Lightweight Aluminum Sheets White - Aluminium Composite Panel PE/PVDF - Good Price - High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

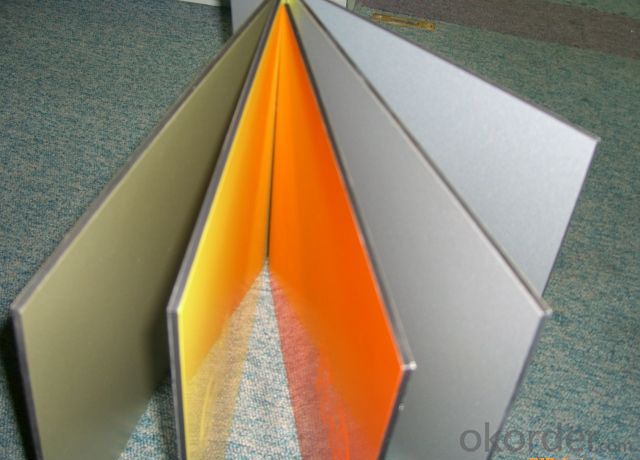

Structure of Aluminium Composite Panel Description:

Aluminum Composite Panel is a composite material made of aluminum and non-combustible mineral filled core. Though the core material does contain a small amount of combustible polyethylene, the main ingredient of the non-combustible mineral filled core does not permit the proliferation of flame and restricts smoke. It is a fire-safe material that passes mandatory requirements for exterior and interior application.It is an ideal material for external claddings, roof of pedestrian passage and other architectural applications.

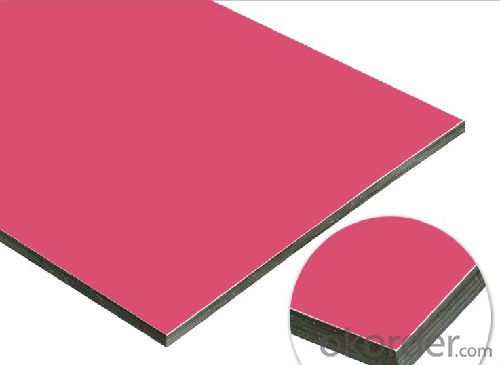

Main Features of Aluminium Composite Panel:

1) Fireproof and water resistant, excellent heat and sound insulation

2) Excellent surface flatness and smoothness

3) Superior weather, corrosion and pollutant resistance

4) Even coating, various colors

5)Super peeling strength

6) Superior impact resistance

7) Lightweight and easy to process

8) Easy to maintain

Images of AluminiumComposite Panel:

PE/PVDF Aluminium Composite Panel Specification:

| Width(mm) | 1220 | 1250 | 1500 | |||||

| Length(mm) | 2440 | Or according to customer's request | ||||||

| Panel thickness(mm) | 2 | 3 | 4 | 5 | 6 | |||

| Aluminum thickness(mm) | 0.10 | 0.12 | 0.15 | 0.18 | 0.21 | 0.3 | 0.4 | 0.5 |

| Coating | PVDF | PE | Brush | Mirror | Glossy | Wood and stone texture | ||

FAQ of Aluminium Composite Panel:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 20000㎡.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: What are the different methods of bending aluminum sheets?

- There are several methods of bending aluminum sheets, each with its own advantages and limitations. Some of the commonly used methods include: 1. Press Brake Bending: This method involves clamping the aluminum sheet between a punch and a die on a press brake machine. The sheet is then bent by applying force through the punch, which pushes against the die. Press brake bending is ideal for high-volume production and can achieve precise and consistent bends. 2. Roll Bending: Also known as a three-roll bending process, this method uses a set of three rollers to gradually bend the aluminum sheet into the desired shape. Roll bending is suitable for creating cylindrical or conical shapes and is often used in industries like automotive and aerospace. 3. Stretch Bending: In this method, the aluminum sheet is clamped at both ends while a stretching force is applied in the middle. The sheet is elongated and bent simultaneously, resulting in a curved shape. Stretch bending is commonly used for producing curved profiles with a smooth and uniform finish. 4. Heat Bending: By applying heat to the aluminum sheet, it becomes more pliable and can be easily bent into desired shapes. Heat bending is often performed using a heat gun or an oven to soften the metal, followed by manual or mechanical bending. This method is useful for creating complex and intricate shapes. 5. Incremental Bending: This method involves bending the aluminum sheet in multiple steps or increments, gradually increasing the bend angle with each step. Incremental bending allows for greater control over the bending process and is commonly used for forming U-shaped or V-shaped bends. 6. Roll Forming: In roll forming, the aluminum sheet is fed through a series of rollers, each gradually bending the sheet a little more. This continuous process is ideal for producing long and consistent bends, often used in the production of aluminum profiles and extrusions. It is worth noting that the choice of bending method depends on factors like the desired bend angle, the thickness and grade of the aluminum sheet, the required precision, and the volume of production.

- Q: Are aluminum sheets suitable for decorative purposes?

- Yes, aluminum sheets are suitable for decorative purposes. They are lightweight, durable, and versatile, making them ideal for various decorative applications such as wall panels, signage, furniture accents, and more. Additionally, aluminum sheets can be easily cut, shaped, and finished to achieve the desired decorative effect, making them a popular choice among designers and architects.

- Q: What are the primary components that make up aluminum sheets?

- <p>Aluminum sheets are primarily composed of aluminum, which is a lightweight and malleable metal. They are made from pure aluminum or aluminum alloys, which may include small percentages of other elements to enhance specific properties such as strength, corrosion resistance, or workability. Common alloying elements include copper, magnesium, manganese, silicon, and zinc. The exact composition varies depending on the specific grade of aluminum and its intended use. Pure aluminum is soft and not commonly used for sheets; instead, alloys are preferred for their improved strength and durability.</p>

- Q: This question asks about the various types of coatings that can be applied to aluminum sheets.

- <p>Aluminum sheets can be coated with various materials to enhance their properties such as corrosion resistance, appearance, and durability. Some common types of coatings include: 1. Anodizing, which creates a protective oxide layer on the surface. 2. Powder coating, a dry coating that is electrostatically applied and then cured at high temperatures. 3. Paint coating, which can be either liquid or powder-based and provides a decorative and protective layer. 4. Vinyl coating, which is a plastic coating applied for a smooth, matte finish. 5. Electrolytic coating, which involves depositing a thin layer of metal onto the aluminum surface. 6. Hot-dip coating, where aluminum is coated with a layer of zinc or other metals by dipping it into a molten bath. Each type of coating serves different purposes and has unique characteristics.</p>

- Q: Can aluminum sheet be used for aerospace applications?

- Certainly, aluminum sheet finds application in the aerospace industry. Owing to its advantageous characteristics, including being lightweight, highly robust, and resistant to corrosion, aluminum is extensively employed in this sector. It is frequently utilized in the fabrication of aircraft fuselages, wings, and structural elements. Aluminum sheets are commonly employed in the production of aircraft panels, where their exceptional strength-to-weight ratio facilitates enhanced fuel efficiency and greater payload capacity. Furthermore, aluminum sheets offer versatility and suitability for a wide range of aerospace applications due to their ease of forming, machining, and welding.

- Q: What is the standard thickness of aluminum sheets used for exterior building applications?

- <p>The typical thickness of aluminum sheets used for building exteriors ranges from 0.7mm to 1.2mm. This range is suitable for applications such as facades, cladding, and roofing. The specific thickness can vary depending on the structural requirements, wind loads, and the overall design of the building. Thicker sheets may be used for more robust structures or in areas with higher wind pressures, while thinner sheets can be used for lighter applications or when a more aesthetically pleasing finish is desired.</p>

- Q: How strong is aluminum per square inch, and at the same time how light is the aluminum per square inch?

- we have large aluminium sliding doors and in the summer time they twist and will not open why is this.

- Q: What are the different types of alloys used for powder-coated aluminum sheets?

- There are various types of alloys used for powder-coated aluminum sheets, including 3003, 5052, and 6061.

- Q: Is aluminum sheet resistant to UV rays?

- Yes, aluminum sheet is resistant to UV rays.

- Q: Can aluminum sheets be used in electrical applications?

- Yes, aluminum sheets can be used in electrical applications. Aluminum is a good conductor of electricity, and it is commonly used in various electrical components and applications. Aluminum sheets are often used as conductive materials in power transmission lines, bus bars, and electrical enclosures. They are also utilized in the manufacturing of capacitors, transformers, and heat sinks due to their excellent thermal conductivity properties. Additionally, aluminum sheets are lightweight and corrosion-resistant, making them suitable for electrical applications where weight and durability are important factors.

Send your message to us

Lightweight Aluminum Sheets White - Aluminium Composite Panel PE/PVDF - Good Price - High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords