Aluminum Extrusion Profiles Australia - 6000 Series Aluminum Profile Extrusion Manufacturer

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft,durable, lightweight, ductile and malleablemetal with appearance ranging from silvery to dull gray,depending on the surface roughness. It is nonmagnetic and does not easilyignite. A fresh film of aluminium serves as a good reflector (approximately92%) of visible light and an excellent reflector (as much as98%) of medium and far infrared radiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the density and stiffnessof steel. It iseasily machined,cast, drawn and extruded.

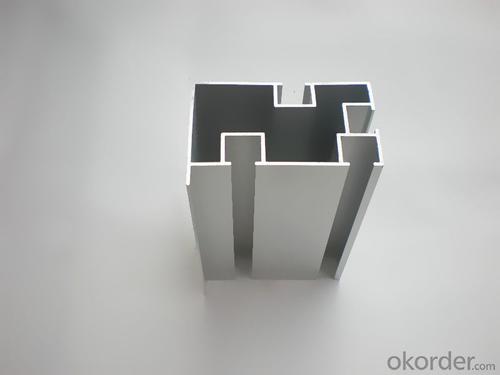

Aluminum Profile

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

- Q: What are the different surface protection options available for aluminum profiles?

- There are several surface protection options available for aluminum profiles, including anodizing, powder coating, painting, and laminate coating. Anodizing is a process that creates a durable and corrosion-resistant layer on the surface of the aluminum. Powder coating involves applying a dry powder to the surface, which is then heated to form a protective layer. Painting involves applying liquid paint to the surface, providing both protection and aesthetic appeal. Laminate coating involves applying a thin layer of protective material, such as plastic or wood, to the surface of the aluminum. Each option offers different benefits and is suitable for various applications.

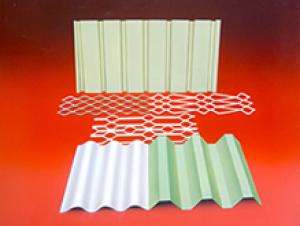

- Q: This question asks about the variety of colors offered for aluminum profiles used in exterior siding and trim applications.

- <p>Aluminum profiles for siding and trimming are available in a wide range of colors to suit various architectural styles and design preferences. Common colors include white, black, brown, beige, and gray, which are popular for their neutrality and versatility. Additionally, there are bolder options such as red, blue, green, and yellow for more distinctive looks. Some manufacturers also offer custom color matching services for specific projects. The finishes can be powder-coated or anodized, providing durability and resistance to weathering. It's always best to check with specific manufacturers for the most up-to-date color offerings as they may introduce new colors or discontinue others based on market trends.</p>

- Q: What are the different bending radius options for aluminum profiles?

- The bending radius options for aluminum profiles vary depending on the specific profile design, thickness, alloy, and temper. Generally, aluminum profiles can be bent to a radius of 1.5 to 2 times the profile's thickness. However, this can be influenced by factors such as the alloy's strength, the profile's cross-sectional shape, and whether it has internal or external radii. For thicker profiles, the minimum bending radius tends to be larger, while thinner profiles can achieve smaller bending radii. It is important to note that attempting to bend a profile below its recommended minimum bending radius can lead to deformation, cracking, or even failure. In some cases, aluminum profiles can undergo cold bending, where they are bent without the need for heating. Cold bending allows for tighter radii and can be achieved through specialized bending equipment or processes. However, it is essential to consult the manufacturer's specifications or seek professional advice to determine the appropriate bending radius options for specific aluminum profiles.

- Q: What are the advantages of using aluminum profiles in the renewable energy sector?

- The utilization of aluminum profiles in the renewable energy sector brings forth numerous benefits. To begin with, these profiles possess a combination of lightness and strength, rendering them ideal for the construction of solar panel frames, wind turbine components, and other renewable energy infrastructure. Their favorable strength-to-weight ratio facilitates easy transportation and installation, thereby reducing costs and enhancing efficiency. Moreover, aluminum profiles exhibit exceptional resistance to corrosion, making them suitable for outdoor applications, even in harsh environments. This durability ensures the stability and functionality of renewable energy infrastructure over extended periods, including coastal areas and corrosive surroundings. Furthermore, aluminum profiles offer remarkable thermal conductivity, a crucial attribute for efficient heat dissipation in renewable energy systems. This property facilitates efficient cooling of solar panels, wind turbine generators, and other components, thereby improving their performance and lifespan. Additionally, aluminum is a sustainable material that can be effortlessly recycled. With the renewable energy sector's focus on promoting sustainability, the utilization of aluminum profiles aligns perfectly with the industry's objectives. Aluminum can be recycled repeatedly without compromising its properties, reducing the need for primary aluminum production and minimizing the carbon footprint of renewable energy projects. Lastly, aluminum profiles provide design flexibility and versatility. They can be easily customized and fabricated into various shapes and sizes, allowing for seamless integration into different renewable energy applications. This adaptability empowers engineers and designers to optimize the use of aluminum profiles, resulting in improved energy efficiency and overall system performance. In conclusion, the utilization of aluminum profiles in the renewable energy sector offers advantages such as lightweight strength, corrosion resistance, thermal conductivity, sustainability, and design flexibility. By incorporating aluminum profiles into renewable energy infrastructure, we can enhance the efficiency, durability, and environmental sustainability of the sector.

- Q: Is the aluminum profile insulated and broken hot?

- Yes, the name is not the same, the professional name is "broken hot aluminum alloy", most people used to call "broken bridge aluminum"

- Q: How do aluminum profiles perform in terms of weather resistance?

- Aluminum profiles exhibit remarkable weather resistance due to the unique qualities of aluminum itself, such as its resistance to corrosion and ability to endure harsh environmental conditions. To enhance their weather resistance, aluminum profiles are typically coated or anodized, providing long-lasting durability and protection against different weather elements. The corrosion resistance of aluminum is especially advantageous for outdoor applications. When exposed to oxygen, aluminum naturally forms an oxide layer, serving as a protective barrier against rust and deterioration. Consequently, aluminum profiles are highly resistant to moisture, rain, and humidity, making them suitable for use in coastal areas or regions with high levels of precipitation. Moreover, aluminum profiles also possess resistance against UV radiation. The application of surface treatments, such as powder coating or anodizing, adds an extra layer of defense against the sun's harsh rays. Consequently, aluminum profiles do not fade, chip, or crack when exposed to prolonged sunlight, ensuring their original appearance and structural integrity are preserved over time. Concerning extreme weather conditions, aluminum profiles are specifically designed to withstand high winds, extreme temperatures, and even severe storms. They possess excellent mechanical properties, including high strength and stiffness, enabling them to bear heavy loads and resist deformation. As a result, aluminum profiles are ideal for applications in construction, architecture, and outdoor infrastructure projects where weather resistance is of utmost importance. In conclusion, aluminum profiles exhibit exceptional weather resistance. Their inherent corrosion resistance, combined with the availability of various surface treatments, ensures their ability to endure a wide range of weather conditions while maintaining their structural integrity and aesthetic appeal.

- Q: What are the aluminum packaging methods?

- Common1 each cotton covered cotton;2 each sleeve;3 coat big bag plastic sealing;4, two wire line;5, three, wrapping paper;6, outsourcing cotton (outsourcing paper).....

- Q: Can aluminum profiles be used in interior design applications?

- Yes, aluminum profiles can be used in interior design applications. They are versatile, lightweight, durable, and available in various finishes and designs. Aluminum profiles can be used for creating furniture, partitions, shelving, lighting fixtures, decorative elements, and more, adding a modern and sleek aesthetic to interior spaces.

- Q: This question asks about the various types of aluminum profiles that are utilized in interior design applications.

- <p>Aluminum profiles are widely used in interior design for their strength, durability, and aesthetic appeal. Common types include: 1. Linear Profiles for creating sleek lines in furniture and architectural elements; 2. Structural Profiles for load-bearing structures like beams and columns; 3. Decorative Profiles for ornamental purposes, such as moldings and trims; 4. Frame Profiles for framing pictures, mirrors, and other wall-mounted items; 5. Slatwall Profiles for versatile display systems in retail spaces; 6. Handrail Profiles for stairways and balconies, ensuring safety and style; 7. Window and Door Profiles for modern, lightweight, and energy-efficient applications. Each type is chosen based on the specific design requirements and functional needs of the space.</p>

- Q: Features of aluminum profiles

- MachinabilityThe machinability of aluminum profile is excellent. In a variety of wrought aluminum and cast aluminum alloys, and in the various states after which these alloys are produced, the machining characteristics vary considerably, which requires special machine tools or techniques.FormabilityThe specific tensile strength, yield strength, ductility, and the corresponding work hardening rate govern the amount of allowable deformation.RecyclingAluminum is highly recycled, and the characteristics of recycled aluminum are almost the same as those of native aluminum.

Send your message to us

Aluminum Extrusion Profiles Australia - 6000 Series Aluminum Profile Extrusion Manufacturer

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords