Aluminum Structural Building Profiles - 6063 Alloy T5 Aluminium Profile for Doors and Windows

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminium Profile to Make Doors and Windows 6063 Alloy T5 Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminium Profile to Make Doors and Windows 6063 Alloy T5 :

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

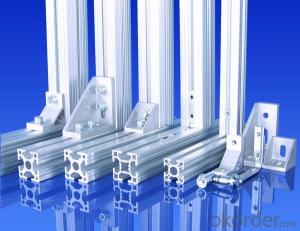

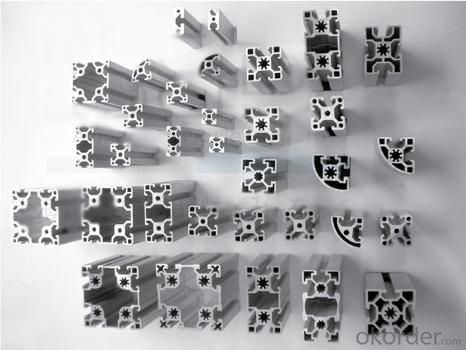

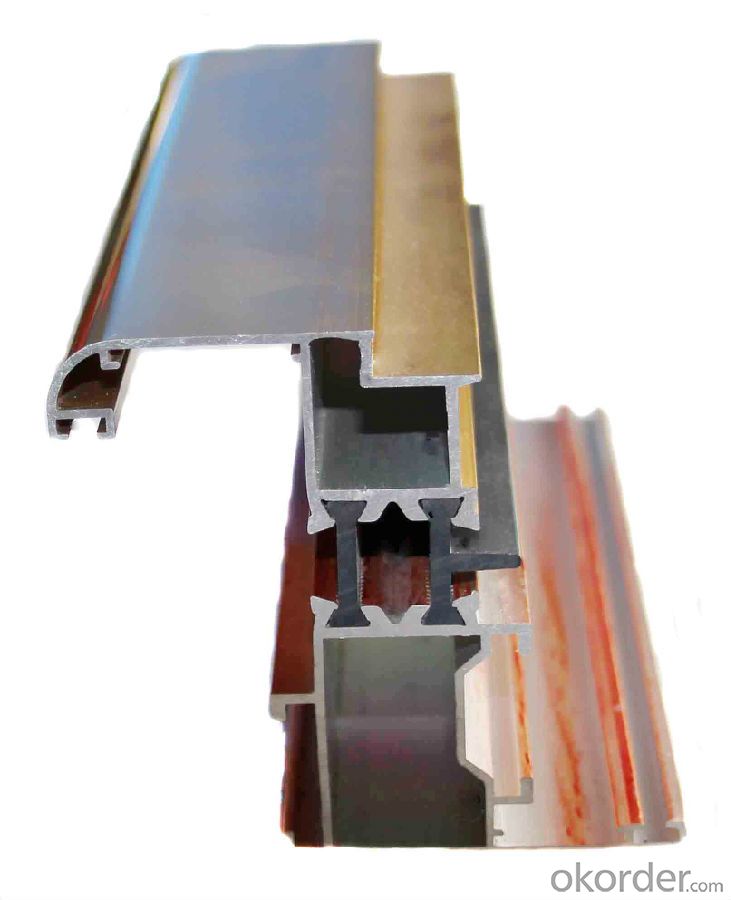

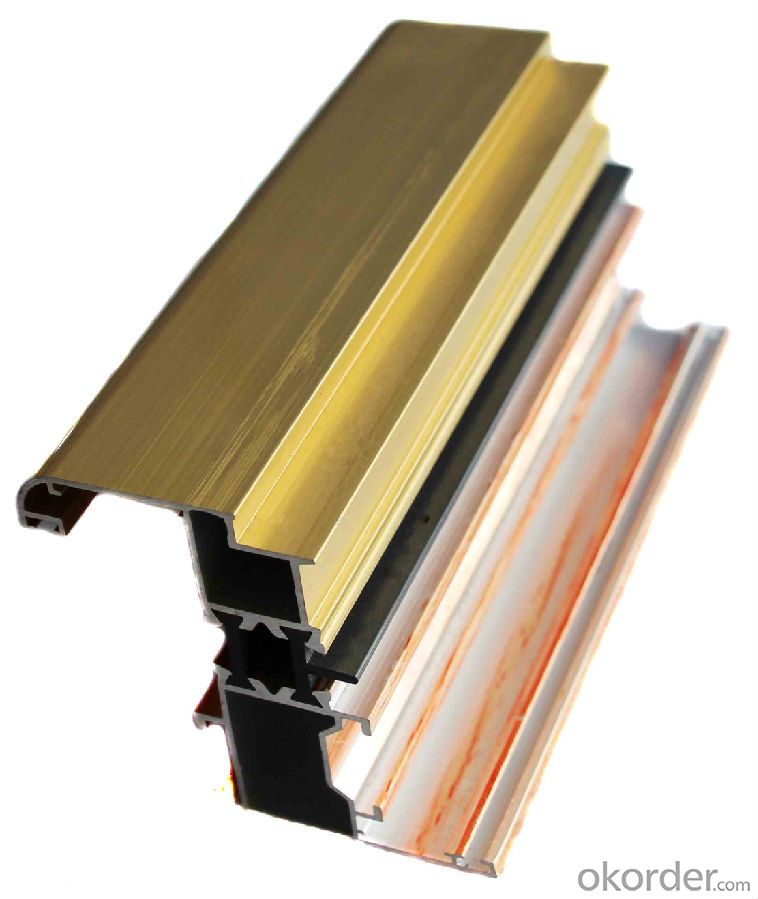

3.Aluminium Profile to Make Doors and Windows 6063 Alloy T5 Images:

4.Aluminium Profile to Make Doors and Windows 6063 Alloy T5 Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How do you prevent warping or distortion of aluminum profiles during fabrication?

- In order to prevent warping or distortion of aluminum profiles during fabrication, there are several key measures that can be implemented: 1. Storage in a controlled environment is crucial prior to fabrication. It is essential to store the aluminum profiles in an environment with stable temperature and humidity levels. This will help minimize any potential changes in the shape or dimensions of the metal. 2. Proper handling techniques must be employed to avoid bending or twisting the aluminum profiles. This includes using appropriate lifting equipment, avoiding excessive force, and ensuring even support during transportation. 3. During the fabrication process, it is important to utilize suitable machining techniques that minimize heat buildup. Excessive heat can cause the aluminum to expand and potentially warp. Utilizing cooling techniques such as lubricants or coolants can disperse heat and prevent distortion. 4. Controlled welding is crucial when working with aluminum profiles. Maintaining proper control over the welding process is essential. Employing appropriate welding techniques, such as preheating and post-weld heat treatment, can help minimize distortion. 5. Adequate fixturing methods should be employed during fabrication to ensure that the aluminum profiles are held in the correct position throughout the process. This prevents unintended bending or warping that could occur due to improper support or clamping. 6. Stress-relieving processes can be implemented after fabrication to minimize residual stresses within the aluminum profiles. This will prevent distortion or warping that may occur during subsequent handling or usage. 7. Regular inspection and measurement of the aluminum profiles during fabrication is necessary to identify any deviations from the desired specifications. This enables prompt corrective actions to be taken, reducing the risk of warping or distortion. By implementing these steps, manufacturers can significantly decrease the likelihood of warping or distortion in aluminum profiles during fabrication, ensuring the production of high-quality components or products.

- Q: I am a mold professional, in school are mainly plastic mold and stamping die, but I am now in an aluminum extrusion die master apprentice. Draw pictures every day and walk around the workshop. But I have never met any related knowledge before, and I don't know where to start. I don't know what to do. Sometimes even want to give up, but not reconciled. I hope you can give me some advice. Thank you very much!!!

- From the process should start with its principle should be the same as extruded acrylic, before I was doing the plastic mold design, aluminum is also don't know is how to do it, then to the friend's factory seen their company production of acrylic rods, know is squeezed out. Aluminum extrusion type is, should the principle is the same, I have no contact with the mold design of aluminum, the questions you can answer you here, sorry oh!

- Q: This question asks for methods to guarantee the safety and reliability of aluminum profile installations.

- <p>To ensure that the installation of aluminum profiles is safe and reliable, follow these steps: Use high-quality aluminum profiles that meet industry standards. Ensure proper measurements and accurate cuts to fit the profiles perfectly. Use appropriate fasteners and hardware that are compatible with aluminum. Ensure that all connections are secure and that the profiles are properly aligned. Check for any sharp edges or protrusions that could cause injury. Test the stability and load-bearing capacity of the installation to ensure it can handle the expected weight and stress. Regularly inspect and maintain the aluminum profiles to prevent any potential issues.</p>

- Q: Can aluminum profiles be used in lighting fixture manufacturing?

- Aluminum profiles are indeed suitable for the manufacturing of lighting fixtures. In the lighting industry, aluminum is widely employed because of its many advantageous qualities. It possesses light weight, durability, and corrosion resistance, which make it perfect for both indoor and outdoor lighting fixtures. By easily molding and manipulating aluminum profiles, one can create diverse designs and forms, thereby enabling innovative and imaginative lighting solutions. Moreover, these profiles can be coated or anodized, thereby enhancing their visual appeal and providing extra protection against damage. All in all, due to their versatility, functionality, and aesthetic appeal, aluminum profiles are highly favored in the manufacturing of lighting fixtures.

- Q: This question asks for an overview of the various types of fasteners that can be used in conjunction with aluminum profiles.

- <p>Aluminum profiles are commonly used in construction and manufacturing, and they require fasteners for assembly. The different types of fasteners include: 1. T-nuts and T-bolts: These are used for creating strong connections within the profile. 2. Clamping blocks: These are used to secure profiles together without the need for drilling. 3. Corner brackets: These are used to create 90-degree connections between profiles. 4. Angle brackets: Similar to corner brackets but for creating angled connections. 5. End caps: These are used to cover the ends of profiles for a finished look. 6. Dowels: These are used for aligning and joining profiles together. 7. Screws and bolts: These are used for securing components to the profiles. Each type of fastener serves a specific purpose and is chosen based on the particular application and design requirements.</p>

- Q: Can aluminum profiles be used for display systems?

- Certainly, display systems can indeed make use of aluminum profiles. The lightweight and sturdy characteristics of aluminum make it a popular option for such systems. Its versatility allows for easy customization to meet the specific needs of the display system. Frames, shelves, stands, and other components of the display system can all be created using aluminum profiles. Moreover, aluminum profiles are resistant to corrosion, making them suitable for both indoor and outdoor display applications. Furthermore, they provide a sleek and contemporary aesthetic, enhancing the visual appeal of the display system. In conclusion, aluminum profiles are a trustworthy and effective choice when designing and constructing display systems.

- Q: Can aluminum profiles be used for staircases and handrails?

- Yes, aluminum profiles can be used for staircases and handrails. Aluminum is lightweight, durable, and resistant to corrosion, making it an ideal material for these applications. Additionally, aluminum profiles offer versatility in terms of design options and can be easily customized to suit specific requirements.

- Q: How to distinguish the good or bad of aluminum profile simply?

- With customers in the process of aluminum found billion purchase of aluminum profile, most do not know how to see the quality of aluminum profiles. And sometimes, many users in order to save costs, and select some cheaper industrial aluminum to do the work table stent, resulting in not long after the emergence of cracking, fading situation.

- Q: Can aluminum profiles be used for signage?

- Signage can indeed utilize aluminum profiles. Aluminum, a material known for its versatility and durability, is commonly utilized in various signage applications. It boasts numerous advantages, including its lightweight nature, resistance to corrosion, and ease of manipulation. Aluminum profiles can be effortlessly shaped into diverse forms and sizes, rendering them suitable for a vast array of signage needs. Furthermore, these profiles can be powder coated or painted to attain the desired color and finish, thereby enhancing the signage's overall appearance. Notably, aluminum is an environmentally friendly option for signage projects as it is highly recyclable, contributing to its sustainability. All in all, due to their durability, versatility, and aesthetic appeal, aluminum profiles remain a favored choice for signage projects.

- Q: What specific coatings or treatments are necessary for aluminum profiles to be used outdoors?

- <p>For outdoor use of aluminum profiles, special coatings or treatments are often required to protect against weathering, corrosion, and UV damage. Anodizing is a common process that increases the durability and resistance of aluminum. Powder coating is another method used for additional protection and to provide a wide range of colors. Some profiles may also be treated with a clear coat to maintain the natural look of aluminum while still offering protection. It's important to select the appropriate treatment based on the specific environmental conditions and aesthetic requirements of the application.</p>

Send your message to us

Aluminum Structural Building Profiles - 6063 Alloy T5 Aluminium Profile for Doors and Windows

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords