Aluminum Embossed Sheet/Plate for Non-Slip Floor and Trailer Siding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

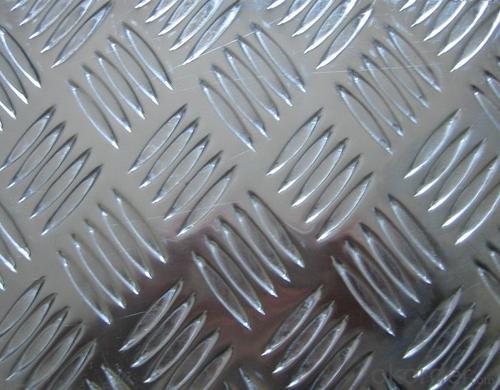

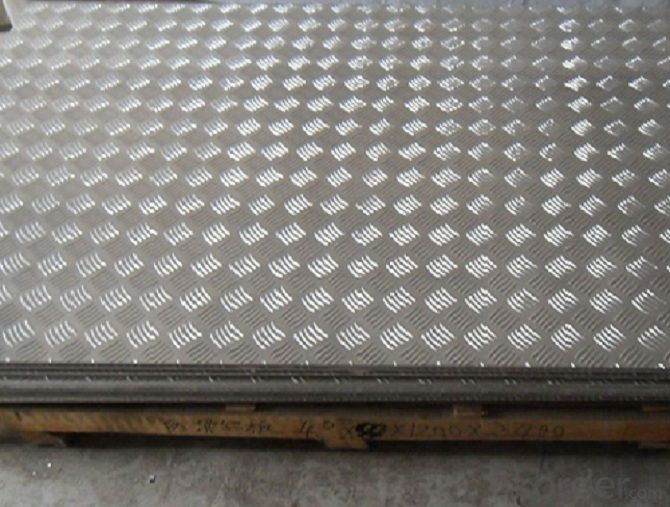

Aluminium Embossed Sheet/ Plate for Non-slip Floor

l Product Specification:

Serise and Temper | Alloys: 1060/1100/3003 ETC Temper: 0-H24 |

Thickness | 0.2mm - 10.0mm |

Treatment | Smooth surface ,and Needle Embossed |

Width & Length | Width:1000-1900mm or Custom Length:2000-6000mm or Custom |

Packing Detail | Export standard packing or according to customer's requirement. |

Technical Standard | GB/T 3880-2006 |

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirement

Delivery detail: about 20 days from received oiginal L/C or advance payment

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

l CNBM World Wide

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: How much is one ton of aluminium plate?

- For aluminum alloy, the aluminum alloy and other metal elements, according to different metallic elements, can be divided into eight branches, 1-8 etc.. According to the contents of various metallic elements, each department can be divided into different grades of alloy, such as 8011505230031060, each kind of alloy prices are not the same. In addition, the different processing thickness, width, the process used, the cost is not the same, so the specifications are different, the price is different. As for the aluminum plate, how much is it a ton? I think you have a better answer.

- Q: This question asks for methods to maintain and repair aluminum sheets once they have been installed.

- <p>To maintain and repair aluminum sheets after installation, follow these steps: Regularly clean the surface with a soft cloth and mild detergent to remove dirt and grime. Avoid abrasive materials that can scratch the surface. For minor scratches or dents, use aluminum filler or touch-up paint that matches the sheet's color. Apply the filler or paint carefully, following the manufacturer's instructions. For more severe damage, consider hiring a professional to assess and repair the damage to ensure structural integrity. Always check for any signs of corrosion and address them promptly to prevent further damage. Regular maintenance will prolong the life of aluminum sheets and keep them looking their best.</p>

- Q: I'm thinking of starting raised beds for a vegetable garden. I'm thinking about a shallow aluminum stock tank, about 12 in. deep x 4 ft. long. Having limited sunlight available, these could be moved around the yard and tended to easily. Any ideas? Aluminum with soil? Any effects? Holes will be drilled in the bottom for drainage. Thanks!

- Aluminum has good corrosion resistance, it will work fine. With a big tub like that you can grow a lot of delicious veggies. Make sure you provide enough drainage for the size of the tub. Good luck and happy gardening!

- Q: How to clean the engine oil and kerosene on the surface of aluminum sheet?

- you can buy a bottle of petroleum ether in chemical raw material shop, it will be clean after rubbing, or you can buy solvent oil.

- Q: Is it possible to use aluminum sheets for indoor purposes?

- <p>Yes, aluminum sheets can be used for indoor applications. They are commonly used in interior design for their durability, lightweight, and resistance to corrosion. Aluminum sheets are often utilized in the construction of furniture, decorative panels, and even as a material for interior walls and ceilings. Their ease of maintenance and ability to be recycled make them an environmentally friendly option for indoor use.</p>

- Q: Can aluminum sheets be used for outdoor applications?

- Yes, aluminum sheets can be used for outdoor applications. Aluminum is a durable and corrosion-resistant material, making it suitable for a wide range of outdoor uses. It is commonly used for roofing, siding, gutters, and outdoor signage. Aluminum sheets have high strength-to-weight ratio, which makes them ideal for applications where a lightweight yet sturdy material is required. Additionally, aluminum naturally forms a protective oxide layer that helps protect it from the elements, making it a reliable choice for outdoor environments.

- Q: Can 101 aluminum sheets be recycled?

- Certainly, it is possible to recycle 101 aluminum sheets. Aluminum possesses a remarkable recyclability, boasting an impressively efficient recycling procedure. Through the act of recycling aluminum sheets, we not only preserve valuable resources but also conserve energy and diminish greenhouse gas emissions. Additionally, recycling aluminum aids in the reduction of landfill waste and curtails the necessity for fresh aluminum ore mining. Consequently, we highly recommend recycling 101 aluminum sheets to actively contribute towards a future that is more sustainable and environmentally conscious.

- Q: What precautions should be taken while handling aluminum sheets to ensure safety?

- <p>When working with aluminum sheets, it's important to take certain safety measures. Always wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and a dust mask to protect against sharp edges and metal dust. Ensure good ventilation to avoid inhaling aluminum dust, which can be harmful. Use proper tools designed for metal work to prevent accidents. Keep the work area clean and free from clutter to minimize trip hazards. Be cautious of electrical hazards if using power tools, and ensure all tools are in good working order. Finally, be aware of the fire hazard potential of aluminum, especially when cutting or welding, and have fire extinguishers readily available.</p>

- Q: Can aluminum sheet be used for automotive applications?

- Yes, aluminum sheet can be used for automotive applications. It is commonly used in the manufacturing of car bodies, hoods, doors, and other structural components due to its lightweight, corrosion resistance, and high strength-to-weight ratio.

- Q: What are the different manufacturing methods for aluminum sheets?

- Aluminum sheets can be manufactured using various methods, each possessing its own unique characteristics and applications. 1. Rolling, the most commonly employed method, involves passing large aluminum slabs through a series of rollers to reduce thickness and increase length. This process ensures consistent thickness and excellent surface finish. 2. Another method, extrusion, utilizes a heated aluminum billet forced through a die, resulting in a continuous sheet. Extrusion allows for the creation of complex shapes and profiles, making it suitable for applications in building construction and automotive components. 3. Casting involves pouring molten aluminum into a mold, allowing it to cool and solidify into a sheet shape. This method is often used for producing thicker sheets or those with specific alloy compositions. Casting offers unique properties and is prevalent in industries such as aerospace and defense. 4. Cladding entails bonding a thin layer of aluminum to another material like steel or composite materials. This combines the desirable qualities of aluminum, such as corrosion resistance and lightweight, with the strength and durability of the base material. Clad aluminum sheets find common use in construction, transportation, and electrical industries. 5. Powder metallurgy involves forming aluminum sheets from powdered aluminum particles. The powder is compacted into the desired shape and then sintered at high temperatures to fuse the particles together. This method is ideal for producing complex shapes and can improve mechanical properties. Considering the desired properties, application, and cost considerations, it is crucial to select the most appropriate manufacturing method for aluminum sheets based on the specific project requirements.

Send your message to us

Aluminum Embossed Sheet/Plate for Non-Slip Floor and Trailer Siding

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords