Gaf Tapered Roofing Insulation Aluminum Foil with LDPE Heat Seal for Bubble Foil Facing Production

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 90 cm²

- Supply Capability:

- 33412 cm²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

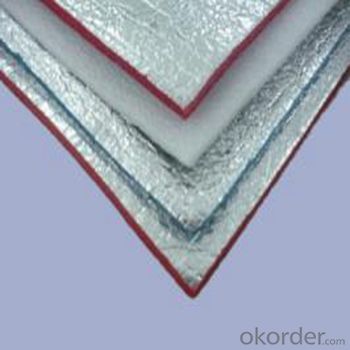

Aluminum foil facing insulation for Roofing Insulation

1. Aluminum Foil Facing Description:

The production technologies and products performance of aluminum foil facing have been up to international advanced level. The aluminum foil facing products are mainly used for HVAC system, refrigerators, building thermal aluminum foil facing insulation and laminated with glass wool and rock wool to increase the insulation function.

• Heat-sealing aluminum foil facing is used for duct wrap without applying extra adhesive and suitable for online lamination of glass wool and rock wool.

• The PSK aluminum foil facing, whose structure is white polypropylene/ fiberglass scrim/ kraft is mainly used for metal building insulation and suitable for the insulation of ware-house, factory, supermarket, office and so on.

• Double sided aluminum foil facing vapor barrier, whose structure is aluminum foil/ high strength kraft /fiberglass scrim /aluminum foil and laminated together by special flame retardant adhesive, can be used for roofing, wall insulation of house, warehouse, cold storages, factory and others.

2.Main Features of the Aluminum foil facing:

• Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• environmentally friendly,no smell and not-toxic;

• Smooth and clear surface;

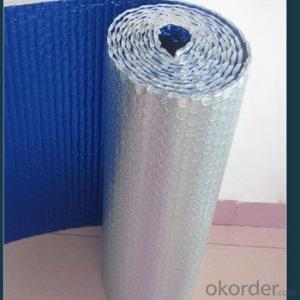

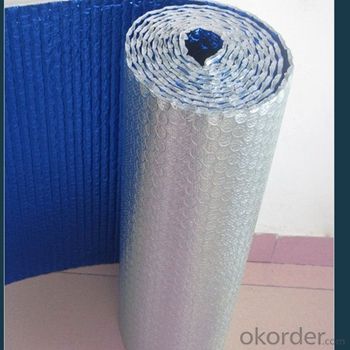

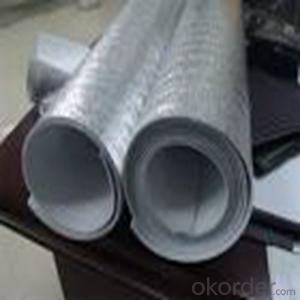

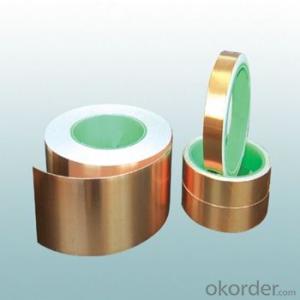

3.Aluminum Foil Facing Images

4.Aluminum Foil Facing Specification

TYPICAL PHYSICAL PROPERTIES:

Basic weight | gsm | 120 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 140 75 | ASTM D828 |

Burst strength | N | 43 | ASTM D774 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -29°C 66°C | No Delamination No Delamination | ASTM C1263 |

Water vapor permeance | ng/N.s | 1.15 | ASTM E-96 |

Basic weight | gsm | 120 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 140 75 | ASTM D828 |

Width: 1.0m, 1.2m, 1.25 m, 1.30, 1.37m

Length: 200m, 500m, 1000m, 2500m, 2750m, 3300m

Core I.D.: 3"(76mm ±1), 72mm ±1

Based on order, special sizes are also available.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1. How about your company?

A world class manufacturer & supplier of aluminum foil facing and is one of the large-scale professional investment aluminum foil facing bases in China. Annually more than 1000 containers of aluminum foil facing are exported to markets in Europe, America and Japan.

What is the storage condition?

1,The products should be stored at room temperature and kept from wet and heat source.

2, It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

3, The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: hi me and my friends made a lounge out of my old tin roof shed we have a tv speakers and a few other electrical goods... since winters on its way we were wondering whats the best and cheapest way to insulate the place note that its a tin rof but has wood under it where the old indulation used to be the place is pretty chilly and sometime damp plz help we dont wanna be freezing our asses off in there thanks :)

- I'm assuming that it's open at the ceiling.You could put in a drop ceiling to hold the heat further down.If it's damp you may want to make sure the area between the ceiling an roof are well ventilated.You could then place insulation on top of your drop ceiling so there's a barrier to hold down heat.

- Q: Live in Houston, very hot and humid. Looking at adding radiant and additional insulation to roof in house. We have a lot of sun, and AC bills.

- we live in the desert, and got our roof coated, and instantly noticed the difference, it is much more insulated, and provides protection against leak (which was the main reason we had it done)

- Q: the best way to thermal insulate and water proofing of rcc slabs economical, may be some poly urethane material or whatever but should be very effective and light weight.

- POROSIL A specially graded Light Weight Insulating Aggregate for loose fill insulation in Cavity Wall and over Suspended/False Ceiling. # 100% inorganic and Asbestos free. It will not rot, emit odours or attract vermin. # Light in weight and easy to handle. # POROSIL is the only insulating material which is Non-toxic and non-flammable at the time of fire. # Reduces unwanted heat flow making living comfortable. # Reduces the Air Conditioning Power Consumption upto 20 to 30%

- Q: ... building code max. (R-50)???

- The roof can also be heated enough to melt snow/ice by the sun. I wouldn't assume it's being caused by heat escaping from inside. That said, just because you have R50 doesn't mean it's perfect - it's not. Some heat will still escape. Prefect insulation is not feasible.

- Q: should thermal insulation ever be applied directly to the underside of a roof top?

- On pole barns with metal roofing it is common to have a thin layer of insulation directly under the roofing. This prevents condensation from forming.

- Q: if you had snow and all the snow is off your roof and the house nex store has snow do we need insulation?

- That is very observant of you. Yes this could indicate that you are losing more heat than normal through your roof. Though, you do want to be careful in the placement of any new insulation, you will want to avoid any vents that are there for ventilation of heat and moisture in the summer and any recessed lighting fixtures as to not cause an overheating problem with them. This is a good investment and it will pay you back in heating and cooling cost for years to come.

- Q: I have a vented metal roof. WV winters

- Check into heat tape tied to pipe, with insulation wrapped around that. turns on when freezing temperatures. insulation by itself, will not stop it from freezing if left for long periods without water moving through it. .

- Q: attic is 400 sq ft.there are 4 round 6'' Vents in soffit,and 2 roof vents-12"x12".Rock wool,blown in,R/30 NO VAPOR BARRIER.Why the mold?no gable or ridge vent either.How do i fix this?There are baffles in attic,rafters are not blocked.

- You still don't have enough attic ventilation. Definitely need more soffit vents. Roof mounted turbine vents that turn in the wind help suck more air through the attic. This coupled with at least one gable end vent should stop further mold. Removing old mold is a hassle, but can be done using diluted bleach in a lawn pump sprayer. A respirator will be needed to ensure you can breathe while applying the bleach solution.

- Q: Above the trailer roof is a metal pitched roof with no soffit and lots of air-flow. I plan to recess the insulation 6" to allow airflow. There is a suggestion that I need a vapor barrier. If I use a vapor barrier, won’t water collect between the roof and the barrier. I was thinking if using strapping crosswise every 4” to act as a channel for water runoff. Any ideas?

- The roof is already a vapor barrier, you won't need 2.

- Q: Can I install rigid insulation between roof decking and shingles on a sloped roof?

- Lot of info missing to give you a good answer. Thickness of insulation. Slope of roof. But what it really comes down to is the building code in your area, contact local building inspector,

Send your message to us

Gaf Tapered Roofing Insulation Aluminum Foil with LDPE Heat Seal for Bubble Foil Facing Production

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 90 cm²

- Supply Capability:

- 33412 cm²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords