Ray St Clair Roofing Insulation - Aluminum Foil Composite Material for Thermal Insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Foil Bubble Heat Insulation

Description of Aluminum Foil Bubble:

Aluminum foil and bubble is the better product in the environmental protection, thermal insulation thermal insulation. The outermost PET has good abrasion resistance and high strength tear resistance. The bubble between the aluminum foil not only has a strong moisture, resistance oxygen, sound insulation, drop noise function, aluminum foil bubble also has very good reflective inverse heat, blocking ultraviolet.

Features of Aluminum Foil Bubble:

It is the high quality heat insulating and the invincible opponent of anti- condensation. The low and stable coefficient of heat conduction has good isolation effect.

The product has many advantages, such as light weight, heat insulation, shock absorption, sound absorption and noise reduction;

The product is easy to install and process and it also waterproof, seepage control, flame retardant.

The product also has many features, such as heat resistance, low temperature resistance, chemical resistance, ageing resistance etc.

Application of Aluminum Foil Bubble:

Building reflective heat, cold and hot water pipe insulation;

Refrigerator partition, central air conditioning, refrigerator and household appliances insulation;

Insulation, sound-absorbing, noise reduction and moisture-proof insulation in the car, train, refrigerator car, laboratory and other industries;

Special product packaging and refrigerated packing and so on.

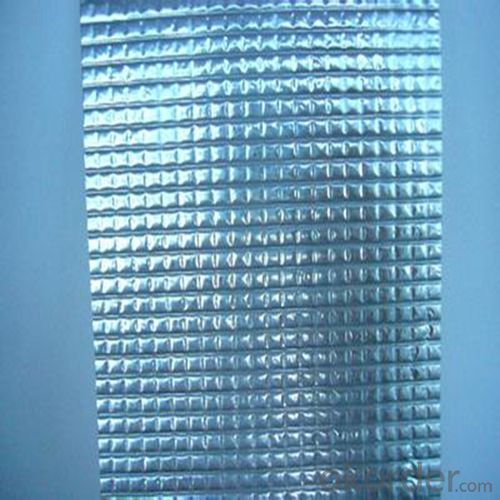

Pictures of Aluminum Foil Bubble

Specification of Aluminum Foil Bubble

STRUCTURE | ALUMINUM FOIL/BUBBLE/ALUMINUM FOIL | ALUMINUM FOIL/ BUBBLE/BUBBLE/ALUMINUM FOIL | ALUMINUM FOIL/WOVEN CLOTH/BUBBLE/WOVEN CLOTH/ALUMINUM FOIL | MPET /BUBBLE/MPET | ALUMINUM FOIL/BUBBLE/FOAM/BUBBLE/ALUMINUM FOIL |

THICKNESS | 1-4mm | 8mm | 6.5mm | 4mm | 4mm |

WEIGHT | 120GSM | 240GSM | 180GSM | 120GSM | 445GSM |

BUBBLE SIZE | 4mm HIGH x 10mm DIAMETER | 2mm HIGH x 10mm DIAMETER | 4mm HIGH x 20mm DIAMETER | 4mm HIGH x 10mm DIAMETER | 2mm HIGH x 10mm DIAMETER FOAM THICKNESS: 3.5MM |

WIDTH | 1.2m (MAX 1.5m) | 1.2m (MAX 1.5m) | 1.2m (MAX 1.5m) | 1.2m (MAX 1.5m) | 1.2m (MAX 1.5m) |

THERMAL CONDUCTIVITY | 0.034w/mo | 0.032 w/mo | 0.032w/mo | 0.034w/mo | 5.87m2.k/w |

REFLECTIVITY | 96-97% | 96-97% | 96-97% | 96-97% | 96-97% |

FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of aluminum foil bubble insulation,is one of the large-scale professional investment aluminum foil composite insulation bases in China, consisting of both casting foundry forging and machining factory. Annually more than 100,000 square meters foil insulation are exported to markets in Europe, America and Japan. OEM service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 20 to 25 working days can be served.

④What is the storage condition?

The welded wire mesh should be stored at room temperature and kept from wet and heat source.

- Q: do I have to blow insulation in the roof of my mobile home if I install foam insulation under a meatle roof?

- Some mobiles have a vented attic and some don't. If your attic is vented, the foam on the roof won't help insulate inside the house. I've blown insulation into a mobile home attic before (vented attic), but some mobiles one can't (not vented attic). There are different variations of attic venting, dictating if you can blow in or not. I would add insulation anyway, if you can, mobiles usually skimp on attic insulation, even if they are "certified".

- Q: the roof of my mouth hurts bad.i worked all day with sawdust and insulation yesterday.is this the problem.?

- it is what might have irritated your mouth. use a mask in the future. for now, increase your fluid intake and try Benedryl for a few days.

- Q: Live in Houston, very hot and humid. Looking at adding radiant and additional insulation to roof in house. We have a lot of sun, and AC bills.

- we live in the desert, and got our roof coated, and instantly noticed the difference, it is much more insulated, and provides protection against leak (which was the main reason we had it done)

- Q: I am really confused about this science stuff! Sustainability is terrible xP

- All versions of insulation are largely air that is kept from moving - air is a good insulator if convection - movement of heated or cooled air due to changes of density - is prevented. This assumes that a vapor barrier and caulking prevent actual air movement through the wall when a wind is blowing. Some insulators are also poor conductors of heat so the connection between inside and outside that might occur is broken. As it happens, glass used in fiberglass and minerals used in rock wool are actually pretty good conductors of heat in solid form but as fine particles and flakes they don't conduct well from one strand/piece to the next.

- Q: I would like to find foam type tiles for my roof of decking, insulation?

- www.okorder I checked the website I posted by searching 'foam roofing' on google. This link is what I found but there are others... Google it to find your best deal. I think I will spray this stuff under my pier and beam home just to insulate. Thanks for the tip! I can buy this product, apply it myself and cut the cost down to 1/3 or more.

- Q: House is a bi-level. Recently added storm windows to deck off dining room. Having a new rubber roof installed would like to know if we can insulate ceiling to make the room warmer. What product do you suggest we use. we are getting conflicting answers, some say you can insulate others say the ceiling needs to breath having a rubber roof install. Please advise.

- Your other answerer is correct. The little plastic pieces that he speaks of are sometimes called baffles. They look like they are corregated or wavy like the inside of cardboard. These are essential to letting air flow in the attic space. Another item that you must have are vents on the soffits or overhangs on either side of the roof. Air has to get in there somehow. There are alot of homes that are not ventilated properly and the roof decking or plywood gets discolored and rots from the inside out. Sometimes this can happen in as little as 5 years, depending on your geographical location. Rubber roofing is usually put on a flat roof system. If you do not have access to inside the framing, you cannot insulate or it will be very difficult to get insulation in there properly. There are so many variables with different houses and locations. You may want to ask an insulation expert from the phone book or even a home inspector. Good luck.

- Q: i have about 200 sq ft of odd shaped polystyrene foam (rigid) insulation between 3" and 5" thick. it's leftover from installing a flat roof on a commercial building. creative ideas anyone? grind it and use it as attic insulation in a home?thanks.

- I'm a bit confused here Andy. If the flat roof needs replacing, when it is removed what is revealed is going to be exactly what you would see if you removed the ceilings. So why consider removing the ceilings if they are ok? When the flat roof is replaced put the insulation in then. Whilst rockwool would have been the material to use there is now roofing insulation board that is much more efficient, 50mm board gives equivalent insulation of something like 150mm rockwool. If the flatroof isn't fitted with suitable vents to keep it ventilated fit them when the roof is done too. The only reason I can see for replacing the ceiling plasterboard is if it hasn't got a vapor barrier ie foil backed board.

- Q: What can i do to add more insulation in a addition in my house?The Roof is flat on this addition (no attic room for insulation there).Looks like it's only 4 or 5 inches thick, starts from the inside with 1/2 inch drywall and the rest is plywood, and then that black sheeting on the outside.IS THERE ANYTHING MORE THAT CAN BE DONE TO ADD MORE INSULATION ON THE OUTSIDE?, (i can't do anything on the inside since the ceiling is already low) SINCE IN THIS ROOM IS VERY HOT, even touching the celing feels warm, PLEASE HELP!

- You could have foam roofing installed over the existing roof covering. Look up "foam roofing" on the Internet.

- Q: I have a vented metal roof. WV winters

- Check into heat tape tied to pipe, with insulation wrapped around that. turns on when freezing temperatures. insulation by itself, will not stop it from freezing if left for long periods without water moving through it. .

- Q: What are the roof insulation materials?

- Is made from volatile polystyrene beads containing volatile liquid foaming agent, and a white solid having a fine closed-cell structure which is thermoformed in a mold after being preheated by heating

Send your message to us

Ray St Clair Roofing Insulation - Aluminum Foil Composite Material for Thermal Insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords