Polishing Aluminum Profiles for Radiator Covers Manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Polishing Aluminium Profiles Manufacturer Description:

Polishing Aluminium Profiles Manufacturer (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of thePolishing Aluminium Profiles Manufacturer:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

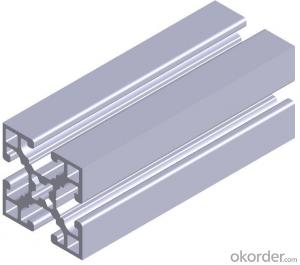

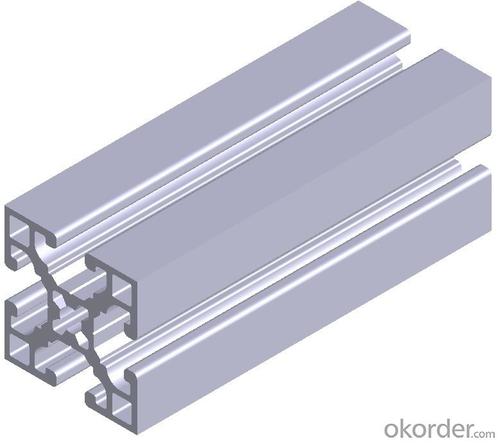

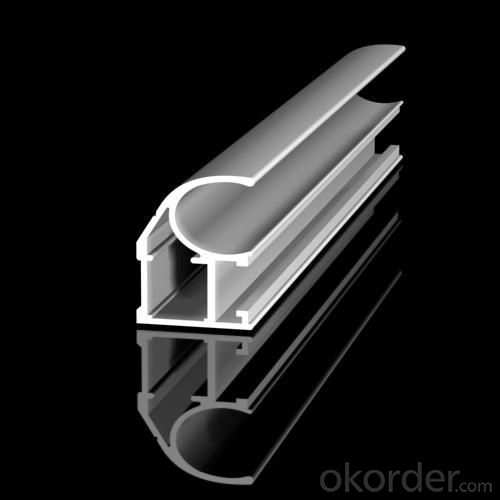

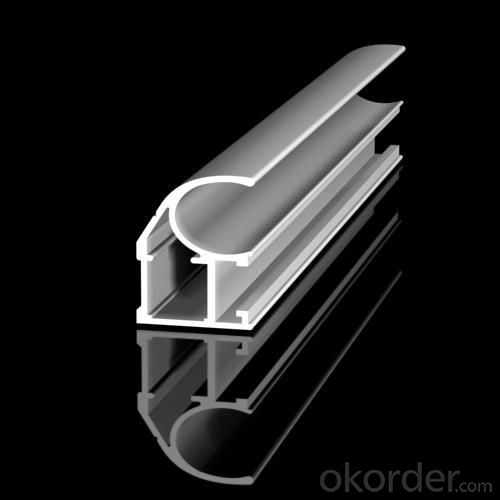

3.Polishing Aluminium Profiles Manufacturer Images:

4.Polishing Aluminium Profiles ManufacturerSpecification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: could aluminum sheet be attracted by magnet?

- no, it couldn't.

- Q: Using thin copper sheets and thin aluminum sheets, respectively, from heat source heat conduction to aluminum heat sink, which kind of efficiency is higher?

- Copper is second only to silver as a conductor of heat. The coefficient of thermal conductivity is 398W/mK at room temperature, while aluminum is 236W/mK.The important thing is say three times: please adopt! Please adopt! Please adopt!

- Q: The user is inquiring if it's possible to incorporate recycled aluminum sheets into their project.

- <p>Yes, you can use recycled aluminum sheets in your project. Recycled aluminum is not only environmentally friendly but also cost-effective. It maintains the same strength and durability as new aluminum, making it suitable for various applications. Ensure the recycled aluminum meets your project's specifications and quality standards. Always check for any impurities or inconsistencies that might affect the performance of your project. Using recycled materials can also contribute to sustainability and reduce waste.</p>

- Q: Are aluminum sheets resistant to chemicals?

- Yes, aluminum sheets are generally resistant to a wide range of chemicals.

- Q: Can aluminum sheet be used for heat exchangers?

- Yes, aluminum sheet can be used for heat exchangers. Aluminum is a commonly used material for heat exchangers due to its excellent thermal conductivity, light weight, and corrosion resistance. The high thermal conductivity of aluminum allows for efficient transfer of heat between fluids, making it suitable for various heat exchange applications. Additionally, aluminum is available in different alloys and thicknesses, providing flexibility in design and customization for specific heat exchanger requirements. Overall, aluminum sheet is a popular choice for heat exchangers in industries such as automotive, HVAC, and aerospace.

- Q: Aluminum knowledge. What is the model 3003 H24? What does H mean?

- 3003 is aluminium manganese alloy aluminum plate (Al--Mn), which is mainly composed of manganese.H24: continuous casting, continuous rolling, Zhang Liqiang and partial toughening.Is the aluminum plate with a thickness of more than 0.2mm to 500mm, 200mm width, length less than 16m aluminum material called aluminum plate or aluminum sheet, aluminum is below 0.2mm, 200mm within the width of the row material or bar (of course, with the progress of the large equipment, the width can be 600mm row material also more). Aluminum sheet refers to the rectangular plate made of aluminium ingot rolled and divided into pure aluminum plate, alloy aluminum plate, thin aluminum plate, middle thick aluminum plate and pattern aluminum plate.Aluminium alloy is added in the process of aluminum alloy elements (main alloying elements copper, silicon, magnesium, zinc, manganese, minor alloying elements such as nickel, iron, chromium, titanium, lithium, etc.) in order to improve the mechanical properties of aluminum and chemical index. Alloy aluminum sheet has some special properties of pure aluminum plate, and is widely used in special environment, such as ship, refrigerator, mould, aerospace equipment, etc..

- Q: Can aluminum sheet be welded?

- Yes, aluminum sheet can be welded. Aluminum is a versatile metal that can be easily welded using various techniques such as gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and resistance spot welding (RSW). However, welding aluminum requires special considerations due to its high thermal conductivity and low melting point compared to other metals. It is important to choose the appropriate welding process, filler material, and shielding gas to ensure a successful weld. Additionally, proper surface preparation, including cleaning and removing any oxide layer, is crucial for achieving a strong and durable weld in aluminum sheet.

- Q: Aren't metals in general (and aluminium in particular) excellent heat conductors?

- Yes aluminium is a good heat conductor, which is why it is used as a heatsink to dissipate heat from electronic components like the CPU in you laptop. The idea of the aluminium stand for your laptop is to raise it up from the desktop surface, allowing air to pass between the gap and extract the heat from the aluminium stand as your laptop heats up with use.

- Q: What are the different types of finishes available for painted aluminum sheets?

- There are several different types of finishes available for painted aluminum sheets, each offering unique characteristics and benefits. 1. Matte Finish: This finish provides a non-reflective, dull appearance to the painted aluminum sheet. It is commonly used in applications where a low-gloss finish is desired, such as architectural elements or interior design. 2. Gloss Finish: A gloss finish gives the painted aluminum sheet a shiny, reflective surface. It is often chosen for applications where a sleek and polished appearance is desired, such as automotive parts or decorative panels. 3. Textured Finish: A textured finish adds a raised pattern or texture to the surface of the painted aluminum sheet. This type of finish is commonly used for decorative purposes, as it can enhance the visual appeal and provide a unique tactile experience. 4. Metallic Finish: A metallic finish gives the painted aluminum sheet a metallic appearance, resembling the look of metal alloys like stainless steel or bronze. This finish is frequently used in architectural applications to achieve a modern and high-end aesthetic. 5. Powder Coating Finish: Powder coating is a popular finishing method that involves applying a dry powder to the surface of the painted aluminum sheet and then curing it under heat. This process creates a durable and seamless finish that is resistant to chipping, scratching, and fading. 6. Clear Coat Finish: A clear coat finish is often applied over a painted aluminum sheet to provide an extra layer of protection and enhance its durability. This finish is typically transparent and helps to resist damage from UV rays, moisture, and other environmental factors. It is important to consider the intended use and desired aesthetic when choosing a finish for painted aluminum sheets, as each type offers its own unique benefits and characteristics.

- Q: According to the reactivity of metals, aluminum chloride (AlCl3) will not react with copper (Cu). But I am almost sure that the copper nail I put in the aluminum chloride solution became shiny and lost its copper lust. Why did this reaction happen?

- it particularly is authentic that many deodorants, quite those categorized anti-perspirants, incorporate aluminum chloride as an lively ingredient. Aluminum chloride does decrease sweat production via the sweat glands that are placed interior the floor and are quite ample under the hands. For some people who're heavy sweaters this drying consequence is amazingly significant. despite the fact that those deodorants decrease sweat production they do no longer block the sweat glands. we are no longer attentive to any at as quickly as risky outcomes on maximum persons from making use of a deodorant containing aluminum chloride. In our very close society at present, physique hygiene and prevention of physique smell are significant. in case you do no longer use a deodorant you are able to discover your persons the two complaining or keeping off you. while you're worried with reference to the drying consequence seem for a deodorant that would not incorporate aluminum chloride.

Send your message to us

Polishing Aluminum Profiles for Radiator Covers Manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords