Aluminum 711 Sheets Food Grade Aluminum Slab with Lower Price in Our Warehouse

- Loading Port:

- Shanghai

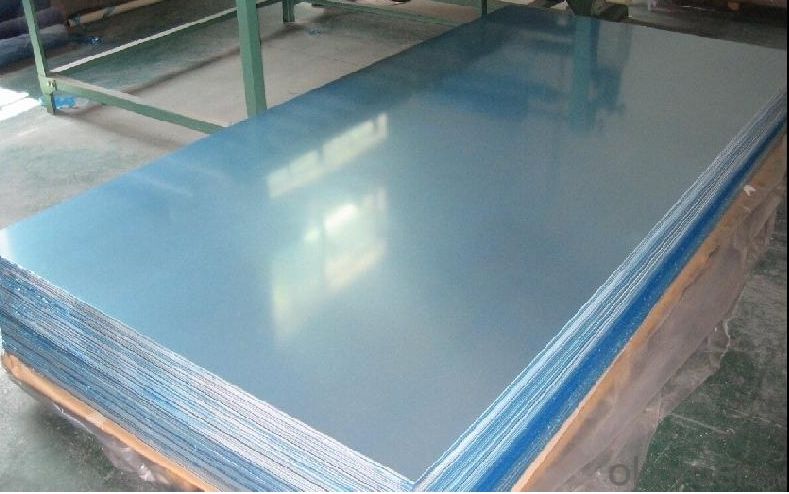

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 9 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Product Description

CNB, INTERNATIONAL CORPORATION'S Aluminum sheet is widely used in the field of industrial construction field, ETC. we also have cold rolled aluminum coil, checkered aluinium sheet, mirror finish aluminium coil,etc.

There are many different alloy nubmer: 3000SERIES,8000 series, etc. The detailed grade are as follows: 1010,1100, 2024, 3003, 5052,5754, 7075, 6063,8011, etc. The temper ARE AS FOLLOWS:H14, H24, F ,O, H1111,H114,etc.

2. Main features of the product

a. best-discount and the very competitiver price.

b. Shortest service.

3. Image.

4. Product detailed sizes:

1000mm*2000mm,1219mm*2438mm,500MM*500MM,1000*1000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 50mm to 2500mm, etc.

What is the length range:

---It is from 100mm to 6000mm, etc.

---Normally it is around 14 tons/each size.

How many tons did you export in one year?

Where is your client from?

---Normally it Arabia, BANGLADESH,PAKISTAN,FIJI, England,Turkey,etc.

What is your mainly products?

---Normally they are aluminum sheet,big-5-bar aluminium checkered sheet,small-,mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: How do you store aluminum sheets?

- Aluminum sheets should be stored in a dry and well-ventilated area, preferably indoors, to prevent corrosion. They should be stacked horizontally on a flat surface, with a protective covering such as plastic or cardboard between each sheet to avoid scratches. Additionally, it is advisable to separate different gauges or alloys to avoid galvanic corrosion. Regular inspection and maintenance are essential to ensure their longevity.

- Q: Are aluminum sheets prone to warping?

- Under certain conditions, aluminum sheets may be susceptible to warping. Unlike steel, aluminum is a relatively soft metal, making it more prone to bending or distorting. However, the extent of warping in aluminum sheets depends on various factors, including sheet thickness, alloy composition, temperature exposure, and applied stress levels. Thinner aluminum sheets have less structural integrity, making them more prone to warping. Conversely, thicker sheets are more resistant to warping due to their increased rigidity. The specific alloy composition of the aluminum sheet also affects its susceptibility to warping. Warping can occur due to temperature fluctuations. High temperatures cause aluminum to expand, and without proper support, it may bend or warp. Similarly, rapid cooling causes contraction, leading to warping. The level of stress applied to aluminum sheets can contribute to warping. Excessive bending, pressure, or unevenly distributed loads can deform the sheet. To minimize warping, it is crucial to handle aluminum sheets carefully, provide adequate support during temperature changes, and avoid applying excessive stress. Additionally, using thicker sheets or selecting alloys with higher tensile strength helps reduce the risk of warping.

- Q: Can you make tank armor using Aluminium, Polymers, Styrofoam, Explosive Reactive Armor to stop NATO DP rounds and/or HEAT rounds maybe RPG-7?

- Aluminium has a strength up to 800 N/mm2 (for its best Al-based alloys) while steels can go much higher... about 1400 N/mm2 if I recall well. The problem with aluminium is that is prompt to fatigue break which is not good with something vibrating like a rolling tank armor. Polymers are not strong enough unless you use composite materials, for ex. fibre glass or even better - carbon fibre reinforced. The problem is still that unlike steel, the strength is exceptionally high... in one direction - so pray for the impact to be mostly from this direction.

- Q: I recently had a new bridge plate and knobs made from aluminum for my guitar. They are bare uncoated aluminum. How would I go about protecting the parts from oxidation and corrosion? I just worry about the bridge plate because of sweat from playing my guitar near the bridge. There are no local places to get the parts chromed or anodized unfortunately.

- in case you have coverage or can cope with to pay for to - flow see an Ear nostril Throat wellbeing care professional (additionally spoke of as otolaryngologist or ENT for short) it incredibly is the main secure and smartest element to do. maximum probable he will prescribe an ear flush for you that works o.k.. additionally, listening to in triplicate may well be a symptom of nerve inflammtion or different ailment which will properly be examined for quite truthfully by potential of a doctor. Odds are this is not something, yet extra effective risk-free than sorry.

- Q: What are the special coatings or treatments available for enhancing the properties of aluminum sheets?

- <p>Yes, there are several special coatings and treatments that can be applied to aluminum sheets to enhance their properties. These include anodizing, which creates a protective oxide layer, powder coating for a durable and colorful finish, and thermal spraying for improved wear resistance. Other treatments involve chemical conversion coatings, such as chromate conversion, which provides corrosion resistance, and various types of plating like electroplating or hot-dip galvanizing for added strength and protection. These treatments can significantly improve the appearance, durability, and performance of aluminum sheets in various applications.</p>

- Q: Are there any health risks associated with using aluminum sheets?

- Yes, there are potential health risks associated with using aluminum sheets. Aluminum is a neurotoxic metal that can accumulate in the body over time. Prolonged exposure to high levels of aluminum has been linked to several health issues, including respiratory problems, bone disorders, and neurodegenerative diseases such as Alzheimer's. Additionally, certain studies suggest a possible link between aluminum exposure and an increased risk of developing breast cancer. It is important to take precautions when working with aluminum sheets and minimize exposure to the metal.

- Q: What are the different surface treatments for aluminum sheets to improve corrosion resistance?

- Some of the different surface treatments for aluminum sheets to improve corrosion resistance include anodizing, chromate conversion coating, powder coating, and painting.

- Q: I have a friend to purchase a number of aluminum, used to make computer cooling plate. He asked me to help with the supplier, can I look at the Internet, there are many kinds of aluminum, would like to ask: what kind of computer cooling plate used to do a bit better? What are the suitable suppliers in Guangdong?

- Computer cooling aluminum plate, mainly using 6063 T5 high quality aluminum and high quality copper, they are mainly used to make aluminum extrusion fin. 6063 T5 high-quality aluminum material can reach more than 98%, and its heat conduction ability, small density, cheap price, so get the love of major manufacturers.At present, the common aluminum extrusion fins are made of copper and aluminum alloy, and each of the two has its own advantages and disadvantages.

- Q: We just bought a house with aluminum wiring and we knew about it in the inspection report, but everyone kept telling us it's no big deal. There was so much going on and I didn't look into it myself and now I just surfed the web on it and I am filled with anxiety! Please help! Did we make a huge mistake? How common are the dangers? Also, my insurance company didn't ask me about wiring, but some sites said that they don't cover aluminum wiring. Should I ask them? I am so overwhelmed and scared. I do not want a fire for my family!

- Lots of great answers here. IF and I do mean IF your aluminum wiring was installed and maintained properly, there will be no problem. However, if someone has replaced any device designed for aluminum with one for copper, you WILL have a problem. My advice...call a GOOD electrical contractor for an independent inspection. Make sure he knows that his company will NOT be the one to make corrections beforehand. This insures that he will give you an honest inspection and not try to use the moment for a sales pitch. After the inspection, hire him to do the work. A bit devious, but the plan is sound.

- Q: I am following a recipe for braised ribs that calls for wrapping the ribs in heavy duty aluminum foil. I don't have heavy duty, so can regular aluminum foil be used as a replacement?

- You can use regular aluminum foil in place of heavy duty foil, but will have use 2-3 layers of the regular foil. Also be careful when wrapping the ribs in the foil that bones do not tear the foil. Heavy duty foil is also wider than regular foil so you may have to join 2 piece of regular foil together. Cut off two-there layers (4-6 pieces) of regular aluminum foil to the length you need, line the layers next to each other, then take the double or triple layers and line them up, fold over the edges 3-4 times to make a seal. The folds need only be a 1/4 - 1/2 inch.

Send your message to us

Aluminum 711 Sheets Food Grade Aluminum Slab with Lower Price in Our Warehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 9 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords