Wide Aluminum Roof Coil - Color Coating Aluminum Coil 3003 for Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Color Coating Aluminum Coil 3003 for Decoration

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

2. Application of Color Coating Aluminum Coil 3003 for Decoration

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Color Coating Aluminum Coil 3003 for Decoration

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

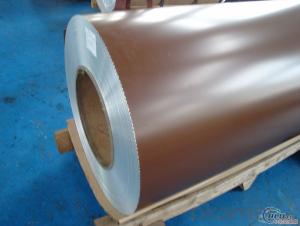

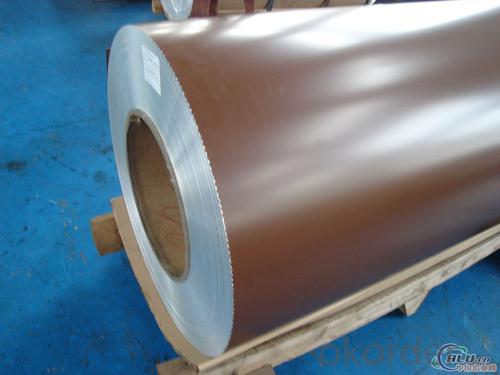

5. Image of Color Coating Aluminum Coil 3003 for Decoration

6. Package and shipping of Color Coating Aluminum Coil 3003 for Decoration

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What is the mass of 3.45 moles of Aluminum sulfate?Can u explain how?

- Aluminum sulfate is Al2S3, so you got two atoms of aluminum and three of oxygen. Hence the molar mass of aluminum sulfate is: 2X16 (two times molar mass of oxygen) + 3X32 (three times molar mass of sulfur). Keep in mind that the molar mass of an elements equals its mass number. We have 128 grams per mole or 128 pounds per lb-mol. Since you have 3.45 moles of Al2S3 you just have to do 3.45 times 128 = 441.6 grams

- Q: Can aluminum coils be used for food processing conveyor systems?

- Yes, aluminum coils can be used for food processing conveyor systems. Aluminum is a popular choice for conveyor systems in the food processing industry due to its various beneficial properties. Firstly, aluminum is a lightweight material, which makes it easier to install and transport. This is particularly important for conveyor systems that may require frequent reconfiguration or relocation. Additionally, aluminum has excellent corrosion resistance, which is crucial in food processing environments where exposure to moisture, chemicals, and food particles is common. Furthermore, aluminum is a hygienic material that is easy to clean and maintain, ensuring food safety standards are met. Lastly, aluminum coils can be easily formed and customized to fit specific conveyor system requirements, allowing for efficient and effective food processing operations. Therefore, aluminum coils are a suitable choice for food processing conveyor systems.

- Q: How to calculate the dosage of paint for aluminum coil coating? If the weight is 1 ton, the density 2.71 and the thickness 0.12mm, how much paint is needed?

- Coating surface area S*0.12(thickness)*ρ(density) / solid(paint solid)=actual paint consumption brush and roller paint: 100% spray paint: calculated value*70%

- Q: Are there any specific certifications or qualifications required for aluminum coil suppliers?

- Yes, there are specific certifications and qualifications that are important for aluminum coil suppliers. One of the key certifications for aluminum coil suppliers is the ISO 9001 certification, which ensures that the supplier has implemented a quality management system and meets the international standards for quality. This certification indicates that the supplier has effective quality control processes, consistent product performance, and customer satisfaction. Another important qualification for aluminum coil suppliers is the AS9100 certification, specifically for suppliers serving aerospace industries. This certification ensures that the supplier has met the quality management system requirements specific to the aerospace industry, including stringent quality control, traceability, and compliance with industry standards. Additionally, aluminum coil suppliers may also need to comply with specific industry standards such as the American Society for Testing and Materials (ASTM) standards or the European Union's REACH regulations for chemical substances. These standards ensure that the supplier's products meet the required specifications and are safe for use in various applications. Furthermore, some aluminum coil suppliers may possess specialized certifications or qualifications related to specific industries or applications. For example, suppliers serving the automotive industry may hold certifications such as the International Automotive Task Force (IATF) 16949 certification, which demonstrates their ability to meet the demanding requirements of automotive manufacturers. Overall, while specific certifications and qualifications may vary depending on the industry and application, aluminum coil suppliers should have certifications such as ISO 9001 and industry-specific certifications to ensure their products meet the required quality standards and comply with relevant regulations.

- Q: How do aluminum coils perform in saltwater environments?

- Aluminum coils perform exceptionally well in saltwater environments due to their natural resistance to corrosion. Unlike other metals, aluminum forms a protective oxide layer when exposed to saltwater, creating a barrier that prevents further corrosion. This oxide layer acts as a durable and long-lasting shield against the harsh effects of saltwater, ensuring the longevity and performance of aluminum coils in marine applications. Additionally, aluminum coils are lightweight and possess high thermal conductivity, making them popular choices for heat exchangers and condensers in saltwater-based cooling systems. Overall, aluminum coils are highly reliable and efficient in saltwater environments, making them a preferred choice for various marine applications.

- Q: What are the maximum operating temperatures for aluminum coils?

- The maximum operating temperatures for aluminum coils typically depend on the specific alloy used and the application they are being used in. However, in general, aluminum coils can withstand high temperatures without significant degradation or performance issues. For most common aluminum alloys, such as 3003 and 5052, the maximum operating temperature is around 300-400 degrees Fahrenheit (150-200 degrees Celsius). These temperatures are well within the range of most industrial and commercial applications, including HVAC systems, refrigeration units, and heat exchangers. There are also specialized aluminum alloys, such as 4004 and 4343, that are designed specifically for high-temperature applications. These alloys can withstand temperatures up to 550-650 degrees Fahrenheit (290-340 degrees Celsius) without significant loss of structural integrity or performance. It's worth noting that the maximum operating temperature may vary depending on factors such as the thickness of the coil, the heat transfer conditions, and the duration of exposure to high temperatures. Therefore, it is always advisable to consult the specific manufacturer's guidelines or conduct temperature tests to determine the safe operating limits for a particular aluminum coil in a specific application.

- Q: Are aluminum coils suitable for signage systems?

- Yes, aluminum coils are suitable for signage systems. Aluminum is a popular material choice for signage due to its durability, versatility, and lightweight nature. It is resistant to corrosion, which makes it suitable for outdoor signage that is exposed to various weather conditions. Aluminum coils can be easily molded into various shapes and sizes, allowing for flexibility in design. Additionally, aluminum can be painted or coated to achieve different finishes and colors, making it highly customizable and visually appealing for signage applications. Overall, the use of aluminum coils in signage systems ensures a long-lasting, low maintenance, and aesthetically pleasing solution.

- Q: What are the different surface treatments applied to aluminum coils?

- There are several different surface treatments that can be applied to aluminum coils to enhance their appearance, protect against corrosion, and improve their overall performance. Some of the most common surface treatments for aluminum coils include: 1. Anodizing: Anodizing is an electrochemical process that forms a protective oxide layer on the surface of the aluminum. This treatment enhances the corrosion resistance of the coils and provides a decorative finish. Anodized aluminum coils are available in a wide range of colors and finishes. 2. Painting: Painting is a surface treatment that involves applying a coating of paint to the aluminum coils. This treatment provides a decorative finish and can also enhance the corrosion resistance of the coils. Painted aluminum coils are commonly used in architectural applications where aesthetics are important. 3. Laminating: Laminating is a process that involves applying a thin layer of protective film to the surface of the aluminum coils. This treatment provides a protective barrier against scratches, abrasion, and UV radiation. Laminated aluminum coils are often used in applications where durability and weather resistance are important. 4. Polishing: Polishing is a mechanical process that involves buffing the surface of the aluminum coils to create a smooth and shiny finish. This treatment enhances the appearance of the coils and can also improve their corrosion resistance. Polished aluminum coils are commonly used in decorative applications where a high-end look is desired. 5. Brushing: Brushing is a mechanical process that involves creating a pattern of fine parallel lines on the surface of the aluminum coils. This treatment gives the coils a brushed or satin finish and can also help to hide imperfections and scratches. Brushed aluminum coils are often used in applications where a modern and sleek appearance is desired. Overall, the choice of surface treatment for aluminum coils depends on the specific application requirements and desired aesthetic. Each treatment offers unique benefits in terms of appearance, corrosion resistance, and durability, allowing manufacturers and designers to select the most suitable option for their needs.

- Q: This question asks for a brief explanation of the process involved in manufacturing aluminum coils.

- <p>To make aluminum coil, start with high-quality aluminum ingots. These are melted in a furnace and then poured into a casting machine to create a continuous cast strip. This strip is passed through a series of rollers to reduce its thickness and achieve the desired width and thickness. The rollers apply heat and pressure, gradually forming the aluminum into a coil. The coil is then cooled, often using water, and wound onto a mandrel for storage or further processing. Quality control checks are performed throughout the process to ensure the coil meets specific strength, thickness, and surface finish requirements. The final product is a tightly wound aluminum coil ready for use in various industries such as construction, automotive, and packaging.</p>

- Q: Inquiry about the feasibility of using aluminum coils for crafting jewelry or accessories.

- <p>Yes, you can use aluminum coils to make jewelry or accessories. Aluminum is lightweight, durable, and non-allergenic, making it a popular choice for crafting. It's easy to shape and work with, and it's also cost-effective compared to precious metals. You can create rings, bracelets, necklaces, and various other decorative items. Just ensure you use the right tools and safety precautions when working with metal, and finish your creations with appropriate polishing and sealing to enhance their appearance and longevity.</p>

Send your message to us

Wide Aluminum Roof Coil - Color Coating Aluminum Coil 3003 for Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords