Aluminum Bronze Color Coating Aluminium Coil AA3003 for Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Color Coating Aluminium Coil AA3003 for Decoration

characteristics | Application |

1) Super peeling strength | 1) Building exterior curtain walls |

2) Excellent surface flatness and smoothness | 2) Decoration and renovation additions for old buildings |

3) Superior weather, corrosion, pollutant resistance | 3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies |

4) Even coating, various colors | 4) Shop door decorations |

5) Fireproof, excellent heat and sound insulation | 5) Advertisement board display platforms and signboards |

6) Superior impact resistance | 6) Wallboards and ceilings for tunnels |

7) Lightweight and easy to process | 7) Industrial materials, materials for vehicles and boats |

2. Application of Color Coating Aluminium Coil AA3003 for Decoration

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels, column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Color Coating Aluminium Coil AA3003 for Decoration

• Our goods quality is top, the surface is smooth, and every steel coil

• No Joint, No Bends, no spots, no roller marks.

• MTC will be provided with goods, third part inspection is acceptable, for example, SGS, BV. Etc

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

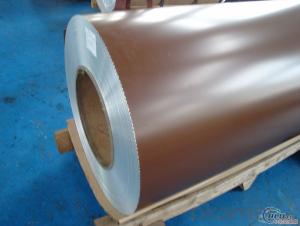

5. Image of Color Coating Aluminium Coil AA3003 for Decoration

6. Package and shipping of Color Coating Aluminium Coil AA3003 for Decoration

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are aluminum coils compatible with different welding methods?

- Different welding methods can be used with aluminum coils. Aluminum is a versatile metal that can be welded using techniques like gas tungsten arc welding (GTAW) and gas metal arc welding (GMAW). These methods are commonly used for welding aluminum coils because they produce high-quality welds. GTAW, also known as TIG welding, is particularly suitable for aluminum. It allows for precise control of heat input and produces excellent weld quality. TIG welding uses a non-consumable tungsten electrode and an inert gas like argon to protect the weld zone from contamination. GMAW, also known as MIG welding, is a faster process that uses a consumable wire electrode and a shielding gas to protect the weld pool. It is widely used in industrial applications due to its efficiency and ease of use. In addition to TIG and MIG welding, other methods like laser welding and friction stir welding can also be used for aluminum coils, depending on specific requirements. Proper preparation is crucial for successful welds. Cleaning and surface treatment of the aluminum coils are important to remove contaminants or oxide layers that could affect the welding process. Overall, different welding methods can be used with aluminum coils, and the choice depends on factors like desired weld quality, production requirements, and available skills and equipment.

- Q: How many atoms are there in a piece of aluminum foil, 7.3 inches in length and 12.0 inches in width, and 0.141 mm thick? According to this problem, aluminum foil is a flat-rolled product, rectangular in cross section, of thickness from 0.006(0.15mm) to 0.00025(0.006mm). The density of Al is 2.699 g/cm3.

- the nice and cozy button is Avogadro' sort that's 6.0226 x 10^23 atoms consistent with mole So if the cost of the Al roll is $2.fifty two for one lb Then proceed as follows: a million lb = 454 gms At Wt Al = 26.ninety 8 gms consistent with mole Moles of Al in a million lb = 454/26.ninety 8 = sixteen.80 two moles sort of atms of Al = sixteen.80 two x 6.0226 x 10^23 = a million.013 x 10^25 cost consistent with atom = $2.fifty two / a million.013 x 10^25 = $2.2847 x 10^-25 consistent with atom or 0.0000000000000000000000228 cents consistent with atom. BTW, you probably did no longer finished specify the situation - how thick is teh Al foil? In any journey Al atoms are enormously inexpensive. desire this helps

- Q: Are there any limitations to the coil weight of aluminum coils?

- The coil weight of aluminum coils is subject to limitations. The primary factor that restricts the coil weight is the capacity of the equipment used for handling and transporting the coils. Different machinery and materials handling systems have varying weight capacities. Exceeding these capacities can result in safety hazards and equipment damage. Furthermore, the size and dimensions of the coils also affect the maximum weight limit. Larger coils generally have a higher weight limit because they possess a larger surface area to distribute the load. Nonetheless, regardless of coil size, there is a practical limit to the weight that the machinery and equipment can bear. Additionally, the coil weight limit is influenced by the strength and integrity of the material used. Aluminum, being a lightweight material with a high strength-to-weight ratio, allows for larger coil weights compared to other materials. However, excessive weight may cause deformation or damage to the coil, impacting its quality and usability. It is essential to take these limitations into consideration and adhere to the manufacturer's recommendations and industry standards when determining the maximum coil weight. Following proper handling, storage, and transportation procedures is crucial to ensure the safety of personnel and the integrity of the aluminum coils.

- Q: How do aluminum coils contribute to architectural design flexibility?

- Architectural design flexibility is greatly enhanced by the unique properties and versatility of aluminum coils. Firstly, their lightweight nature simplifies handling and installation, in contrast to materials like steel or concrete. This attribute grants architects the freedom to explore more imaginative and innovative designs, unburdened by weight constraints. It also facilitates the construction of large and intricate structures, providing architects with greater design freedom. Secondly, aluminum coils offer an extensive array of surface finishes and colors. They can be painted, anodized, or coated with various materials, enabling architects to achieve desired aesthetic effects and harmonize the building's appearance with its surroundings or intended architectural style. This broad range of finishes allows architects to experiment with diverse visual effects, textures, and patterns, thereby enhancing overall design flexibility. Furthermore, aluminum coils possess exceptional corrosion resistance properties. This durability ensures that architectural elements made from aluminum coils can withstand harsh weather conditions, such as rain, snow, or UV radiation, without deteriorating over time. The extended lifespan and minimal maintenance requirements of aluminum coils make them an appealing choice for architects seeking sustainable and long-lasting design solutions. Moreover, aluminum coils can be easily shaped, bent, or formed into an assortment of profiles and dimensions. This malleability empowers architects to create custom architectural elements that meet specific design requirements, such as curved facades, intricate detailing, or irregular shapes. The ability to mold aluminum coils according to the architect's vision enables the realization of distinctive and unique designs that stand out in the architectural landscape. Lastly, aluminum coils are recyclable and environmentally friendly. By incorporating aluminum into architectural design, architects align themselves with sustainable practices, as aluminum can be recycled repeatedly without losing its properties. This aspect appeals to architects and clients who prioritize eco-friendly design solutions and seek to minimize their carbon footprint. In conclusion, aluminum coils significantly contribute to architectural design flexibility by offering lightweight construction, a wide range of surface finishes, excellent corrosion resistance, malleability, and recyclability. These characteristics empower architects to push the boundaries of design, create visually stunning structures, and deliver sustainable and enduring architectural solutions.

- Q: What certifications might be necessary for the production, sale, or use of aluminum coils?

- <p>Aluminum coils may require various certifications depending on their intended use and the standards set by different countries or industries. Common certifications include ISO 9001 for quality management systems, ISO 14001 for environmental management, and specific industry standards such as ASTM or EN standards for material properties and safety. For construction or automotive applications, additional certifications like CE marking in Europe or DOT certification in the US may be necessary. It's crucial to consult with industry standards and regulatory bodies to determine the exact certifications required for a specific application.</p>

- Q: Can aluminum coils be utilized as an insulating material?

- <p>Aluminum coils are not typically used for insulation. They are good conductors of heat and electricity, which makes them unsuitable for insulation purposes. Insulation materials should be poor conductors to prevent the flow of heat or electricity. Aluminum coils are more commonly used in applications where conductivity is desired, such as in electrical wiring or heat exchangers. For insulation, materials like fiberglass, mineral wool, or plastic foams are used because they resist heat flow effectively.</p>

- Q: Can aluminum coils be used in the production of beverage cans?

- Certainly, beverage cans can indeed be produced using aluminum coils. Aluminum is the preferred material for manufacturing beverage cans due to its lightweight nature, durability, and ability to maintain the taste and quality of the contents. Typically, aluminum coils are employed in the canning process as they can be readily molded into the desired can shape. These coils are rolled into sheets, which are subsequently cut and transformed into cans. Additionally, aluminum coils possess exceptional heat conductivity, enabling efficient cooling and faster production rates. All in all, aluminum coils play a crucial role in the production of beverage cans and are extensively utilized within the industry.

- Q: This question asks for methods to prevent rusting on aluminum coils during storage and transportation.

- <p>To prevent rusting on aluminum coils during storage and transportation, ensure that the coils are clean and dry before storage. Use a protective coating or wrapping to shield them from moisture and contaminants. Store the coils in a cool, dry place away from direct sunlight and corrosive substances. Avoid stacking them where they may come into contact with acidic materials. During transportation, secure the coils properly to prevent movement that could lead to scratches or damage. Use moisture-resistant covers to protect them from the elements. Regularly inspect the coils for signs of corrosion and address any issues promptly.</p>

- Q: Can a spring balance be used to accurately determine the weight of an aluminum coil?

- <p>Yes, you can use a spring balance to measure the weight of an aluminum coil, but the accuracy depends on the balance's specifications. Ensure the balance has a sufficient capacity to measure the coil's weight and is calibrated correctly. Keep in mind that spring balances are less precise than electronic scales, especially for heavy or sensitive measurements. For high accuracy, consider using an electronic scale designed for industrial use.</p>

- Q: Can aluminum coils be formed into different shapes?

- Yes, aluminum coils can be formed into different shapes. Aluminum is a highly malleable metal, which means it can easily be bent, shaped, and formed without breaking. This property makes it an ideal material for various applications where flexibility and versatility are required. Aluminum coils can be formed into different shapes using a variety of techniques, such as bending, rolling, stamping, extrusion, or even by using specialized machinery like a coil forming machine. These processes allow the aluminum coils to be transformed into a wide range of shapes, including sheets, plates, tubes, wires, or complex three-dimensional forms. The ability to form aluminum coils into different shapes makes it an excellent choice for industries such as construction, automotive, aerospace, and manufacturing, where customized parts and components are often needed.

Send your message to us

Aluminum Bronze Color Coating Aluminium Coil AA3003 for Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords