Aluminum Alloy Sheet for Construction and Semi Trailer Wall Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

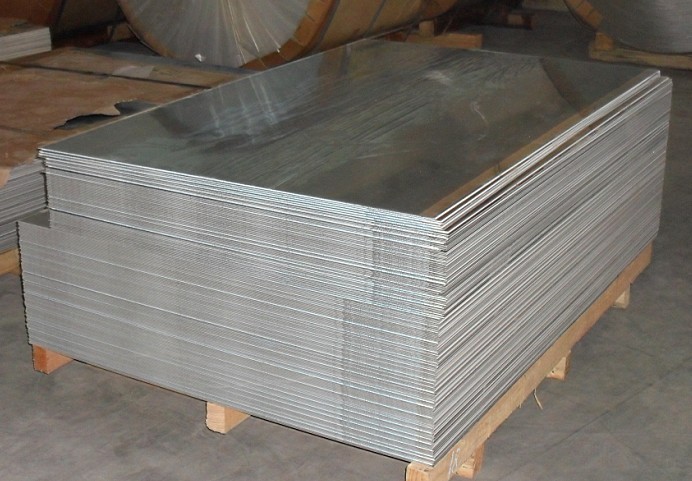

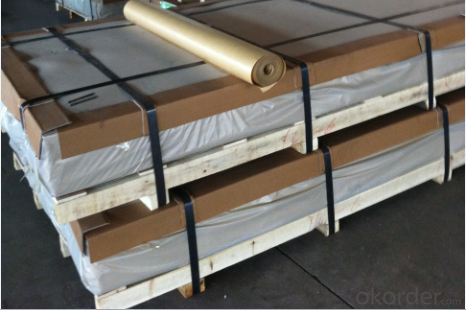

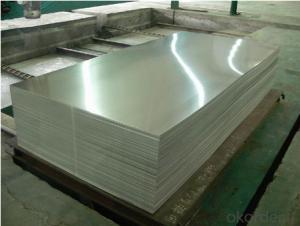

1.Structure of Product Description

Cold rolled aluminum sheet is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5000 series, 6000series, etc. The detailed grade are as follows: 1010, 1050,1060,1100, 2024, 3003, 3005, 3105, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

2. Main features of the product

a.Competitive price

c. Shortest service.

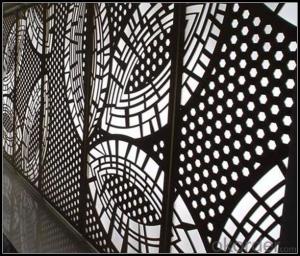

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm, 1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc

Where is your client from?

---Normally it is from Japan, USA, ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet, mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: How does aluminum sheet perform in high-pressure applications?

- Due to its inherent properties, aluminum sheet is exceptionally effective in high-pressure applications. Its impressive strength-to-weight ratio makes it a suitable option for withstanding high-pressure environments. Additionally, aluminum exhibits excellent corrosion resistance, a crucial feature when dealing with high-pressure conditions that involve exposure to moisture or aggressive chemicals. Moreover, aluminum sheet is highly malleable, allowing it to be shaped and formed into various configurations to meet the specific requirements of high-pressure applications. Its flexibility enables it to endure the forces and stresses exerted during high-pressure processes without compromising its structural integrity. Furthermore, aluminum demonstrates good thermal conductivity, which aids in dissipating heat generated by high-pressure systems. This characteristic helps prevent overheating and ensures efficient operation. However, it is important to consider that the performance of aluminum sheet in high-pressure applications can be influenced by factors such as sheet thickness and alloy composition. Therefore, it is crucial to carefully select the appropriate grade and thickness of aluminum sheet based on the specific requirements and operating conditions of the high-pressure application. In conclusion, aluminum sheet is a dependable and efficient choice for high-pressure applications due to its strength, corrosion resistance, malleability, thermal conductivity, and overall performance under demanding conditions.

- Q: This question asks for a list of aluminum sheet types suitable for exterior applications, indicating a need for knowledge on construction materials.

- <p>Aluminum sheets for exterior use come in various types, each with specific properties and applications. Some common types include: 1. Mill Finish Sheets: These have a natural aluminum finish and are corrosion resistant. 2. Anodized Aluminum Sheets: They offer enhanced durability and resistance to weathering. 3. Painted Aluminum Sheets: These are coated with a protective paint layer for improved aesthetics and weather resistance. 4. Embossed Aluminum Sheets: They provide a textured surface and are used for both aesthetic and functional purposes. 5. Perforated Aluminum Sheets: These have holes and are used for ventilation and light filtration. 6. Aluminum Composite Material (ACM) Sheets: These are lightweight and used for cladding due to their strength and low weight. Each type is chosen based on the specific requirements of the project, such as weather conditions, aesthetic preferences, and structural needs.</p>

- Q: Are aluminum sheets suitable for furniture manufacturing?

- Indeed, furniture manufacturing can make effective use of aluminum sheets. Aluminum, being a lightweight and versatile material, offers a multitude of advantages for the production of furniture. It possesses corrosion resistance, rendering it suitable for both indoor and outdoor furniture. Moreover, aluminum showcases a remarkable strength-to-weight ratio, facilitating the creation of robust and long-lasting furniture items. Additionally, aluminum proves to be easily malleable, as it can be cut, bent, and welded into various shapes and designs. Furthermore, aluminum can be treated with a diverse range of coatings or paints to enhance its visual appeal and safeguard it from damage. In summary, the strength, versatility, and aesthetic allure of aluminum sheets establish them as a viable alternative for furniture manufacturing.

- Q: Is it possible to use aluminum sheets in environments with high temperatures?

- <p>Yes, aluminum sheets can be used in high-temperature environments, but with certain considerations. Aluminum has a high melting point of around 660掳C (1220掳F), which allows it to withstand high temperatures. However, its mechanical properties can degrade over time when exposed to sustained high temperatures, especially above 200掳C (392掳F). For applications requiring long-term exposure to high temperatures, special heat-resistant aluminum alloys or coatings may be necessary to maintain structural integrity and performance. It's also important to consider the specific conditions and the maximum temperature the aluminum will be exposed to when determining its suitability for a high-temperature application.</p>

- Q: What are the semi hard ones? What are the alloys? What are the anti rust ones, such as 3003505210606061, 7075?

- 3003: board. Strip foil. Tensile plate, tube. Extrusion tube. Type. Rod. Rod. Cold bar, cold wire, rivet wire, forging, foil, heat sink material mainly used for processing requires good molding property, high corrosion resistance, good weldability and spare parts not only have these requirements, or performance need than the workpiece of 1*** alloy with high strength, such as transportation of liquid tank and tank, pressure tank, storage device, heat exchanger, chemical equipment, aircraft fuel tank, oil pipe, reflective panels, kitchen equipment, cylinder washing machine, rivet, welding wire.3003 aluminum alloy sheet, plate, tube drawing. The extruded tube housing partition, cap, pipe3004 plate, plate, pipe extrusion tube for tensile. As long as the whole aluminum cans cans, for more than 3003 alloy parts, chemical products production and storage device, sheet processing, building baffle, cable conduit, sewer, various lighting components.3004 aluminum alloy sheet, plate mainly used for housing partition, baffle, sewer, the roof of industrial plant5052 plate, plate, sheet, foil, drawing tube, cold processing bar, cold wire, rivet wire, this alloy has good shaping property, high corrosion resistance, weldability and fatigue strength, medium static strength, used in the manufacture of aircraft fuel tank, tubing, and vehicles, sheet metal parts, ship the instrument, street lamp and rivet wire and so on.

- Q: I'm working on a costume that's entirely made of cardboard (it's a giant robot), and I was wondering What's the best way to1 turn Soda cans into aluminum sheeting2: attach the aluminum everywhere on the robot3. Attach the aluminum to the aluminumThank you in advance.

- Why not heavy duty aluminum foil glued to cardboard? that would look a lot better than patched up pieces of aluminum from tin cans. How would you connect the chunks of aluminum together? and remove the label. Note that soda cans have a coating of plastic on the inside. I don't see any easy way to attach the bits of aluminum from tin cans together, and remove the painted on labels. It would look just like that, pieces of cans glued together. In stead of cardboard you could use foam board which is lighter and more rigid.

- Q: How does the purity of aluminum affect its properties as a sheet?

- The properties of aluminum as a sheet are significantly influenced by its purity. Increased levels of purity generally lead to improved mechanical properties, as well as enhanced thermal and electrical conductivity, and better resistance against corrosion. When aluminum possesses a high level of purity, meaning it contains minimal impurities, it becomes more malleable and ductile. This characteristic makes it easier to shape into thin sheets, rendering highly pure aluminum sheets more appropriate for applications requiring intricate shapes and designs. Moreover, the high electrical conductivity of pure aluminum makes it an exceptional choice for electrical applications, such as wiring and circuit boards. It enables efficient transmission of electricity while minimizing the risk of overheating. Additionally, the thermal conductivity of pure aluminum makes it an ideal option for heat transfer purposes. Aluminum sheets with a high level of purity can effectively dissipate heat, making them well-suited for applications like heat sinks and radiators. Furthermore, the corrosion resistance of aluminum increases with higher levels of purity. Pure aluminum forms a protective oxide layer on its surface, which serves to prevent corrosion and prolong the lifespan of aluminum sheets in various environments. In conclusion, the purity of aluminum directly impacts its properties as a sheet. Increased levels of purity enhance its mechanical properties, as well as its electrical and thermal conductivity. Additionally, it improves its resistance against corrosion, making it more versatile and suitable for a wide range of applications.

- Q: why intact aluminum sheet stop quicker than pectinate one in the magnetic field?

- while swinging in the magnetic field, intact aluminum sheets will formulate inner eddy current,that is the annular induced current.eddy current will transform the mechanical energy into heat energy, which makes the aluminum sheet stop quickly.but pectinate aluminum sheet can't formulate intact eddy current, so intact aluminum sheet stop quicker than pectinate one.

- Q: Alumina is the protective coating that covers aluminum when exposed to oxygen. It's actually corroded aluminum that prevents the aluminum from continuously corroding.What I didn't know until recently was that alumina is an electrical insulator. If that's the case why then isn't aluminum an insulator if one is trying to pass current along its surface?

- Aluminum is an efficient conductor of electricity. A usual fabric that is not conductive is glass but glass will habits heat. Wood isn't warmth conductive or an electricity conductor however has a low combustion factor. You probably have a specific utility you are watching for then you definitely'd better ask extra certain questions.

- Q: Can aluminum sheets be used for electrical enclosures?

- Certainly! Electrical enclosures can make use of aluminum sheets. Aluminum is a favored option for such enclosures owing to its impressive conductivity, resistance against corrosion, and lightweight characteristics. It serves as an effective electrical conductor, enabling efficient distribution of current within the enclosure. Furthermore, aluminum exhibits exceptional resistance to corrosion, rendering it appropriate for outdoor and challenging environments. Its lightweight nature also simplifies handling and installation processes. All in all, aluminum sheets prove themselves as dependable and frequently employed materials for electrical enclosures.

Send your message to us

Aluminum Alloy Sheet for Construction and Semi Trailer Wall Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords