Aluminum Extrusion Profiles Architectural & Ornamental 6063-T5 Anodizing Electrostatic Spray Coating

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 kg

- Supply Capability:

- 20000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Extrusion Profiles & Products

Among the wide range of building materials supplied by CNBM, custom aluminum (or 'aluminium' in British English) extrusion profiles stand out, designed specifically for construction-related applications. These profiles are meticulously manufactured and undergo a high-quality anodization process to ensure both durability and aesthetic appeal. If you have a design, simply send it to us, and we will bring your vision to life in real products.

Aluminum Extrusion Process

Aluminum alloy parts and profiles are produced either through die-casting or using a precision-designed extrusion die. The most commonly used aluminum alloy in the building industry is 6063-T5.

Aluminum round bars serve as the primary raw material for aluminum profile extrusion.

We maintain a stock of extended aluminum bars in preparation for profile extrusion.

Our aluminum extrusion workshop.

;Our aluminum extrusion workshop.

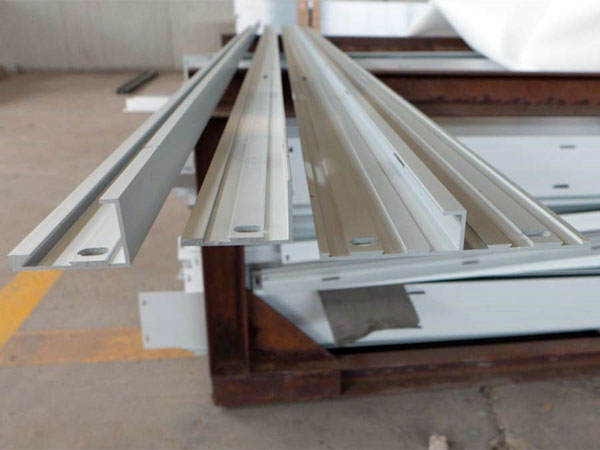

The warehouse where extrusion aluminum profiles are stored.

Aluminum Metalworking Process

Similar to other metal fabrication processes, aluminum profiles may also require the transformation of semi-finished materials into final products through cutting, punching, drilling, or CNC machining. Specialized aluminum fabrication work is conducted in our dedicated fabrication shops (fab shops). Common methods include cutting, drawing, folding, forging, machining, punching, shearing, stamping, and welding to reshape or create new products. Our fab shops also provide finishing services such as deburring, polishing, coating, and painting to ensure the highest quality of the final product.

Director Hailong addressing and resolving machining issues.

Our advanced aluminum fabrication shop.

Our advanced aluminum fabrication shop.

Specially designed 90-degree angle turrets within the mold punch holes in the aluminum profile.

Aluminium Anodizing & Dyeing

An anodized finish is a clear or colored coating chemically applied to the surface of aluminum. This process not only thickens the natural oxide layer on aluminum parts but also protects them from corrosion. Additionally, anodizing alters the crystal structure near the surface of the aluminum alloy, allowing us to impart vibrant colors to the metal. Depending on the size and intended use of the aluminum component, anodizing can be categorized into two methods: 'long-profile anodizing' and 'small-widget anodizing.'

Long-Profile Anodizing

We anodize long profiles by stacking them in a large metal basket.

The metal basket is submerged in a sizable oxidation pond containing chemicals.

Aluminum profiles are typically immersed in the oxidation pond for approximately 20 to 40 minutes.

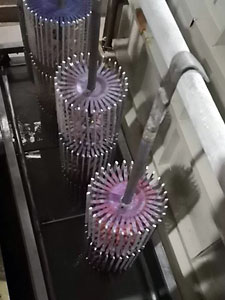

Small-Widget Anodizing

Anodizing small aluminum parts to a vibrant red hue.

Anodizing small aluminum parts to achieve a vibrant blue color.

Anodizing small aluminum parts to a shining gold color.

Grippers or holders used in the anodizing process for small and thin aluminum flashings.

Aluminum Products We Manufacture

A die-cast aluminum item anodized in a clear aluminum color.

A die-cast aluminum item with a white electrostatic spray coating.

An aluminum profile bar designed for use in camping tents.

CNC milled aluminium extrusion heat sink radiator.

CNC milled aluminium extrusion heat sink radiators.

CNC milled aluminium extrusion heat sink radiators.

Frosted-anodized aluminum flashing designed for roofing system.

T-shaped aluminum industrial rail system with fixing and drainage holes.

T-shaped aluminum industrial rail system with fixing and drainage holes.

Cross-section view of aluminum profiles in both L and T shapes.

A wooden case for packaging bundled aluminum profiles wrapped with protective film.

Our inventory of extruded aluminum profiles with various section shapes.

Aluminum profile samples with different anodized colors: brown, gold, champagne, and black.

An aluminum part anodized to achieve a gold color.

Aluminum alloy tubes anodized and dyed in violet and blue colors.

Last Updated: 2024-09-24

- Q: What are the different bending options available for aluminum profiles?

- There are several bending options available for aluminum profiles, depending on the specific requirements and desired outcomes. Some of the common bending methods for aluminum profiles include: 1. Roll Bending: This method involves passing the aluminum profile between a series of rollers to achieve the desired bend. Roll bending is typically used for larger and thicker profiles, as it provides a gradual and consistent bend. 2. Press Bending: Press bending uses a hydraulic or mechanical press to apply force and shape the aluminum profile into the desired form. This method is suitable for both small and large profiles and can achieve various bend angles. 3. Mandrel Bending: Mandrel bending involves inserting a mandrel, which is a rod or tube, into the aluminum profile to maintain its shape during the bending process. This method ensures precise and uniform bends, making it suitable for complex shapes and tight radius bends. 4. Stretch Bending: Stretch bending applies controlled stretching forces to the aluminum profile, allowing it to flex and bend. This method is often used for profiles with large radii and gentle curves. 5. Rotary Draw Bending: Rotary draw bending utilizes a die and a rotating arm to bend the aluminum profile around a specific radius. This method is highly accurate and commonly used for precise and repeatable bends. 6. Heat Bending: Heat bending involves applying heat to the aluminum profile to soften it before bending. Once the desired bend is achieved, the profile is cooled to retain its new shape. This method is suitable for profiles with complex shapes and sharp angles. Each bending option has its advantages and limitations, and the selection depends on factors such as the profile size, shape complexity, bend angle, and required precision. Consulting with a professional or a bending specialist is recommended to determine the most appropriate bending method for specific aluminum profile applications.

- Q: Can aluminum profiles be used in marine vessel manufacturing?

- Marine vessel manufacturing can indeed utilize aluminum profiles. Boats and other marine vessels are commonly constructed using aluminum due to its exceptional characteristics. Lightweight, durable, and resistant to corrosion, aluminum proves to be an ideal material for marine environments. It can endure the effects of saltwater exposure, a prevalent concern in marine applications. Moreover, aluminum profiles can be effortlessly shaped, welded, and interconnected, facilitating efficient and customizable vessel designs. This adaptability renders aluminum highly appealing to boat builders and manufacturers.

- Q: What kind of self tapping screw can attack aluminum profile?

- Self tapping screws are used for connecting between thin metal plates. When connecting to the connecting piece for the threaded hole, then tapping screws into the threaded hole of the connecting piece. Because of the self tapping screw thread surface has higher hardness (more than 45HRC), the attack a thread in the threaded hole of the connecting piece, thereby forming a connection.Aluminum material than steel soft, generally in accordance with GB screws can be of aluminum, is recommended to hit bottom hole in the needed position.The following is the national standard for self tapping screws:GB/T15856.1-2002 cross recessed countersunk head tapping screws, material: 20Mn 15MnBGB/T15856.2-2002 cross recessed countersunk head drilling self tapping screw, material: 20Mn 15MnBGB/T15856.3-2002 cross recessed semi countersunk head drilling self tapping screw, material: 20Mn 15MnB

- Q: Does aluminum alloy profile conduct electricity?

- Aluminum conducts well, and aluminium alloys must also be electrically conductive. But aluminum alloys contain impurities such as silicon and magnesium

- Q: How do aluminum profiles contribute to sustainable infrastructure development?

- Aluminum profiles play a significant role in promoting sustainable infrastructure development in various ways. Firstly, aluminum is a lightweight material, which means it requires less energy during transportation and installation compared to other heavy materials like steel. This reduces greenhouse gas emissions and the overall carbon footprint associated with construction projects. Additionally, aluminum profiles have excellent durability and corrosion resistance, allowing them to withstand harsh environmental conditions and extend the lifespan of infrastructure projects. This durability reduces the frequency of repairs and replacements, leading to reduced waste generation and resource consumption. Furthermore, aluminum is a highly recyclable material, with the ability to be infinitely recycled without losing its original properties. This promotes a circular economy by minimizing the need for primary aluminum production and reducing the demand for raw materials. The recycling process of aluminum also requires significantly less energy compared to primary production, resulting in reduced energy consumption and lower emissions. Moreover, aluminum profiles offer design flexibility and compatibility with various construction methods, allowing for innovative and sustainable infrastructure solutions. They can be easily integrated into energy-efficient systems, such as solar panels or LED lighting, to further enhance sustainability. Overall, the use of aluminum profiles in infrastructure development contributes to a more sustainable built environment by reducing energy consumption, minimizing waste generation, promoting recycling, and enabling the implementation of energy-efficient solutions.

- Q: Can aluminum profiles be used in aerospace applications?

- Yes, aluminum profiles can be used in aerospace applications. Aluminum has been widely used in the aerospace industry for many years due to its various advantageous properties. Aluminum profiles are lightweight, which is crucial in aerospace applications as it helps reduce the overall weight of the aircraft, resulting in improved fuel efficiency and increased payload capacity. Additionally, aluminum profiles possess high strength-to-weight ratio, making them strong enough to withstand the stress and forces experienced during flight. Aluminum is also corrosion-resistant, which is beneficial in the harsh and corrosive environment of aerospace. Furthermore, aluminum profiles can be easily machined and formed into complex shapes, allowing for greater design flexibility. Overall, the combination of lightweight, strength, corrosion resistance, and ease of fabrication makes aluminum profiles an excellent choice for various aerospace applications such as aircraft frames, wings, fuselages, and structural components.

- Q: Are aluminum profiles suitable for playground equipment?

- Yes, aluminum profiles are suitable for playground equipment. Aluminum is a lightweight and durable material that is commonly used in various industries, including playground equipment manufacturing. It is known for its strength and resistance to corrosion, making it suitable for outdoor applications. Aluminum profiles provide structural stability and can withstand the weight and forces exerted during play. Additionally, aluminum is non-toxic and does not rust, ensuring the safety and longevity of the playground equipment. The versatility of aluminum allows for the creation of various shapes and designs, providing endless possibilities for innovative and attractive playground structures. Overall, aluminum profiles are a suitable choice for playground equipment due to their strength, durability, and safety features.

- Q: Are aluminum profiles suitable for use in flooring systems?

- <p>Yes, aluminum profiles can be used for flooring systems. They are known for their strength, durability, and resistance to corrosion, making them ideal for various flooring applications. Aluminum profiles can be used to create modular flooring systems, providing a lightweight and easy-to-install solution. They can also be used in conjunction with other materials to create hybrid flooring systems, offering a combination of benefits such as thermal insulation, acoustic performance, and structural integrity.</p>

- Q: What do the 6063 and T5 represent in the aluminum profile 6063-T5?

- Alloy number: our country's current general is the American Aluminum Association "Aluminium Association" numberExamples are as follows: 1070-H14 (pure aluminum)2017-T4 (heat treatment alloy)3004-H32 (non heat treated alloy)2.1 first digit: indicates the main addition of alloying elements1: pure aluminum2: the main alloy element added copper3: the main alloying elements are manganese or manganese and magnesium4: the main alloy element is added silicon

- Q: How do aluminum profiles perform in terms of magnetic properties?

- Aluminum profiles do not possess strong magnetic properties. Aluminum is considered non-magnetic as it is not attracted to magnets. This is due to its atomic structure, which does not facilitate the alignment of magnetic domains necessary for magnetic attraction. Therefore, aluminum profiles are generally not affected by magnetic fields and do not have any significant magnetic properties.

Send your message to us

Aluminum Extrusion Profiles Architectural & Ornamental 6063-T5 Anodizing Electrostatic Spray Coating

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 kg

- Supply Capability:

- 20000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches