2A12 5052 5083 6061 6083 7075 Aluminum Sheet Price per kg

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

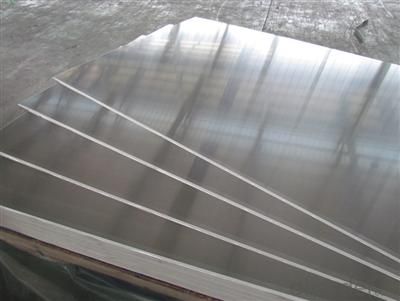

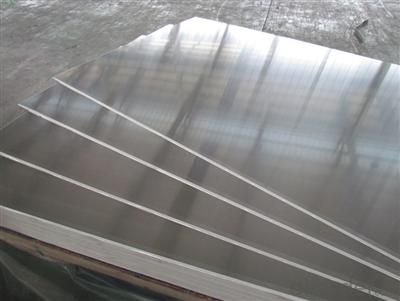

Aluminum sheet specifications:

1) Alloy : 1A99,2A12,2024,2219,2618,2A50,2A70,5A06,5083,6082,7075,7050, 7A85,7020 etc

2) Temper: O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc

3) Thickness: 0.1mm to 350mm

4) Width:20mm to 3300mm

5)Length: Accord to customer's requirements.

Reliable Quality,Reasonable Price and Good Service.

Any email will be replied with 24 hours. Thanks for your time!

6061 Aluminum plate/ aluminum thin sheet/ aluminum coil/ aluminum pipe application

The main alloy elements of 6061 alloy are Mg and Si and they form into Mg2Si. If it contains a certain amount of Mn and Cr, the bad effect of the iron can be neutralized. Sometimes you could also add a small amount of Cu and Zn to improve the strength of the alloy without decreasing its corrosion resistance obviously. Conductive material also contains a small amount of Cu which helps to counteract the bad effect of Ti and Fe on the electrical conductivity. In order to improve its cutting property, you could also add Pb and Bi. The alloy will has artificial aging hardening function when Mg2Si Solid soluble in aluminum.

6061-T651 is the main alloy elements of 6061 alloy. It is high quality aluminum products which are produced by heat treatment of pretensioning technique. Although its intensity cannot compare with 2XXX and 7XXX series, it has more magnesium and silicon alloy properties. It also has excellent process ability, good welding characteristics and plating properties, good corrosion resistance and high toughness. When you process it, there will be no deformation exist and no defects occur because of its dense material. What’s more, it is easy being polished and coloring the film and it has very good oxidation effect.

Representative applications include aerospace fixing device, electric appliance fixing device, communication field, automatic machinery parts, precision machining, mold manufacturing, electronics and precision instruments, SMT, PC board solder vehicles and so on.

Packaging & Delivery

| Packaging Details: | Bulk packaging for 6061 aluminum of do as you required |

| Delivery Detail: | 30 days for 6061 aluminum after you confirm the order |

- Q: What are the different methods of surface coating aluminum sheets?

- There are several methods of surface coating aluminum sheets, including anodizing, powder coating, paint coating, and electroplating.

- Q: Can aluminum sheet be used for aerospace structural components?

- Certainly, aerospace structural components can indeed utilize aluminum sheet. In the aerospace industry, aluminum is widely employed owing to its advantageous characteristics, including a high strength-to-weight ratio, resistance to corrosion, and excellent formability. By using aluminum sheet for these structural components, it becomes possible to construct aircraft that are lightweight, a crucial factor for optimizing fuel efficiency and performance. Moreover, aluminum is readily accessible and cost-effective, making it a favored option for aerospace applications. Nevertheless, it is worth mentioning that the selection of the aluminum sheet's specific grade and thickness will depend on the precise requirements and specifications of the aerospace structural component.

- Q: ive been working with parts for a robot without gloves and ive manged to 3 cuts in my fingers, also my hands get covered with powdered aluminum from sanding the peices, can this be dangerous to my health?

- When working with aluminum, wear leather gloves to protect your hands, goggles to protect your eye and a dust mask to protect your lungs. Aluminum has been linked to Alzheimer's and other neurological conditions.

- Q: Can 101 aluminum sheets be customized in terms of size and thickness?

- Certainly! It is possible to customize the size and thickness of 101 aluminum sheets. One can achieve the desired size and thickness by employing diverse cutting methods like shearing, sawing, or laser cutting. Moreover, rolling or stretching the aluminum sheets can also result in the desired thickness. By personalizing the size and thickness of aluminum sheets, they can be tailored to meet specific applications or requirements.

- Q: What specific coatings or treatments are required for aluminum sheets to enhance their properties or protect them?

- <p>Special coatings or treatments for aluminum sheets may be needed depending on the application. Anodizing is a common treatment that enhances corrosion resistance and wear. For aesthetic purposes, aluminum can be painted or coated with a clear lacquer to maintain its appearance. Protective coatings like powder coating or electroplating can be used to improve durability and resistance to environmental factors. In certain industrial applications, aluminum sheets may be treated with specific coatings to enhance thermal or electrical conductivity. The choice of coating or treatment depends on the specific requirements of the project, such as resistance to weather, chemicals, or mechanical stress.</p>

- Q: What are the different methods of surface engraving aluminum sheets?

- There are several methods of surface engraving aluminum sheets, including laser engraving, mechanical engraving, chemical etching, and diamond drag engraving. Each method offers different levels of precision and depth, allowing for various artistic or functional purposes.

- Q: What is the thermal expansion coefficient of aluminum sheets?

- The thermal expansion coefficient of aluminum sheets is approximately 23.1 x 10^-6 per degree Celsius. This means that for every degree Celsius increase in temperature, the aluminum sheet will expand by 23.1 parts per million in length. This coefficient may vary slightly depending on the specific alloy and manufacturing process of the aluminum sheet.

- Q: Can aluminum sheets be used for chemical reactors?

- Yes, aluminum sheets can be used for chemical reactors. Aluminum is often chosen for its corrosion resistance, lightweight properties, and ability to withstand high temperatures, making it suitable for various chemical processes in reactor applications. However, it is important to consider the specific chemical reactions and conditions involved, as certain chemicals or extreme conditions may chemically react with or degrade aluminum.

- Q: This question asks for a comparison of the positive and negative aspects of utilizing aluminum sheets in building construction.

- <p>Aluminum sheets in construction offer several advantages, including lightweight properties that reduce structural load, excellent corrosion resistance, and durability which minimizes maintenance needs. They are also energy-efficient, reflecting heat and reducing cooling costs. Additionally, aluminum is recyclable, contributing to sustainability. Disadvantages include higher initial costs compared to some traditional materials and potential for dents or damage from impacts. Aluminum can also be noisy when walked on, and it may require additional insulation for thermal performance, adding to the overall cost.</p>

- Q: How does the formability of aluminum sheet vary with different alloys?

- The formability of aluminum sheet can vary significantly with different alloys. Some aluminum alloys have excellent formability, allowing for easy bending, shaping, and forming without cracking or tearing. These alloys are commonly used in applications that require complex shapes or intricate designs. On the other hand, certain aluminum alloys may have lower formability, making them more difficult to shape without the risk of deformation or failure. The choice of alloy will depend on the specific requirements of the application and the desired level of formability needed.

Send your message to us

2A12 5052 5083 6061 6083 7075 Aluminum Sheet Price per kg

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords