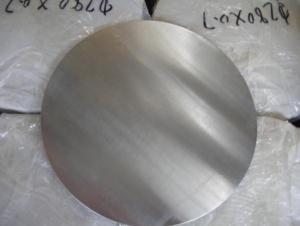

Aluminum D.C. Aluminium Circle

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 0.5 TONS

- Supply Capability:

- 1000Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1 Specifications of D.C. Aluminum Circle

|

Alloy |

AA1050, AA1060, AA1070, AA1100, AA3003, AA3005, AA3105, AA5052, AA8011 |

|

Temper: |

H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

|

Thickness: |

0.50-6.00mm |

|

Diameter: |

100mm- 1200mm |

|

Standard: |

GB/T3880-2006, ASTM, ISO, EU standard |

|

Special Specification is available on customer’s requirement | |

2 Usage/Applications of D.C. Aluminum Circle

Aluminum Circles have a wide variety of applications in cookware and kitchenware, including fried pans and pressure cooker. C.C. circle is excellent for spinning, deep-drawing (depth less than 10 cm), color or non-sticky painting with quite competitive price.

3 Packaging & Delivery of D.C. Aluminum Circle

Packaging: Seaworthy package, bubble plastic bag inside, anti-moisture paper wrapped outside, covered with cartons, on wooden pallets, in containers. Pallet weight: Max. 2.30 tons.

Shipment: the goods will be delivered in 40 days after getting the buyer's payment

4 Production Flow of D.C. Aluminum Circle

Melting-Rolling- Cutting- Annealing--Packing

- Q: This question asks for a list of typical metal alloys that are utilized in the production of cars.

- <p>Common alloys used in automobile manufacturing include steel alloys such as low carbon steel, high-strength steel, and stainless steel for body and frame construction. Aluminum alloys are also widely used for their lightweight properties, especially in engine components and body panels. Magnesium alloys are employed for parts requiring high strength-to-weight ratios. Additionally, cast iron is used for engine blocks and cylinder heads, while copper alloys are utilized in radiators and electrical wiring. Titanium alloys find use in high-performance or luxury vehicles for their exceptional strength and low weight.</p>

- Q: What are the safety standards for aluminum products used in everyday life?

- <p>Yes, there are safety standards for using aluminum products in daily life. These standards ensure the safety and quality of aluminum products. They cover aspects such as material composition, manufacturing processes, and product performance. The standards vary by country and product type, but they generally aim to prevent health risks associated with aluminum exposure, such as toxicity and contamination. Compliance with these standards is crucial to protect consumers and ensure the longevity and reliability of aluminum products.</p>

- Q: This question asks for a comparison of the pros and cons of using aluminum sheets as a roofing material.

- <p>Advantages of using aluminum sheets for roofing include their lightweight nature, which reduces structural load; corrosion resistance, making them suitable for coastal areas; and low maintenance requirements. They are also energy-efficient, reflecting heat and reducing cooling costs. Disadvantages include the potential for dents and damage from hail or heavy impacts, and they can be more expensive than some other roofing materials. Additionally, aluminum can be noisy during rain, and it may require more frequent replacement compared to some other materials due to its lighter gauge.</p>

- Q: Is it possible to utilize aluminum to enhance the durability and efficiency of batteries?

- <p>Yes, aluminum can be used to make batteries more durable and efficient. Aluminum's lightweight, high conductivity, and corrosion resistance make it a favorable material for battery components. In particular, aluminum-air batteries leverage aluminum's ability to provide a high energy density. Additionally, research is ongoing to improve lithium-ion batteries by using aluminum as a component in the anode, which can potentially increase energy storage capacity and lifespan. However, challenges such as aluminum's reactivity and the development of efficient recycling methods must be addressed for widespread adoption in battery technology.</p>

- Q: This question asks for everyday applications of aluminum foil.

- <p>Aluminum foil has various uses in daily life. It's commonly used for food storage, wrapping leftovers to keep them fresh. It's also used in cooking, such as covering dishes to retain moisture or creating packets for steaming foods. Aluminum foil is great for lining baking sheets to prevent sticking and making cleanup easier. It's also used for insulation, like wrapping pipes to reduce heat loss. Additionally, it's used for arts and crafts, shining surfaces, and even as a makeshift reflector for sunlight. Its versatility makes aluminum foil a staple in many households.</p>

- Q: Explain how the inclusion of copper impacts the characteristics of aluminum alloys.

- <p>The addition of copper to aluminum alloys significantly enhances their strength and hardness. Copper is one of the most effective alloying elements for aluminum, leading to the formation of a series of age-hardenable alloys known as the 2xxx series. These alloys, such as 2024, are characterized by their high strength-to-weight ratio and are often used in aerospace applications, structural components, and transportation equipment. The copper atoms in the aluminum matrix form precipitates that strengthen the alloy through a process called precipitation hardening. However, the addition of copper also reduces the alloy's ductility and corrosion resistance, necessitating careful control of the copper content and heat treatment processes to optimize the alloy's properties for specific applications.</p>

- Q: Is it possible to utilize recycled aluminum to manufacture new items?

- <p>Yes, recycled aluminum can be used to make new products. It is an environmentally friendly and cost-effective process. Recycling aluminum conserves energy, as it requires only 5% of the energy needed to produce new aluminum from raw materials. Recycled aluminum maintains its properties, making it suitable for various applications, including automotive parts, construction materials, and consumer goods. The process also reduces waste and greenhouse gas emissions, contributing to sustainability efforts.</p>

- Q: This question asks about the impact of aluminum on the aging process in living organisms.

- <p>Aluminum's effect on the aging process is a subject of ongoing research and debate. Some studies suggest that aluminum can accumulate in the body over time, potentially contributing to age-related diseases such as Alzheimer's. It is hypothesized that aluminum may interfere with cellular function, disrupt enzyme activity, and cause oxidative stress, which are all factors associated with aging. However, the exact mechanisms and the extent of aluminum's role in aging are not fully understood. It's important to note that the human body naturally has mechanisms to excrete aluminum, and the contribution of aluminum to aging is not conclusively proven. More research is needed to establish a clear link between aluminum exposure and the aging process.</p>

- Q: Is it safe and effective to use aluminum foil for wrapping food items in a refrigerator or freezer?

- <p>Yes, you can use aluminum foil to wrap food in a refrigerator or freezer. Aluminum foil is a good insulator and can help keep food fresh by preventing freezer burn and moisture loss. It also protects food from absorbing odors. However, it's important to ensure the foil is tightly wrapped around the food to maintain its effectiveness. Additionally, avoid using aluminum foil with acidic foods as it can react with them, potentially causing a metallic taste.</p>

- Q: What are the primary applications and benefits of aluminum in various industrial sectors?

- <p>Aluminum is extensively used in the industry due to its lightweight, high strength, and excellent corrosion resistance. It is a key material in the aerospace industry for aircraft construction to reduce weight and improve fuel efficiency. In the automotive sector, aluminum is used for engine parts and body panels to enhance fuel economy and performance. The construction industry utilizes aluminum for window frames, roofing, and structural components due to its durability and low maintenance. Aluminum is also prevalent in the packaging industry for food and beverage cans, and in electrical applications for wiring and transformers due to its high conductivity. Its recyclability makes it an environmentally friendly choice, further enhancing its industrial applications.</p>

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 1995 |

| Annual Output Value | Above US$50 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai Port |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aluminum D.C. Aluminium Circle

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 0.5 TONS

- Supply Capability:

- 1000Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords