Aluminium Sheet 2024 5052 5083 6061 7075 Price Per Kg

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications

Grade

| 1000 Series: 1050 1060 1070 1100 1200 1235 etc. 3000 Series: 3003 3004 3005 3104 3105 3A21 etc. 5000 Series: 5005 5052 5083 5086 5154 5182 5251 5754 etc. 6000 Series: 6061 6063 6082 6A02 etc. 8000 Series: 8006 8011 8079 etc. |

Thickness | 0.2~320mm |

Width | <2800mm< span=""> |

Color | Metallic, Solid, RAL or by customer requirements |

Coating paint: | PVDF(Polyvinylidene Fluoride), PE(Polyester ) |

Coating thickness | as per customer’s request |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | Polyester18~27micron(EN ISO-2360:1995) PVDF27 ~35micron(EN ISO-2360:1995) |

Coating hardness | 2H |

Protective film | PVC film, Colorless transparent or White-black |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

Temper | H16, H18, H24, H26, H26 |

Certification | ISO9001:2000, CE, SGS |

Payment | L/C ,T/T |

Brief Introduction for Cold Rolled Steel Coil

Cold Rolled Steel Coil is steel that has been worked below its recrystallization temperature by passing it between a pair of rollers. Recrystallization temperature is the temperature at which grains in the lattice structure of the metal have been rearranged, leaving it free of strain and deformations. Cold Rolled Steel Coil is pre-treated before being cold rolled with a process known as pickling, which uses strong acids to remove scale and other impurities. The Cold Rolled Steel Coil is then passed through rollers to reduce its thickness. Most cold rolling takes place in multiple passes and as the size of the Cold Rolled Steel Coil is further reduced, its strength and hardness both increase, but its ductility decreases. After cold rolling, heating the metal up in a process known as annealing can restore some of its ductility. The final Cold Rolled Steel Coil may be manufactured in the form of sheets, strips, bars, or other forms.

FAQ

1. How can I get some samples?

We are honored to offer you samples. New clients are expected to pay for the courier cost. The samples are free for you.

2 Do you have any certificates?

Our products passed inspection of SGS, FDA, and CE Quality is priority! Every worker keeps the QC from the very beginning to the very end, Quality control department especially responsible for quality checking in each process.

3 Can your factory print or emboss my logo on the goods?

Yes, we can print or emboss the logo on the goods or their packing box.

4 What information should I let you know if I want to get a quotation?

1) The specification of products (length x width x thickness);

2) The temper and alloy.

3) The final product you will use to be made

4 It will be better if you can show us the pictures or design sketch. Samples will be best for clarifying. If not, we will recommend relevant products with details for reference.We usually produce goods based on customers

Samples or based on customers’ picture, logo, sizes etc.

Our Services

1. Reasonable production arrangement to make delivery very fast;

2. We are able to provide leading tolerances, metallurgical assistance, quick and reliable delivery, samples for new products, etc.

3. We have the strong capability to meet your particular requirement for the products.

4.To guarantee the quality of the products we can meet most of the standards all over the world.

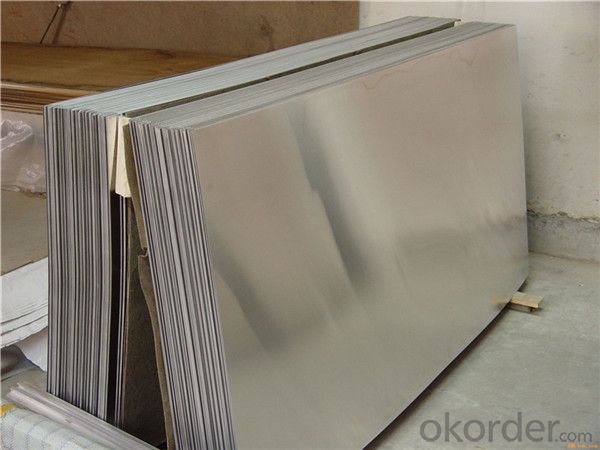

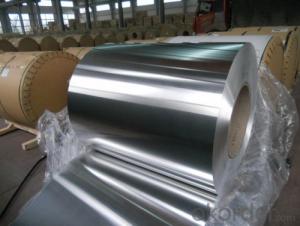

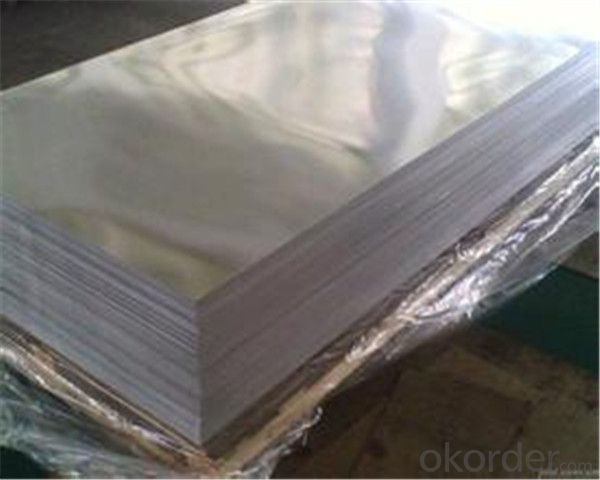

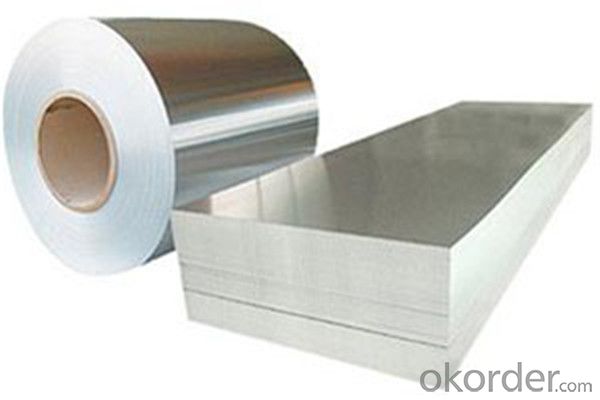

Photos of products

- Q: How do you prevent surface marring of aluminum sheets during handling?

- To prevent any damage to the surface of aluminum sheets when handling them, there are several steps that can be taken: 1. Use clean gloves or finger cots: It is important to avoid direct contact between bare hands and the aluminum sheets, as hands can contain oils, dirt, or other contaminants that may leave marks on the surface. Wearing clean gloves or finger cots acts as a barrier and prevents any transfer of substances onto the sheets. 2. Utilize protective packaging: Before handling the sheets, consider using protective packaging such as foam or plastic sheets to cover the surface. This provides an additional layer of protection against scratches or abrasions during transportation or storage. 3. Implement proper storage and handling techniques: Store the aluminum sheets in a clean and dry environment, away from any abrasive materials or surfaces. When moving or handling the sheets, ensure they are lifted or supported evenly to prevent bending or distortion that could lead to surface damage. Using appropriate lifting equipment, such as suction cups or clamps, helps distribute the weight evenly and minimizes the risk of harm. 4. Regularly clean the surface: Clean the aluminum sheets on a regular basis using a mild detergent or cleaning solution specifically designed for aluminum. This removes any dirt, grime, or other substances that could potentially cause surface damage. Ensure soft, non-abrasive cleaning tools like microfiber cloths or sponges are used to avoid scratching. 5. Implement quality control measures: Establish quality control measures during the handling process to identify any potential causes of surface damage. Conduct regular inspections to check for signs of harm or defects. Properly train employees involved in the handling process to minimize the risk of surface damage. By following these preventive measures, the chances of surface damage to aluminum sheets during handling are significantly reduced, ensuring they remain in pristine condition and maintain their quality.

- Q: Are aluminum sheets suitable for chemical reactors?

- Depending on the specific application and conditions, aluminum sheets can be suitable for chemical reactors. Aluminum is known for its excellent corrosion resistance, particularly when exposed to air or water, thanks to the formation of a protective oxide layer. This quality makes it appropriate for many chemical reactions involving non-aggressive substances. However, it's important to note that aluminum may not be suitable for reactors that handle highly acidic or alkaline solutions. Such solutions can corrode the oxide layer and cause the metal to degrade. Furthermore, aluminum may react with certain chemicals like strong oxidizers, halogens, or strong bases, which can compromise the integrity of the reactor. In situations where aluminum is used in chemical reactors, it is common to apply protective coatings or linings to enhance its resistance to corrosion and chemical reactions. These coatings serve as an additional barrier between the aluminum and the reactants, ensuring safe and effective operation. Ultimately, the appropriateness of using aluminum sheets for chemical reactors depends on the specific chemical reactions, operating conditions, and the required level of corrosion resistance. It is always advisable to consult with experts and consider material compatibility before selecting aluminum for such applications.

- Q: Is it possible to utilize aluminum sheets in the construction of furniture?

- <p>Yes, aluminum sheets can be used for furniture. They are lightweight, durable, and resistant to corrosion, making them suitable for various types of furniture such as outdoor furniture, tables, chairs, and shelving. Aluminum's strength and flexibility allow for creative designs and easy maintenance. Additionally, it is a sustainable material that can be recycled, contributing to environmental sustainability.</p>

- Q: Right now I have got some problems on how to machine high purity aluminium machinery,are thery any suggestions to promote for this kind of consecutive issue?

- Aluminum okorder is a soft, silvery-white metal. In high-purity aluminum nearly all impurities have been removed. It is 99.99 percent pure and is machined like other grades of aluminum. To process aluminum for various applications, the manufacturer heats the aluminum in a smelter and then forms it into ingots (large blocks) or billets (log-shaped rods). Using rolling mills, workers machine ingots into aluminum plates, sheets or foils. Dies machine ingots or billets into extrusions or forgings.

- Q: i need to know these things please....can aluminium withstand the forces of being in a cargo hold on a air freight, can it withstand extreme temps and to what extent an is it microwavable?? please help me

- No metals are microwavable, they will ruin any microwave oven by producing sparks. Even ceramic plates with a little metallic paint eg of silver will spark. Aluminium on its own has little strength but when mixed with small amounts of eg copper or manganese it aquires great strength while remaining light. In addition it has the advantage of being very resistant to oxidation and corrosion. It is certainly used extensively in aircraft construction. Due to being non toxic it used to make cans for beers, soft drinks (sodas) etc However it doesn't stand up well to high temperatures, its melting point is just at 660 degrees celsius, by comparison for iron it is 1540 and tungsten 3420.

- Q: Can aluminum sheet be bent or formed into different shapes?

- Indeed, aluminum sheet possesses the capacity to be effortlessly bent or molded into diverse forms. As a remarkably ductile metal, aluminum can be bent, shaped, or molded without any risk of cracking or fracturing. This characteristic renders it a perfect selection for a wide array of applications where adaptability and customization are essential. Multiple techniques, including the utilization of a brake press, roll forming, or specialized bending tools, can be employed to bend aluminum sheets. The degree of bendability may vary based on the thickness and grade of the aluminum sheet. Nevertheless, in general, aluminum is renowned for its exceptional malleability and aptitude to assume various configurations.

- Q: What are the different methods of surface cleaning for aluminum sheets?

- There are several methods of surface cleaning for aluminum sheets, including mechanical cleaning such as sanding or grinding, chemical cleaning using solvents or acidic solutions, and electrolytic cleaning which involves using an electric current to remove contaminants. Additionally, ultrasonic cleaning and steam cleaning are also commonly used methods to clean aluminum surfaces.

- Q: What are the methods used to treat the surface of aluminum sheets to improve their properties or appearance?

- <p>Surface treatment of aluminum sheets involves various processes to enhance their properties or appearance. These include anodizing, which creates a protective oxide layer; painting, which provides a decorative and protective coating; powder coating, a durable and corrosion-resistant method; polishing, which gives a shiny finish; and etching, which creates decorative patterns. Other treatments include chemical conversion coatings, such as chromate and phosphate, for corrosion resistance, and thermal spraying for wear resistance. Each method serves a specific purpose, from improving durability to aesthetic enhancement.</p>

- Q: What types of aluminum sheets are recommended for outdoor applications due to their durability and resistance to weather conditions?

- <p>Yes, there are specific types of aluminum sheets designed for outdoor use. Marine-grade aluminum sheets, such as 5083 or 5086 alloys, are highly resistant to corrosion and are ideal for marine applications. Aluminum sheets with a protective coating, like anodized aluminum or those with a fluoropolymer finish, offer excellent weather resistance and durability. Additionally, aluminum sheets with a mill finish or those coated with a clear coating can also be suitable for outdoor use due to their resistance to UV rays and ability to withstand temperature fluctuations.</p>

- Q: What is the typical bend radius for aluminum sheets?

- The typical bend radius for aluminum sheets depends on various factors, such as the alloy, thickness, and temper of the sheet. However, a general guideline for the minimum bend radius for aluminum sheets is typically around 1 to 1.5 times the material thickness. For example, if you have a 1mm thick aluminum sheet, the minimum bend radius would be around 1 to 1.5mm. It is important to note that this is just a general guideline, and the specific bend radius may vary depending on the specific application and requirements. It is advisable to consult with a professional or reference material specifications for precise bend radius recommendations for a specific aluminum sheet.

Send your message to us

Aluminium Sheet 2024 5052 5083 6061 7075 Price Per Kg

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords