Very Thin Aluminum Sheets - Aluminium Coils for Color Coated Polyester 22-45 Microns

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminium Coils for Color Coated Polyester 22-45 microns

Aluminium Coils for Color Coated Polyester 22-45 microns is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Aluminium Coils for Color Coated Polyester 22-45 microns

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

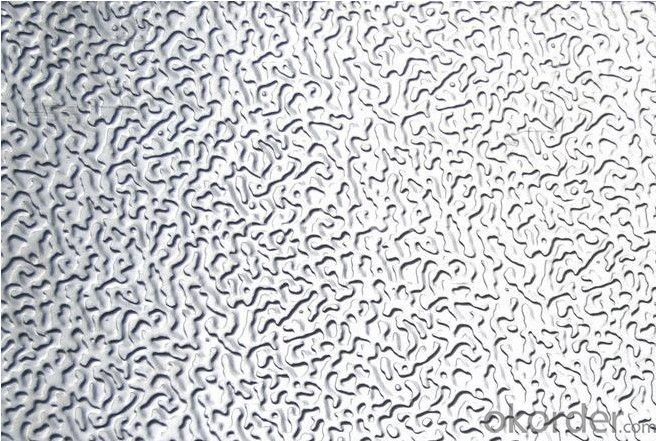

3. Image of Aluminium Coils for Color Coated Polyester 22-45 microns

4. Product Specification of Aluminium Coils for Color Coated Polyester 22-45 microns

| Alloy | Temper | Style | Thickness | Width |

| AA1100 | H14 | Direct Casting | 0.2mm-3mm | 1000mm-1500mm |

5.FAQ of Aluminium Coils for Color Coated Polyester 22-45 microns

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: I was hoping someone could explain aluminum corrosion with degreasers and cleaning formulas for automotive cleaning. This starts with, where is this aluminum (wheels)?, what types of cleaners?, do cleaners cause corrosion? Any insights would be appreciated.

- Contrary to popular believe, aluminum oxidizes just like steel. Steel rusts to a reddish color. Aluminum rusts to a white color and looks more like corrosion. Aluminum cleaners or cleaners safe for aluminum usually clean without staining the aluminum surface. Hardly any cleaner for for automotive use will corrode aluminum. Visit your local auto parts store and read the labels for a wheel cleaner that is 'safe' for aluminum. You should be able to use it on all aluminum surfaces.

- Q: what's the oxidation method of positive pole on the surface of aluminum sheet?

- Do chemical polishing again, oxidation time is about 40 – 90 minutes, after finishing all of these, you can conduct positive pole oxidation, choose sulfuric acid solution in normal situation, pretreatment is very important in the whole process, take stereo as negative pole, firstly, use the solution mixed of carbonate-bicarbonate and detergent to heat and clean its surface, pretreat the aluminum sheet, dyeing according to requirement after oxidation, then remove the oxide film with oxide film removal solution, place aluminum sheet on the positive pole, finally closing it in the boiling water for about 15 minutes.

- Q: Are aluminum sheets resistant to chemicals?

- Aluminum sheets, in general, possess resistance to a wide range of chemicals. This is due to the presence of a natural oxide layer on the surface of aluminum, which acts as a protective shield against corrosion and chemical reactions. The stability of this oxide layer enables it to withstand the effects of most acids, alkalis, and organic solvents. However, it should be noted that certain chemicals, such as strong acids or bases, as well as some halogenated compounds, have the capacity to corrode aluminum. Moreover, prolonged exposure to particular chemicals or extreme conditions may compromise the integrity of the oxide layer, rendering aluminum more susceptible to corrosion. Consequently, when considering the use of aluminum sheets in specific applications, it is crucial to carefully evaluate the chemical environment and potential interactions.

- Q: This question asks for the typical dimensions of aluminum sheets utilized in the construction industry.

- <p>The standard size for aluminum sheets used in construction can vary depending on the region and specific application. However, commonly used sizes include 4x8 feet, 4x10 feet, and 5x10 feet. These sheets are typically 0.020 to 0.060 inches thick. It's important to note that custom sizes are also available to meet specific project requirements. Always check with local suppliers or industry standards for the most accurate sizing information.</p>

- Q: What types of bonds can aluminum form: Covalent, Ionic and/or Metallic?Could you post the source, I've been looking for a while now :/

- Aluminum Bonds

- Q: Can aluminum sheets be used for automotive applications?

- Yes, aluminum sheets can be used for automotive applications. Aluminum is a lightweight and corrosion-resistant material, making it ideal for various automotive components. It is commonly used in the construction of car bodies, engine parts, wheels, and other structural components. Aluminum sheets offer excellent strength-to-weight ratio, which helps improve fuel efficiency and overall performance of vehicles. Additionally, aluminum has good thermal conductivity, allowing for effective heat dissipation in automotive applications. Overall, the use of aluminum sheets in automotive manufacturing has become increasingly popular due to its numerous advantages.

- Q: I want to make a dress from aluminum cans. However, aluminum is very sharp once cut. So, do you thing there is a possible way to make the cut edges less sharp? Would sanding the edges help?

- It's a soft metal so sanding and filing would work. You could also consider folding over the sharp edges (like a hemline) using a pliers or similar tool

- Q: This question asks for the steps or methods required to install aluminum sheets on a rooftop.

- <p>To install aluminum sheets on a roof, follow these steps: 1. Inspect the roof structure for any damage and ensure it can support the weight of the aluminum sheets. 2. Measure and cut the aluminum sheets to the required size using a metal saw. 3. Attach a drip edge to the eaves to prevent water from seeping under the sheets. 4. Lay the first sheet horizontally on the roof, starting from the bottom edge, and secure it with roofing nails. 5. Overlap the subsequent sheets by about 1-2 inches and fasten them with nails, ensuring a watertight seal. 6. Install flashing around vents, chimneys, and other roof projections to prevent leaks. 7. Seal all seams and fasteners with a high-quality sealant to ensure a weathertight installation. 8. Inspect the installation for any gaps or leaks and make necessary adjustments.</p>

- Q: Can aluminum sheets be bent or formed?

- Yes, aluminum sheets can be bent or formed. Aluminum is a highly malleable and ductile metal, which means it can easily be shaped or bent without breaking. This characteristic makes it a popular choice for various applications, such as manufacturing automotive parts, aircraft structures, and household items. Aluminum sheets can be bent or formed using various techniques, such as press braking, roll bending, and stretch forming. These methods allow the aluminum sheets to be shaped into different angles or curves to meet specific design requirements.

- Q: Can aluminum sheet be used for electronic components?

- Yes, aluminum sheet can be used for electronic components. Aluminum is a commonly used material in the electronics industry due to its lightweight, corrosion resistance, and good thermal conductivity. It is often used for heat sinks, casings, and electrical connectors in various electronic devices.

Send your message to us

Very Thin Aluminum Sheets - Aluminium Coils for Color Coated Polyester 22-45 Microns

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords