highly required. Rough surface can decrease friction and increase the property of adhesive resistance. Therefore, after the grinding processing, the more important work is to remove the processing marks left on the drawing dies. However, few people know the importance of the grinding and polishing processes when making dies. Throughout the whole process, the proportion of grinding and polishing processes should reach one third because the appearance quality of stainless steel products,to a large extent, is determined by the grinding and polishing techniques of making dies. The rougher the surface of dies is, the less it needs re-grinding. And the life of the dies also extends accordingly. If the surface of dies is not well grinded and polished, the marks on the drawn products will be clear. Although there's something to do with the fact that drawing stainless steel can easily cause seizing tumour, too. And to polish these marks takes time and the result is not good. Thus we should pay more attention to the grinding and polishing processes. Only when the surface processing precision of dies improves, can the marks decrease and the life of dies extend. In recent years, various new polishing techniques and polishing tools have arised at home. New processes and equipments such as ultrasonic polishing, electropolishing, abrasive jet and extrusion honing have been developed.

- Q: What is Blu ray? What is the principle of the anti blue protective film?

- Anti blue cell phone film is a vision protection film developed for blue light radiation. Blue light cell phone uses blue ray blocking technology to absorb and transform blue light, so that the blue light can be effectively blocked, and the purpose of protecting eyesight can be achieved.

- Q: What does the pl mean in Protective film pl - 1255 - s pl?

- Pl is the name of manufacturer. Its meaning is similar to KM film.

- Q: How to remove th protective film on the aluminium alloy door which is installed for too long?

- Washing it with hot water and then scratching it off with a small shovel.

- Q: Do you know if there is a computer screen that can be seen only from the front?

- Yes, the computer city can buy, not expensive, more than 20 yuan.

- Q: What are the differences between PE protective film, PET protective film and PVC protective film?

- PE refers to polyethylene. It's commonly used in protective films, featuring low price, softness, excellent ductility and environmental friendliness. Generally speaking, products made from this kind of material must pass the ROHS environmental pollution tests stipulated by European Union. Its disadvantage is poor whether resistance. It's not suitable to be used at temperature more than 60℃. PVC refers to polyvinyl chloride. Its features are good softness and whether resistance. And its disadvantage is non-environmental-friendly. Thus many big international brands rarely use this kind of material. Products made from this kind of material are mainly used for anti-static protection or as the surface of wooden stereo. PET refers to polyester. Its major property is good whether resistance which makes it resistant to high temperature of 100℃ to 150℃, hardness and flatness. And its disadvantage is that it can't be used on angular products.It's mainly used in die cutting.

- Q: Use of protective films,A lot of products can be posted ah,

- The biggest advantage of protective film:The protected products are free from pollution, corrosion and scratches during the process of production, processing, transportation, storage and use, and protect the original bright and clean surface so as to improve the quality of the products and the market competitiveness.

Send your message to us

Aluminum Foil Facing Mylar for Bubble Heat Seal Composite Film and All kinds of Fire-Retardant PVC

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg/m³

- Supply Capability:

- 500000 kg/m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords