Aircraft Aluminum Sheets - Aluminum Composite Panel PE or PVDF - Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

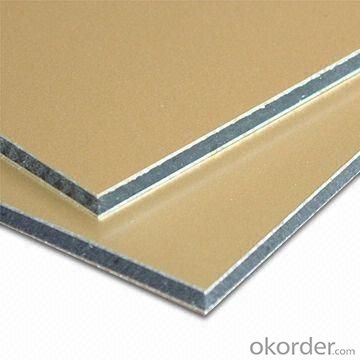

Structure of Aluminium Composite Panel Description:

Aluminum Composite Panel is a composite material made of aluminum and non-combustible mineral filled core. Though the core material does contain a small amount of combustible polyethylene, the main ingredient of the non-combustible mineral filled core does not permit the proliferation of flame and restricts smoke. It is a fire-safe material that passes mandatory requirements for exterior and interior application.It is an ideal material for external claddings, roof of pedestrian passage and other architectural applications.

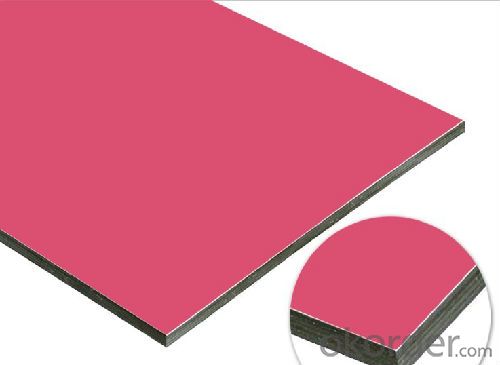

Main Features of Aluminium Composite Panel:

1) Fireproof and water resistant, excellent heat and sound insulation

2) Excellent surface flatness and smoothness

3) Superior weather, corrosion and pollutant resistance

4) Even coating, various colors

5)Super peeling strength

6) Superior impact resistance

7) Lightweight and easy to process

8) Easy to maintain

Images of Aluminium Composite Panel:

Aluminium Composite Panel Specification:

Panel Thickness(mm) | 2mm-8mm |

Aluminium Skin Thickness(mm) | 0.04mm-0.5mm |

Width(mm) | until to 2000mm |

Length(mm) | until to 10000mm |

FAQ of Aluminium Composite Panel

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000㎡.

b. Now which countries do you export your goods?

----Now we export to South East Asia,Africa, North America,South America ect.

- Q: Can the aluminum sheets be used for manufacturing power transmission lines?

- Yes, aluminum sheets can be used for manufacturing power transmission lines.

- Q: Can aluminum sheets be used in outdoor environments?

- Yes, aluminum sheets can be used in outdoor environments. Aluminum is a highly versatile and durable material that is well-suited for outdoor applications. It has excellent resistance to corrosion, which makes it ideal for withstanding the elements such as rain, snow, and UV radiation. Additionally, aluminum sheets are lightweight yet structurally strong, making them suitable for various outdoor projects such as roofing, siding, and cladding. Furthermore, aluminum is non-combustible, making it a safe choice for outdoor environments. Overall, aluminum sheets provide a reliable and long-lasting solution for outdoor applications.

- Q: I got nauseous the other day and that day one thing I ate was hamburger baked for 1 hour on aluminum foil with tomatoes mixed in. Is it possible the upset stomach was caused by the tomatoes reacting with the foil?

- You can use it in microwave

- Q: What is the typical hardness of aluminum sheets?

- The typical hardness of aluminum sheets can vary depending on the specific alloy and temper. However, aluminum sheets generally have a hardness ranging from 40 to 70 on the Brinell hardness scale (HB). This level of hardness allows aluminum sheets to be easily formed, machined, and fabricated, making them suitable for a wide range of applications in industries such as aerospace, automotive, construction, and manufacturing. It is important to note that the hardness of aluminum sheets can be further enhanced through heat treatment processes, such as annealing or hardening, to meet specific requirements and improve their mechanical properties.

- Q: What are the different methods of surface finishing for aluminum sheet?

- There are several methods of surface finishing for aluminum sheet, including anodizing, painting, powder coating, polishing, and brushing.

- Q: How do aluminum plates open holes?

- The opening of the aluminum plate is a relatively simple process,You can do that with a micro electric device like an electric drill or a grooving machine

- Q: What are the different types of surface treatments available for painted aluminum sheets?

- Painted aluminum sheets can undergo a variety of surface treatments to enhance their appearance, durability, and protection against corrosion and damage. Anodizing is a commonly used surface treatment where aluminum sheets are immersed in an electrolytic solution and an electric current is passed through them. This process forms a protective oxide layer on the surface, improving corrosion resistance and providing a base for painting or other decorative finishes. Another popular treatment is powder coating, which involves applying a dry powder to the aluminum's surface and then heating it to create a tough, protective layer. This coating is known for its durability, resistance to fading and chipping, and ability to offer a wide range of colors and finishes. Apart from anodizing and powder coating, there are other surface treatments available for painted aluminum sheets. Chemical conversion coating entails applying a chemical solution to create a protective layer, while laminate coatings involve adding a thin film or laminate for additional protection and decoration. In conclusion, the various surface treatments for painted aluminum sheets provide several advantages, such as improved appearance, durability, and corrosion resistance. The choice of treatment depends on the specific requirements and desired outcomes for the aluminum sheets.

- Q: This question asks about the ability of aluminum sheets to withstand weather conditions without deteriorating.

- <p>Aluminum sheets have excellent weathering resistance. They are highly resistant to corrosion and oxidation, which makes them suitable for outdoor applications. Aluminum forms a protective oxide layer when exposed to air, which prevents further corrosion. This property allows aluminum sheets to maintain their appearance and structural integrity over time, even in harsh weather conditions. Additionally, aluminum can be coated or anodized to further enhance its resistance to weathering.</p>

- Q: This question asks for signs or indicators that would suggest whether a roof needs to be replaced or repaired using aluminum sheets.

- <p>To determine if your roof needs replacement or repair with aluminum sheets, look for the following signs: visible rust or corrosion, especially on the seams and fasteners; sagging or buckling in the roof surface; leaks or water damage inside your home; and excessive noise during rain or wind. If the damage is widespread or the roof is old, replacement might be necessary. However, if the damage is limited to specific areas, repairs could suffice. It's always best to consult with a professional roofer for an accurate assessment.</p>

- Q: The furnace above is only hot enough to melt lead, but isn't hot enough to melt aluminum. I'm not looking for a blowtorch, or something too expensive or could melt gold, but just something that i can buy and is like the one above but isn't that expensive and can melt aluminum. Thanks!

- Aluminum melts below 1300F These gold and silver melters like the one in the link go to 2000F or more and should work for aluminum. I guess more small melters of metals want to melt gold and silver than aluminum.

Send your message to us

Aircraft Aluminum Sheets - Aluminum Composite Panel PE or PVDF - Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords