Roofing Insulation Fasteners - Aluminum Foil EPE/XPE Foam Insulation

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Name of the products

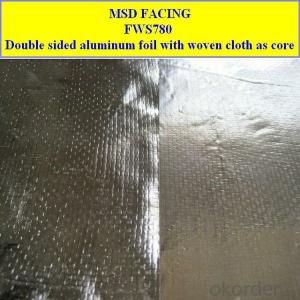

Aluminum foil/XPE,EPE foam insulation

Characteristics

1.light weight,clean,thin,good flexibility and cushioning;

2.invariable if it is attacked repeatedly;

3.It overcomes the shortcoming of general foam such as,rubber ordinary brittle,the distortion,resilient.And also having super waterproof, moisture-proof, quakeproof, sound-insulated,the heat preservation,good plasticity,strong toughness, the circulation restoration, the environmental protection,strong anti-hit strength.So is it one good substitute material for the general packing material.

Application:

It using many flexibility for handbags luggage lining, industrial production of sound insulation,thermal insulation material of agricultural, aquaculture floating equipment, protective sports pad, water rescue operation equipment, home, hotel floor decoration, cushions and so on. The pipe is used extensively for air-conditioning, baby stroller, children's toys, furniture and other industries. EPE laminated fabricit ,as a good decoration material,generally use to various vehicles and living room.EPE alu film and alu foil or other composite products have excellent anti-ultraviolet infrared capabilities.It is also one good substitute material for a number of chemical and camping equipment, cold storage equipment,car shade.

Such as for industrial sheds,commercial buildings,home insulation,under wood or laminated flooring,roof insulation, carpet underlay and construction,packaging material to the sensitive products. To protect precise machine,elevator,slap up furniture ,sun shade,sand beach mat,heat preservation,and terrestrial heat.

| Name of the products | Aluminum foil with FR grade EPE/XPE foam insulation |

| Mainly materials | Aluminum foil,EPE,XPE,IXPE foam,Metallized PET,LDPE,HDPE WOVEN,Air bubble |

| Structure | 1.Alu(Metallized PET)+PE+XPE/EPE 2.Alu(Metallized PET)+PE+XPE/EPE+PE 3.Alu(Metallized PET)+PE+XPE/EPE+PE+Alu(Metallized PET) 4.Alu(Metallized PET)+PE+Woven+PE+XPE/EPE+Woven+PE+Alu(Metallized PET) 5.Alu(Metallized PET)+PE+XPE/EPE+PE Bubble+Alu(Metallized PET) 6.Alu(Metallized PET)+PE+Woven+PE+XPE/EPE+PE Bubble+PE+Woven+PE+Alu(Metallized PET) 7.Customized |

| Aluminum foil thickness | 6.5mic,7mic,9mic,12mic,15mic and so on |

| Metallized PET | 10mic,12mic,15mic and so on |

| Foam thickness | 0.5-7mm |

| Width and length | Width from 0.8-1.6m,length can be 20m,30m,40m,50m,100m and customized |

| Foam color | Red,green,blue,white,black and customized |

Type:Al/4mm EPE/Al

Structure | Al/4mm EPE foam/Al |

Roll Dimension | 1.2m*40m |

Thickness | 4mm |

Weight | 195g/m2 |

Emittance | 0.03 |

Reflectivity | 97% |

R-Value | Up to R-11 |

Flame spread | 25 |

Water Vapour Transmission | 0.012g/m2 Kpa |

Fungi Growth | No Fungi |

Corrosion | Doesn't generate |

- Q: the best way to thermal insulate and water proofing of rcc slabs economical, may be some poly urethane material or whatever but should be very effective and light weight.

- use a polythene sheet . i dont know about where u live but where i live we get very long and broad size thick polythene sheets to make shelter or the protect from rain . even poor ppl use it to make slums . they attach a sheet in bamboo and they bury half of that bamboo stick inside the ground and by arranging 4 of them like this in a square area they make a bamboo frame. then as i said they attach sheet and make temporary home but they live there for years.

- Q: please help..

- probably not a good idea. are you asking about insulation (pink stuff) if so, then it not good with moisture. if you are asking about tar paper on the roof then it would leave tar smell in your car.

- Q: My new room is an addition to a mobile home, and has a single-layer metal roof. I have 3 "main" concerns. What are the cheapest and/or most effective ways of eliminating them?1. No heat insulation- cold air sinks from the roof to my room, and my warm air rises to the roof and cools.2. Condensation forms on the inside and drips occasionally. My computer, bike, and downhill boards are in here!3. It seems like bugs could easily get into my room, but that's just a suspicion.

- welcome to the wonderful world of cheap, temporary roofing. you've just described a metal roof perfectly. bob, tell em what he's won! a lifetime supply of more bad decisions! also, the ugliest roof in town! but best of all, everyone who drives by his home will know he's a bandwagon kind of guy, he doesn't educate himself and do what's wise, he does what everyone else is doing! can't wait till that crowd finds that cliff they've been lookin for!!!

- Q: Can you put fiberglass insulation on the under side of roof tiles in the loft in the house?

- You should not be able to see your roof tiles from inside your house. So no, it can not be done. You can attach insulation to the rafters if that is what you meant.

- Q: Have a patio with metal roof, gets very hot during summer. Will Great Stuff insulate and stick to hot roof during summer? Thanks

- I don't think Great Stuff foam insulation is meant to be applied in the manner in which you need. It is used to fill gaps and cracks, not be sprayed out in thin coats. whenever I've used it in the past, I found out it did not like to be spread out, or "worked".

- Q: I know when you inhale the insulation from the roof irritates the throat but what can you do to clear it from your throat after inhaling it?

- it's not your throat you should be worried about. it's your lungs. wear a respirator....or at the very least, a dust mask. you only live once so make it last.

- Q: i have about 200 sq ft of odd shaped polystyrene foam (rigid) insulation between 3" and 5" thick. it's leftover from installing a flat roof on a commercial building. creative ideas anyone? grind it and use it as attic insulation in a home?thanks.

- I'm a bit confused here Andy. If the flat roof needs replacing, when it is removed what is revealed is going to be exactly what you would see if you removed the ceilings. So why consider removing the ceilings if they are ok? When the flat roof is replaced put the insulation in then. Whilst rockwool would have been the material to use there is now roofing insulation board that is much more efficient, 50mm board gives equivalent insulation of something like 150mm rockwool. If the flatroof isn't fitted with suitable vents to keep it ventilated fit them when the roof is done too. The only reason I can see for replacing the ceiling plasterboard is if it hasn't got a vapor barrier ie foil backed board.

- Q: If I insulate my roof, should I put in those plastic vents that go between the studs for air flow? I would like to use it for a work shop and probibly have some kind of heat source. i live in Northern Alberta.....

- Rabbits do not choose supplemental warmth whilst in a development. Rabbits are lots greater beneficial appropriate to handle chilly climate than they are to handle warm climate. warmth lamps won't purely reason a hearth probability, they'll purely approximately insure that the animals gets pneumonia. make beneficial they have extremely some nutrition, a BOWL of heat water three times an afternoon (do not use water bottles in the iciness), and field complete of hay/straw to burrow into, and that they would be high quality.

- Q: I added a screened room to my mobile home. I also have vinyl windows. in the summer the sun beats down on the home almost all day Someone told me I could have insulation installed in the roof panels, and that i may even be able to do it myself. Right now it's impossible to enjoy my patio between 1-5pm because it so hot you can't breath. I'm in the Pasco, FL area - 34667Appreciate any help you can give

- Mobile home refoofing, I had it done, and they did it in one day. They came and installed 2inch foiled insulation right over the existing roof. Then they installed new roof panels..Unbeliveable how much cooler in the summer and warmer in the winter. It will pay for itself living up here in the Northeast..

- Q: I have a vented metal roof. WV winters

- Check into heat tape tied to pipe, with insulation wrapped around that. turns on when freezing temperatures. insulation by itself, will not stop it from freezing if left for long periods without water moving through it. .

Send your message to us

Roofing Insulation Fasteners - Aluminum Foil EPE/XPE Foam Insulation

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords