Aluminum Full Skin Sheets - Aluminium Coil with Best Stocks Price in Our Warehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Product Description

cold drawn and cold rolled aluminum sheet is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series,6000 series,7000series, 8000 series, etc. The detailed grade are as follows: 1050, 1100,1060,2024, 3003, 3105, 5052,5754,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,F,etc.

2. Main features of the product

a.Competitive price

c. Shortest service.

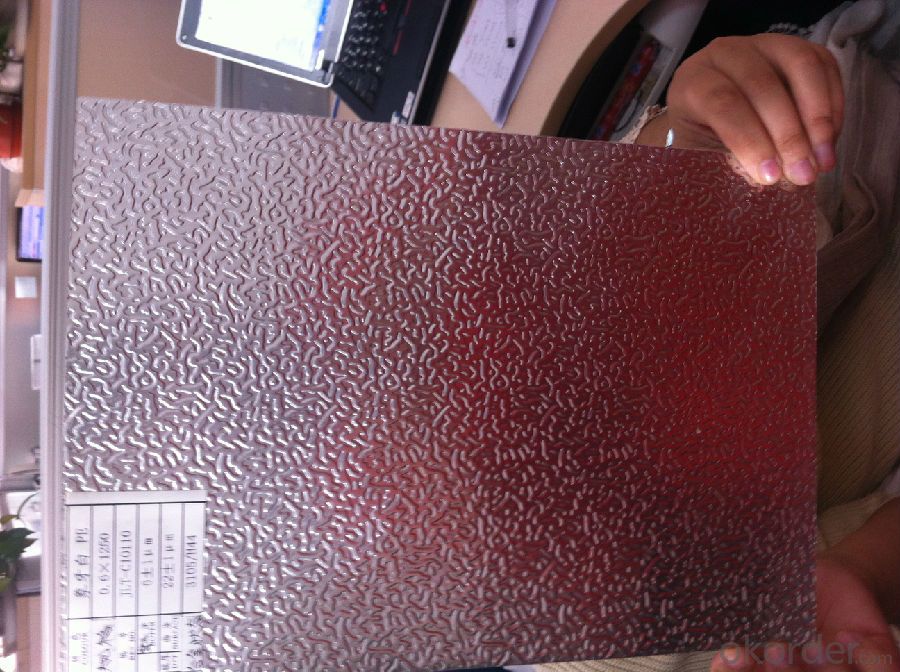

3. Image.

4. Product detailed sizes:

1220mm*2440mm,1219mm*2438mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 300mm to 2500mm, etc.

What is the length range:

---It is from 500mm to 6000mm, etc.

---Normally it is around 2 tons/each size.

How many tons did you export in one year?

Where is your client from?

---Normally it is from bangladesh, fiji, SRI LANKA,uae,Saudi Arabia,

What is your mainly products?

---Normally they are aluminum sheet,big-5-bar aluminium checkered sheet,small-5-bar aluminium checkered sheet,mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: I've created a sculpture out of aluminum foil, but it's pretty flimsy. What can I paint or cover it with that would harden and support it? I was thinking a resin or something, but I have no experience with resins or epoxies... Any suggestions?

- You have to make it thick, the aluminum IS weak material. or use harder raw material.

- Q: Can the export quality of China's aluminum plate meet the requirement of ASTM B 209? Is this requirement for our country? Master the exhibitions, O (a _ U) O thank you

- This is not quite clear, you Baidu once "work standard net" in "work standard net" check to know!

- Q: Are the aluminum sheets suitable for manufacturing architectural ceiling panels?

- Indeed, architectural ceiling panels can be manufactured using aluminum sheets. Aluminum possesses durability, a lightweight nature, and corrosion resistance, rendering it a perfect material for architectural purposes. It can be effortlessly shaped and molded into diverse panel designs and sizes, granting flexibility in crafting distinctive ceiling designs. Furthermore, aluminum sheets come in various finishes and colors, enabling customization to satisfy specific design needs. In summary, aluminum sheets offer a cost-effective and visually delightful solution for the production of architectural ceiling panels.

- Q: Can aluminum sheets be perforated for ventilation purposes?

- Yes, aluminum sheets can be perforated for ventilation purposes. Perforating aluminum sheets allows for the passage of air, making them suitable for ventilation applications in various industries.

- Q: Can aluminum sheets be used in automotive applications?

- Yes, aluminum sheets can be used in automotive applications. Aluminum is lightweight, corrosion-resistant, and has good strength-to-weight ratio, making it an ideal material for manufacturing automotive components such as body panels, engine parts, and structural components.

- Q: I am looking at buying a used 1983-84 Eldorado but have read some things about the reliability of the aluminum engine. Any thoughts? Thanks.

- 1984 Cadillac Eldorado

- Q: Can aluminum sheets be used in construction?

- Yes, aluminum sheets can be used in construction. They are commonly used for roofing, siding, and structural applications due to their lightweight, corrosion-resistant, and durable properties.

- Q: This question asks for a list of various types of aluminum profiles that are typically used in conjunction with aluminum sheets.

- <p>Aluminum profiles are extruded shapes commonly used with aluminum sheets for various applications. The different types include: 1. Angle profiles, which are used for corners and edges. 2. Channel profiles, suitable for creating channels or frames. 3. T-slot profiles, ideal for modular systems requiring adjustable components. 4. U-channel profiles, used for covering edges and creating frames. 5. H-profiles, often used in structural applications. 6. Flat bar profiles, used for simple straight edges. 7. Round and square tube profiles, used for structural support and design elements. 8. Special profiles, which are custom-made for specific applications. These profiles are chosen based on the structural needs and design requirements of the project.</p>

- Q: I am trying to find a BRUSH ON type glue to adhere aluminium foil to a plastic model. scotch super 77 works great but dries way to fast and blows small pieces all over. white glue just dont work and superglue eats the plastic. I could use some help

- Gluing Aluminum

- Q: What are the different methods of surface texturing aluminum sheets?

- Aluminum sheets can be textured in various ways, each with its own advantages and applications. 1. Mechanical Texturing involves using mechanical tools or processes, like brushing, sanding, or embossing, to create patterns or textures on the surface of aluminum sheets. This method is commonly used to achieve a matte or brushed finish, enhancing the appearance and concealing imperfections. 2. Chemical Texturing involves using chemicals to etch the surface of aluminum sheets and create unique patterns or textures. Acid etching, for example, selectively dissolves the surface to create a textured effect. This method is often employed to improve adhesive properties, making the sheets suitable for bonding or coating applications. 3. Anodizing is an electrochemical process that forms a controlled oxide layer on the surface of aluminum sheets. It can create various textures, ranging from smooth and glossy to rough and matte. Anodizing not only enhances the appearance but also improves corrosion resistance and durability. It is commonly used in architecture, consumer products, and automotive parts. 4. Laser Texturing utilizes laser technology to create precise and intricate patterns or textures on aluminum sheets. Laser beams can be accurately controlled to remove material or modify the surface, allowing for highly customized and detailed textures. This method is often utilized in high-end applications, such as jewelry, signage, or interior design. Each texturing method offers unique benefits and is suitable for different applications. The choice depends on factors such as desired texture, durability requirements, aesthetic preferences, and intended use of the aluminum sheets.

Send your message to us

Aluminum Full Skin Sheets - Aluminium Coil with Best Stocks Price in Our Warehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords