Aluminum Circle Aluminium Round Plate DC&CC

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Specification

ALUMINIUM CIRCLE

2.Description

Aluminium foil has a shiny side and a matte side. The shiny side is produced when the aluminium is rolled during the final pass. It is difficult to produce rollers with a gap fine enough to cope with the foil gauge, therefore, for the final pass, two sheets are rolled at the same time, doubling the thickness of the gauge at entry to the rollers. When the sheets are later separated, the inside surface is dull, and the outside surface is shiny. This difference in the finish has led to the perception that favouring a side has an effect when cooking. While many believe that the different properties keep heat out when wrapped with the shiny finish facing out, and keep heat in with the shiny finish facing inwards, the actual difference is imperceptible without instrumentation.

Thin sheets of aluminium are not very effective at attenuating low-frequency magnetic fields. The shielding effectiveness is dependent upon the skin depth. A field traveling through one skin depth will lose about 63 percent of its energy (it is attenuated to 1/e = 1/2.718... of its original energy). Thin shields also have internal reflections that reduce the shielding effectiveness. For effective shielding from a magnetic field, the shield should be several skin depths thick. Aluminium foil is about 1 mil (25 µm); a thickness of 10 mils (250 µm) (ten times thicker) offers less than 1 dB of shielding at 1 kHz, about 8 dB at 10 kHz, and about 25 dB at 100 kHz.

3.Why you want to choose us?

We can supply the best quality and best service!

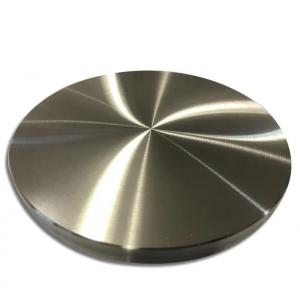

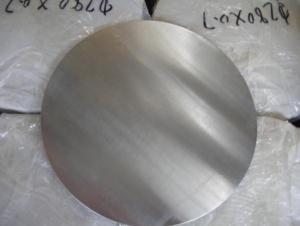

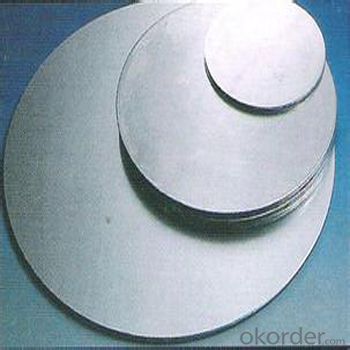

4.Pictures

5.FAQ

1)Can we supply samples?

Yes, we can!

2)What can you do if you have other quastions?

You can contact us freely at any time!

3)How about our payment term?

LC and TT and other.

- Q: Can 101 aluminum sheets be used in the production of solar reflectors?

- Solar reflectors can indeed utilize 101 aluminum sheets for their production. Aluminum is a highly utilized material within the solar sector, owing to its exceptional reflectivity and long-lasting nature. The term "101" pertains to the specific alloy composition of the aluminum, typically indicating either pure aluminum or a low alloy variation. Pure aluminum possesses superb reflective qualities, rendering it an ideal choice for solar reflectors that necessitate efficient redirection of sunlight towards solar cells or panels. Nevertheless, it is crucial to take into account other factors such as thickness, surface finish, as well as any additional coatings or treatments that may be essential for optimal performance in solar reflector applications.

- Q: This question asks for a comparison of aluminum sheets with other common materials used in building insulation, focusing on their properties and performance.

- <p>Aluminum sheets are lightweight and have excellent thermal conductivity, which can be both an advantage and a disadvantage in insulation. They reflect heat well, making them useful in radiant barrier applications, but they are poor insulators as they do not trap heat. In contrast, materials like fiberglass, cellulose, and mineral wool have lower thermal conductivity and are more effective at reducing heat transfer. These materials are better at insulating as they trap air, which is a poor conductor of heat. Foam insulation, such as polyurethane and polystyrene, also offers good thermal resistance due to their closed-cell structure. Overall, aluminum sheets are not typically used as primary insulation but can be effective in specific applications where heat reflection is desired.</p>

- Q: Can 101 aluminum sheets be used in architectural cladding?

- Certainly, architectural cladding can indeed utilize 101 aluminum sheets. The lightweight nature, durability, and resistance to corrosion make aluminum a favored option for architectural cladding. Specifically, grade 101 aluminum sheets find widespread use in architectural applications due to their impressive formability and easy workability. These sheets can be effortlessly cut, shaped, and joined to fashion tailor-made cladding solutions. Moreover, aluminum offers the possibility of being coated or anodized, allowing for enhanced aesthetics and added weather protection. Consequently, it is evident that 101 aluminum sheets prove suitable for various architectural cladding projects.

- Q: Explain the pros and cons of utilizing aluminum sheets in the construction of car body panels.

- <p>Aluminum sheets offer several advantages for car body panels, such as reduced weight, which can improve fuel efficiency and handling. They also have high resistance to corrosion, enhancing the vehicle's durability. Additionally, aluminum is easier to recycle, contributing to environmental sustainability. However, there are downsides, including higher cost compared to steel, which can affect the vehicle's price. Aluminum is also less malleable, making it more challenging to repair after accidents, potentially leading to higher repair costs. Furthermore, aluminum's lower strength compared to steel can necessitate thicker panels to achieve the same structural integrity, which may offset some of the weight savings.</p>

- Q: what's the size of gap while pressing 6mm aluminum sheet?

- choose the 8-10% of the thickness for two-sided gaps.

- Q: Could two pieces of aluminum sheets be welded together?

- sure, it does.

- Q: What is the typical corrosion resistance of aluminum sheets?

- The typical corrosion resistance of aluminum sheets is high, thanks to the natural formation of a thin layer of aluminum oxide on the surface, which acts as a protective barrier against corrosion.

- Q: I wish to purchase an 8' step ladder as well as a medium length extension ladder. What are the pros and cons of aluminum vs. fiberglass?

- The main advantage of fiberglass ladders is the reduction of electric shock from contact with electric wires. A disadvantage of fiberglass ladders is the tendency of fiberglass to crack. The inverse of this applies to aluminum. I bought a Little Giant ladder; it is a 300lb rated aluminum ladder with great stability and can function as a 12' step ladder and a 21' extension ladder. It cost me over $400, but after using it for over a year I would not buy any other kind regardless of the price. This is a solid, well-made ladder with great versatility. It also comes in smaller versions; I think the smallest one collapsed takes up only about 5 feet of space.

- Q: What is the corrosion resistance of aluminum sheets?

- Aluminum sheets have excellent corrosion resistance due to the formation of a protective oxide layer on their surface, which prevents further oxidation or corrosion.

- Q: Yesterday I picked up an 1988 performance bike. I bought it for the parts. It rode really good and now I'm deciding to keep it as is but I'm wondering if the bike is safe to ride. I've hear of aluminum horror stories and I'm assuming old aluminum isn't asnymore safe.Should I toss the frame and put the parts on a steel frame I have or ride it and not worry about it failing.

- 1988? Why do you believe it is aluminum? So far as I can recall, Performance didn't begin offering bicycles AT ALL until about 1992. Even then they had steel frames... their bikes were supplied by a Taiwanese company by the name of UEC who also made (and makes) KHS brand bikes. Regarding early aluminum failures, yes, there were many simply because factories were unfamiliar with the material and thought they could get away without the post treatment that a welded aluminum structure often requires. Another reason for aluminum frame failure was when a few factories attempted to bond aluminum tubes to lugs. This is also a problem with carbon fiber bikes. This is because the epoxy used degasses, or hardens and becomes crystallized. The now brittle epoxy cracks and results in catastrophic failure. This, in the factory's opinion, was not a warranty event. I'll tell you what. Grab a magnet off of your refrigerator and see if it sticks to the frame. if it does- even a tiny bit- then it is steel. If the frame is WELDED aluminum it should be retired since there is no way of telling whether the frame was properly post-treated. If the frame is BONDED then it should be retired because of the possibility of the epoxy fracturing.

Send your message to us

Aluminum Circle Aluminium Round Plate DC&CC

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords