Aluminum Profiles South Africa for Specifications of Auto-Parts Applications

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

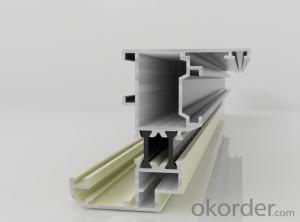

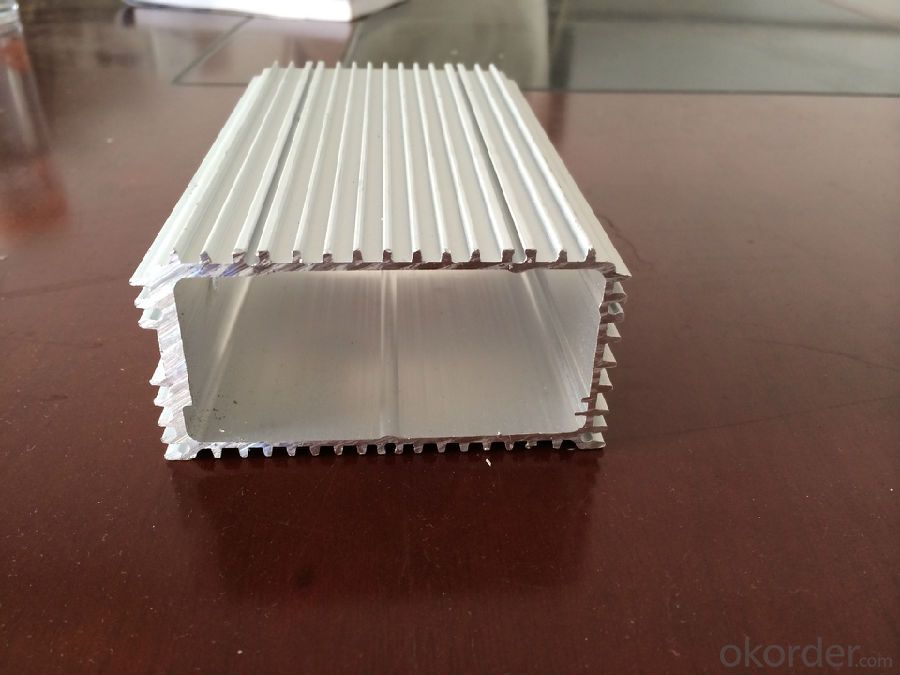

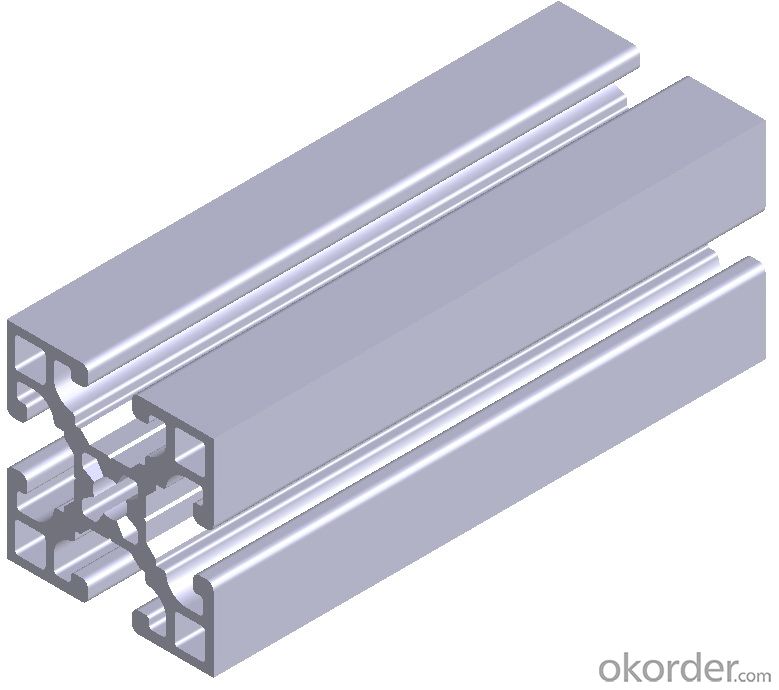

Structure of Aluminium Profile for Specifications of Auto-parts Applications Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Profile for Specifications of Auto-parts Applications:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

Images of the Aluminium Profile for Specifications of Auto-parts Applications:

Aluminium Profile for Specifications of Auto-parts Applications Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ Aluminium Cast Slab not Alloyed in Coil Form:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: This question asks for a comparison of the benefits and drawbacks of utilizing aluminum profiles within the construction industry.

- <p>Aluminum profiles offer several advantages in construction, including high strength-to-weight ratio, corrosion resistance, and ease of fabrication. They are lightweight, which reduces the load on structures and facilitates easier installation. Their resistance to corrosion means they require less maintenance and have a longer lifespan compared to steel. Additionally, aluminum profiles can be easily cut, bent, and joined, making them versatile for various applications. However, they have some disadvantages, such as lower thermal conductivity, which can be a concern in temperature-sensitive environments. They are also more expensive than some traditional materials like steel. Lastly, aluminum profiles can dent or deform under heavy loads, which may limit their use in certain structural applications.</p>

- Q: How about the weight calculation of 180 series semi concealed curtain wall aluminum profile

- A section of properties in CAD labeled dynamic block, the section area and mark block association graph can be easily calculated, section area, surface area, weight theory, and the setting up of a variety of materials such as aluminum options.

- Q: What are the applications of aluminum profiles?

- Due to their unique characteristics and properties, aluminum profiles have a wide range of applications in various industries. Some of the main uses of aluminum profiles are as follows: 1. In the construction industry, aluminum profiles are extensively employed for windows, doors, curtain walls, and structural components. Their excellent strength, durability, and corrosion resistance make them ideal for building purposes. 2. The automotive industry utilizes aluminum profiles to manufacture lightweight and fuel-efficient vehicles. They are used in the production of car frames, engine mounts, heat exchangers, and other structural components. 3. The aerospace industry relies on aluminum profiles for their high strength-to-weight ratio. They are used in the construction of aircraft frames, wings, fuselage, and other critical components. 4. Aluminum profiles are widely used in electrical and electronics applications. Their excellent thermal conductivity and electrical insulation properties make them suitable for manufacturing heat sinks, LED lighting fixtures, electrical enclosures, and electronic device housings. 5. The furniture industry is increasingly incorporating aluminum profiles to create lightweight and stylish furniture pieces. They are used in the production of chairs, tables, cabinets, and shelving systems, providing a modern and aesthetic appeal. 6. Aluminum profiles play a significant role in the manufacturing of industrial machinery and equipment. They are utilized in the construction of conveyor systems, assembly line structures, machine frames, and guarding systems due to their lightweight, durability, and ease of fabrication. 7. In the marine industry, aluminum profiles are commonly used for their corrosion resistance and lightweight properties. They are utilized in the construction of boat frames, masts, hulls, and other marine structures. 8. Aluminum profiles also find applications in renewable energy systems such as solar panels and wind turbines. They are used in the manufacturing of solar panel frames, wind turbine supports, and mounting structures due to their lightweight nature and corrosion resistance. Overall, aluminum profiles offer a versatile and cost-effective solution for various industries, meeting their specific requirements for strength, durability, lightweight, and corrosion resistance.

- Q: Are aluminum profiles suitable for use as interior finishing materials, specifically for flooring and wall panels?

- <p>Yes, aluminum profiles can be used for interior finishing materials such as flooring and wall panels. They are known for their durability, low maintenance, and resistance to corrosion. Aluminum profiles are lightweight, easy to install, and can be used in various designs and styles, making them a popular choice for modern interior design. They also offer the advantage of being recyclable and environmentally friendly.</p>

- Q: What are the advantages of using aluminum profiles in the oil and gas industry?

- There are several advantages of using aluminum profiles in the oil and gas industry. Firstly, aluminum profiles offer exceptional strength-to-weight ratio. This means that they provide high structural integrity while being lightweight, which is crucial in industries like oil and gas where equipment needs to be transported and installed in various locations. The lightweight nature of aluminum profiles also reduces the load on structures and equipment, resulting in energy savings and improved efficiency. Secondly, aluminum profiles are highly corrosion-resistant. The oil and gas industry often operates in harsh environments, including exposure to saltwater, chemicals, and extreme temperatures. Aluminum's natural oxide layer acts as a protective barrier, preventing corrosion and ensuring durability in these challenging conditions. This resistance to corrosion significantly reduces maintenance and replacement costs over the lifespan of the equipment. Additionally, aluminum profiles are non-magnetic, making them suitable for applications where magnetic interference is a concern. In the oil and gas industry, where precision and accuracy are crucial, the non-magnetic nature of aluminum profiles ensures that equipment operates without any electromagnetic interference, ensuring data accuracy and reliable performance. Furthermore, aluminum profiles can be easily fabricated and customized to meet specific requirements. They can be extruded into various shapes, sizes, and configurations, allowing for endless design possibilities. This flexibility in manufacturing makes aluminum profiles highly versatile, enabling them to be used in a wide range of applications within the oil and gas industry, including pipe racks, platforms, support structures, and access systems. Lastly, aluminum is a sustainable and environmentally friendly material. It is 100% recyclable without losing its properties, making it a sustainable choice for the oil and gas industry that increasingly focuses on reducing its carbon footprint. Aluminum's recyclability also contributes to cost savings and resource conservation. In summary, the advantages of using aluminum profiles in the oil and gas industry include their high strength-to-weight ratio, corrosion resistance, non-magnetic properties, easy fabrication, and recyclability. These characteristics make aluminum profiles a reliable and cost-effective solution for various applications in this industry.

- Q: Can aluminum profiles be used in the construction of retail displays?

- Yes, aluminum profiles can be used in the construction of retail displays. Aluminum profiles are lightweight, durable, and versatile, making them an ideal material for creating custom retail displays. They can be easily manipulated to create various shapes and sizes, allowing for flexibility in design. Additionally, aluminum profiles can be powder coated or anodized in different colors and finishes to enhance the aesthetics of the retail displays.

- Q: What are the potential effects on the environment when aluminum profiles are used in the construction of buildings?

- <p>The use of aluminum profiles in building construction has both positive and negative environmental impacts. On the positive side, aluminum is lightweight, which reduces the energy required for transportation and can contribute to a building's energy efficiency. It is also recyclable, with a high recycling rate, which helps to conserve resources and reduce waste. However, the production of aluminum is energy-intensive and generates greenhouse gas emissions. Additionally, the extraction of bauxite, the primary source of aluminum, can lead to deforestation and habitat destruction. The environmental impact of using aluminum profiles in construction must therefore be balanced against these factors.</p>

- Q: Can aluminum profiles be used for display systems?

- Yes, aluminum profiles can be used for display systems. They are lightweight, durable, and versatile, making them ideal for creating custom display structures such as exhibition booths, retail displays, and signage. Aluminum profiles can be easily assembled, disassembled, and reconfigured, allowing for flexibility and easy transportation. Additionally, they can be powder-coated or anodized in various colors to match the desired aesthetic. Overall, aluminum profiles offer a reliable and cost-effective solution for display system applications.

- Q: How do aluminum profiles perform in terms of creep resistance?

- Aluminum profiles generally exhibit good creep resistance. Creep is the tendency of a material to deform under constant load over time. Aluminum profiles tend to have a low creep rate compared to other materials, making them suitable for applications where long-term structural stability is required. The high strength-to-weight ratio of aluminum profiles also contributes to their creep resistance, as they can withstand heavy loads without significant deformation. However, it is important to note that the creep resistance of aluminum profiles can be influenced by various factors such as alloy composition, heat treatment, and operating conditions. Proper design and engineering considerations should be taken into account to ensure optimal creep performance in specific applications.

- Q: What are the differences between aluminium profiles 6063 and 6463?

- 6063 aluminum introduction: Standard: GB/T 3191-1998, commodity name: 6063 aluminum bar, 6063 aluminum alloy bar.6063 aluminum alloy is a moderate strength heat treatment alloy in AL-Mg-Si system.

Send your message to us

Aluminum Profiles South Africa for Specifications of Auto-Parts Applications

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords