Aluminum Foil Facing Bubble Foil Composite Film 7mic Al + 12mic PET

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 53 inch

- Supply Capability:

- 35 inch/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Aluminum Foil Facing Description:

The production technologies and products performance of aluminum foil facing have been up to international advanced level. The aluminum foil facing products are mainly used for HVAC system, refrigerators, building thermal aluminum foil facing insulation and laminated with glass wool and rock wool to increase the insulation function.

• FSK aluminum foil facing is mainly used for duct wrap in HVAC system and other fields, such as vapor barrier etc., and suitable for off-line lamination of glass wool or rock wool. By special processing, the facing will have excellent flame retardant property.

• Heat-sealing aluminum foil facing is used for duct wrap without applying extra adhesive and suitable for online lamination of glass wool and rock wool.

• The WPSK aluminum foil facing, whose structure is white polypropylene/ fiberglass scrim/ kraft is mainly used for metal building insulation and suitable for the insulation of ware-house, factory, supermarket, office and so on.

• Double sided aluminum foil facing vapor barrier, whose structure is aluminum foil/ high strength kraft /fiberglass scrim /aluminum foil and laminated together by special flame retardant adhesive, can be used for roofing, wall insulation of house, warehouse, cold storages, factory and others.

2.Main Features of the Aluminum foil facing:

• Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• environmentally friendly,no smell and not-toxic;

• Smooth and clear surface;

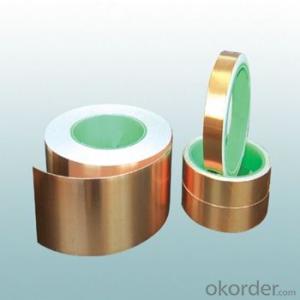

3.Aluminum Foil Facing Images

4.Aluminum Foil Facing Specification

TYPICAL PHYSICAL PROPERTIES:

Name:AL+LDPE | |||

Structure | Thickness(mic) | Weight(g/m2) | Yield(m2/kg) |

AL7+ LDPE12 | 21mic | 36 | |

AL7+ LDPE15 | 24 mic | 39 | |

AL9+ LDPE12 | 23mic | 43 | 23 |

AL9 +LDPE15 | 26mic | 48 | 21 |

AL9 +LDPE19 | 30mic | 54 | 19 |

AL9 +LDPE23 | 34mic | 60 | 17 |

AL12 +LDPE12 | 26mic | 52 | 19 |

AL12 +LDPE15 | 29mic | 56 | 18 |

AL12 +LDPE19 | 33mic | 62 | 16 |

AL12 +LDPE23 | 37mic | 67 | 15 |

AL12 +LDPE36 | 50mic | 87 | 12 |

AL15 +LDPE19 | 36mic | 70 | 14 |

AL25 +LDPE12 | 39mic | 87 | 12 |

AL25 +LDPE23 | 50mic | 102 | 10 |

AL40 +LDPE12 | 54mic | 127 | 8 |

AL40 +LDPE15 | 57mic | 131 | 8 |

AL40 +LDPE23 | 65mic | 143 | 7 |

AL40 +LDPE36 | 78mic | 161 | 6 |

AL50 +LDPE12 | 64mic | 154 | 6 |

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 80 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 95 50 | ASTM C1136 |

Burst strength | N | 25 | ASTM D774 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -29°C +66°C | No change keep soft | ASTM C1263 |

Water vapor permeance | ng/N.s | 1.15 | ASTM E-96 |

Water Soak Test | 24hrs | No delamination | ---------- |

Width: 1.0m, 1.2m, 1.25 m, 1.30, 1.37m

Length: 200m, 500m, 1000m, 2500m, 2750m, 3300m

Core I.D.: 3"(76mm ±1), 72mm ±1

Based on order, special sizes are also available.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

(1) How about your company?

A world class manufacturer & supplier of aluminum foil facing and is one of the large-scale professional investment aluminum foil facing bases in China. Annually more than 1000 containers of aluminum foil facing are exported to markets in Europe, America and Japan.

(2)What is the storage condition?

The products should be stored at room temperature and kept from wet and heat source.

It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

(3) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

(4) How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served

- Q: Is it possible to use aluminum foil with a reflective side to wrap sandwiches?

- <p>Yes, you can use aluminum foil facing to make sandwiches. The reflective side of aluminum foil is food-safe and can be used to wrap sandwiches for storage or transportation. It helps to keep the sandwich fresh and prevents it from drying out. However, it's important to ensure the foil is clean and free from any sharp edges that might tear the bread or packaging. Additionally, it's best to avoid using foil with non-stick coatings on the inside when in contact with food.</p>

- Q: The user is asking if they can repurpose their old aluminum foil facing to create a new pot holder or tea cozy.

- <p>Yes, you can repurpose your old aluminum foil facing to make a new pot holder or tea cozy. Aluminum foil is a good insulator and can be easily cut and shaped to fit your needs. Simply cut the foil to the desired size, fold or wrap it around the pot or tea cozy, and secure it with a rubber band or string. For a more decorative touch, you can cover the foil with fabric or use colorful foil. Always ensure that the aluminum foil does not come into direct contact with the heat source to avoid any potential fire hazards.</p>

- Q: What safety measures should be considered when using aluminum foil in a kitchen setting?

- <p>When using aluminum foil in the kitchen, it's important to handle it carefully to avoid cuts from sharp edges. Always use a cutting board when cutting foil to prevent damage to countertops. Avoid using aluminum foil with non-stick cookware, as it can scratch the surface. Do not use aluminum foil in broilers or ovens above 450掳F (232掳C), as it can melt and release toxic fumes. Never use aluminum foil to wrap foods that will be cooked in a microwave, as it can cause sparks and fires. Always ensure that foil is properly secured when used to cover food to prevent it from coming into contact with the heating elements of the oven.</p>

- Q: This question asks for methods to clean aluminum foil after it has been used for cooking and has old food stuck to it.

- <p>To remove old food from aluminum foil facing after cooking, start by letting the foil cool down to avoid burns. Then, use a plastic scraper or the edge of a credit card to gently scrape off the food particles. For stubborn residue, you can soak the foil in warm, soapy water for a few minutes before scrubbing with a soft sponge or cloth. Avoid using metal scrubbers as they can scratch the foil. After cleaning, rinse thoroughly and dry before storing or reusing.</p>

- Q: Is it possible to use aluminum foil as a cooking utensil for stir-frying or sauteing food?

- <p>While aluminum foil can be used in some cooking applications, it is not recommended for stir-frying or sauteing due to its low melting point and potential for tearing. Aluminum foil can melt at high temperatures, which are often used in stir-frying and sauteing, leading to a fire hazard or uneven cooking. Additionally, the foil may tear or puncture easily, releasing aluminum particles into the food, which is not safe. Instead, use proper cookware like non-stick pans or stainless steel for these cooking methods.</p>

- Q: What are the materials and elements that make up the aluminum foil facing?

- <p>Aluminum foil facing is primarily composed of aluminum, which is a lightweight, malleable, and ductile metal with the symbol Al and atomic number 13. It is commonly used in construction, packaging, and cooking due to its excellent thermal and electrical conductivity, as well as its resistance to corrosion. The aluminum used for foil is typically of high purity, but it may also contain trace amounts of other elements to enhance certain properties, such as copper to improve strength or magnesium to increase resistance to corrosion. The facing can also have a protective layer or coating to prevent oxidation or to enhance its performance in specific applications.</p>

- Q: This question asks for methods to clean stubborn food residue from the aluminum foil facing of a baking sheet or similar kitchen item.

- <p>To remove stuck-on food from aluminum foil facing, first let the surface cool down. Then, use a plastic scraper or an old credit card to gently lift the residue without scratching the foil. For stubborn stains, make a paste of baking soda and water, apply it to the area, and let it sit for a few minutes before scrubbing. Alternatively, use a mixture of vinegar and water to loosen the food particles. After cleaning, rinse thoroughly and dry to prevent further food adhesion.</p>

- Q: Is it possible to use aluminum foil as a baking surface? If yes, what kinds of foods are suitable for baking with aluminum foil?

- <p>Yes, aluminum foil can be used for baking. It's particularly useful for foods that require even heat distribution or need to be shielded from direct heat, such as delicate pastries, fish, or vegetables. It can also be used to prevent food from sticking to the baking sheet or to catch any drips, making cleanup easier. However, it's important to note that some foods, especially those with a high sugar content, can burn if they come into direct contact with the foil, so it's best to use it with a light layer of oil or parchment paper underneath.</p>

- Q: Is it safe to use aluminum foil with a reflective side for food storage?

- <p>Yes, aluminum foil facing can be used for storing food. It is commonly used to wrap, cover, or store food in the refrigerator or freezer to keep it fresh. The aluminum foil creates a barrier that helps to retain moisture and prevent freezer burn. It also protects food from odors and can be used for cooking or reheating in the oven. However, it's important to ensure that the foil does not come into direct contact with acidic or high-sugar foods, as this can lead to a reaction that may cause the aluminum to leach into the food.</p>

- Q: Is it possible to use aluminum foil with a shiny side facing up as a liner for a baking pan?

- <p>Yes, you can use aluminum foil facing as a baking pan liner. The shiny side of the aluminum foil is non-stick and can be used to line baking pans, making it easier to remove baked goods without sticking. Ensure the foil is heavy-duty to withstand high temperatures and prevent tearing. However, avoid using it for direct contact with acidic or alkaline foods, as the foil may react with them. Always follow the manufacturer's guidelines for safe use.</p>

Send your message to us

Aluminum Foil Facing Bubble Foil Composite Film 7mic Al + 12mic PET

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 53 inch

- Supply Capability:

- 35 inch/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords