Sheets Aluminum - Aluminium Stair Checker Plate 3003 H14 Thickness 2.5mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

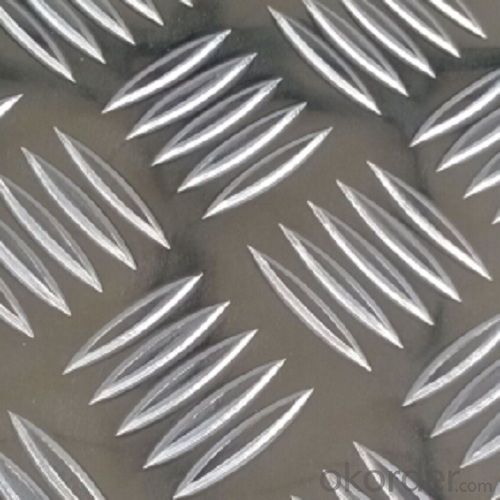

Aluminium Stair Checker Plate 3003 H14 Thickness 2.5mm

l Product Information:

1) Alloy: 1050, 1200, 1100,, 3003, 5052, 5754

2) Temper: H111, H112, O, H14, H24, H32

3) Thickness: 0.8mm to 10mm

4) Width: 100mm to 2300mm, Length: up to 11 Meter,

5) Patterns:Two bar, three bar, Five bar and diamond plate

6) Use: Refrigeration floor, Truck floor, flooring, stairs, indoor and outdoor decoration

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirement

Delivery detail: about 20 days from received oiginal L/C or advance payment

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

l CNBM World Wide

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: the amp setting when welding aluminum tig? and what color should the electrode feeder be bronze or chrome grey? u know the one u use with your hands

- Best electrodes to use for Aluminum welding is 1.5% lanthanum oxide (gold color code.). 2% zirconia (brown) or 2% thorium oxide (red) can also be used. Note that zirconia-doped electrodes should never be used for DC welding. A lot of welders like to quote offhand the rule 1 amp for every 0.001 inch of thickness. This applies to steel, stainless, and nickel alloys only. Due to the lower melting point, lower specific heat capacity, and higher thermal conductivity of of Al, this rule should NOT be used for Al! I recommend welding a test piece first with the same joint configuration and thickness of the part you intend to weld. Note that fillet welds require more current than butt welds or edge welds. Start out by using 2/3 amp per 0.001 of thickness, in other words, reduce the current of the above rule by about 30-40% . Make 3 test weld, then check to see if there's any visible penetration on the other side. If you don't see any through-pentration at all, increase the current by about 10-20 amps and test again.

- Q: It is a club aluminium dutch oven from the 50's. It is discolored on the interior and has baked on dirt on the exterior. The exterior has a textured surface which makes cleaning more difficult. I tried baking soda and water paste, but it did not budge it!

- Aluminum in that form for cooking really isn't safe anymore. Use it for a planter. The only really safe Aluminum cookware is Anodized (hardened on the outside). They have found that with he softer forms of Aluminum you are actually getting it in your food - they think this could be a link to Alzheimer's Disease.

- Q: I can't seem to find what uses or contains Aluminum Nitride. Help!

- Don't know where you looked, but this came up with very basic web search. Metallization methods are available to allow Aluminium nitride to be used in electronics applications similar to those of alumina and beryllium oxide. Among the applications of Aluminium nitride are opto-electronics, dielectric layers in optical storage media, electronic substrates, chip carriers where high thermal conductivity is essential, military applications, as a crucible to grow crystals of gallium arsenide, steel and semiconductor manufacturing. Epitaxially grown thin film crystalline aluminium nitride is also used for surface acoustic wave sensors (SAW's) deposited on silicon wafers because of the Aluminium nitride's piezoelectric properties. One application is an RF filter used in mobile phones called a thin film bulk acoustic resonator (FBAR). This is a MEMS device that uses aluminium nitride sandwiched between two metal layers.

- Q: I constructed a small hho generator for experimental purposes. I needed to add a cooling condenser to the unit because of a overheating problem. I was using a old heater core from a vehicle, soldered some joints to make some connections. the solution seemed to have eaten the solder I used, which was normal lead free solder used in water pipes. I was going to invest into a trans cooler core which is made of aluminum, but I need to know if the solution will eat up the aluminum. I also thought about using a condenser core from a broken window a/c, which is made of copper tubing. any advise would be very help full

- Figure out the Eknots using a chart. Cu -- Cu2+ = Enot of ? Al3+ --- Al = Enot of ? It needs to be positive to spontaneously react. I believe from memory that Al -- Al3+ is 1.3volts, so the reverse is negative. Meanwhile Cu is something under .5 volts, so it won't be enough to make the reaction work. This is further understood because aluminum requires a lot of energy to smelt from the oxide (which is the reverse reaction of Al3+ -- Al that you're talking about here) Secondly, do your homework man, it's REALLY obnoxious to add the why or why not and phrase everything exactly as your homework asks. Try to ask a question about the topic so you actually learn. For example, what are reduction potentials in terms of, for example, Cu --- Cu2+

- Q: On candle when candle flame is about 1.000 degrees celsius and melting point of aluminum is 660 degrees celsius.

- www.okorder /.. its doesnt burn burn u knw.it just becomes sorta britte.it becomes oxidised...u can got more infro there.try..i read it just now

- Q: What types of bonds can aluminum form: Covalent, Ionic and/or Metallic?Could you post the source, I've been looking for a while now :/

- I have considerable experience with adhesives of all types and for your project would suggest either 3M's Scotch Weld DP 420 or Loctite's Epoxy Weld bonding compound. Both are two part formulas and are good for bonding aluminum. Hope that helps.

- Q: Are the aluminum sheets suitable for manufacturing aircraft wings?

- Yes, aluminum sheets are suitable for manufacturing aircraft wings. Aluminum is a lightweight and strong material that offers excellent structural integrity, making it a popular choice in the aerospace industry. It also possesses good corrosion resistance and can be easily formed into complex shapes, further contributing to its suitability for aircraft wing manufacturing.

- Q: What are the fire-resistant properties of aluminum sheets?

- Aluminum sheets possess remarkable fire-resistant properties, making them an excellent choice for various applications where fire safety is a concern. The primary reason for their fire resistance is the unique oxide layer that forms naturally on the surface of the aluminum when exposed to oxygen. This layer acts as a protective barrier, preventing the metal from further oxidation and reducing the potential for combustion. The oxide layer on aluminum sheets is not only highly stable but also has a high melting point. This means that it can withstand high temperatures without melting or igniting, making it resistant to flames. Furthermore, the oxide layer is an effective thermal insulator, which helps to slow down heat transfer and prevent the spread of fire. Another advantage of aluminum sheets is their low flammability. Aluminum is a non-combustible material, meaning that it does not burn or support combustion. This property is particularly beneficial in situations where fire containment and prevention are crucial. Moreover, aluminum sheets have excellent heat dissipation capabilities. They quickly dissipate heat away from the source, minimizing the risk of overheating and potential fire hazards. This makes them suitable for various heat-intensive applications such as electrical enclosures, automotive parts, and industrial machinery. In summary, aluminum sheets exhibit outstanding fire-resistant properties due to the protective oxide layer, non-combustible nature, and efficient heat dissipation. These properties make them highly desirable for applications where fire safety is essential, providing peace of mind and protecting against potential fire incidents.

- Q: Can aluminum sheets be used for food packaging?

- Yes, aluminum sheets can be used for food packaging. Aluminum is a popular material choice for food packaging due to its unique properties. It is lightweight, flexible, and has excellent barrier properties, which means it can effectively protect food products from moisture, light, oxygen, and other external contaminants. Aluminum sheets are commonly used for packaging various food items such as beverages, canned goods, ready-to-eat meals, and snacks. Additionally, aluminum is also recyclable, making it an environmentally friendly choice for food packaging.

- Q: How is the thickness of aluminum sheets measured?

- The thickness of aluminum sheets is typically measured using a device called a micrometer or caliper. These instruments accurately measure the distance between two opposite sides of the sheet, providing an accurate measurement of its thickness.

Send your message to us

Sheets Aluminum - Aluminium Stair Checker Plate 3003 H14 Thickness 2.5mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords