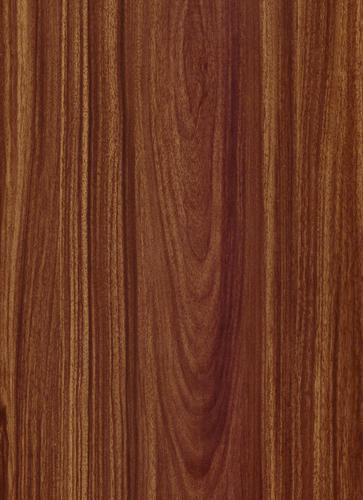

1 2 in Aluminum Coil with Wood Grain Coating

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium coated sheetand coil choose aluminium sheet coil as raw material, after de-ester, cleaning,passivation layer processing, and then painting on this basis, the paint areprovided by famous international companies like PPG and Valspar from UnitedStates or Becker from Sweden, represent the most advanced level in the world.After the test of exposure by natural light in Florida, the quality assurance is more than morethan 20 years. As poor performance of color coated steel corrosion, rust,yellow rust after a large amount of the deficiency of serious impact on thebuilding's overall appearance. However, because of the advantages of rawmaterials, Aluminium coated coil have a high strength, corrosion resistance,high weather resistance, can be used recycle, save energy and protect theenvironment and other characteristics. Not only have the same strength with colorcoated steel, but also overcome the shortage of color coated steel. So, the Aluminiumcoated coil has been widely used as roofing and ceiling decorative envelopesystem board in modern constructions like large factories, exhibition halls,stadiums, airports, train station hospital and so on. We can choose Aluminiumcoated coil in different thickness and color, by cutting, pressing, punching,bending and other follow-up molding process for large span, the larger theoverall roofing, wall decorative panels used in construction; or cut them intosmall panels by bending, stamping mold or other processing for indoordecorative roofing plate; we can also composite them with polyurethane foam oraluminium honeycomb for energy-saving decorative wall plates.

Alloy | 1050,1060,1100,3003,3004,3005,3104,3105,5052,5005,8011 |

Temper | O,H42,H44,H46,H48 |

Thickness (mm) | 0.25mm-1.5mm for aluminium coated coil; 1.50mm-4.0mm for aluminium coated sheet. |

Width (mm) | 100mm to 2000mm |

Length (mm) | 800mm to 6000mm for sheet |

- Q: What are the differences between aluminum coil 3003h24 and 3a21h14?

- The mechanical property references of rolled plate 3003 H24and 3A21 H14 are as follows: 3003 H24--Rm/MPa≧140-180;Rp0.2/MPa≧115;A(%)≧1-5(thickness 0.2mm-4.5mm)3A12 H14--Rm/MPa≧145-215;A(%)≧6

- Q: I have my brother's old wooden crutches but i see everyone using aluminum and i have the option to get aluminum ones. Is there any reason why they'd be better then my wooden ones?

- Aluminum are lighter..........And I guess after a day of using Wooden Crutches...you can get really tired because of the exra weight your lugging around.

- Q: How are aluminum coils protected during shipping?

- Aluminum coils are typically protected during shipping by being wrapped in a layer of protective film or paper, secured with strapping or bands, and then placed on pallets or in crates. Additionally, they may be enclosed in metal or wooden containers to provide further protection against external damage during transit.

- Q: Can aluminum coils be used in the manufacturing of electronic devices?

- Yes, aluminum coils can be used in the manufacturing of electronic devices. Aluminum has excellent electrical conductivity and thermal properties, making it suitable for various applications in electronics, such as in transformers, inductors, and heat sinks. Its lightweight nature and corrosion resistance also make it a popular choice for electronic components.

- Q: This question asks for methods to protect aluminum coils from damage during storage and transportation.

- <p>To prevent damage to your aluminum coil during storage or transportation, follow these guidelines: Store the coils in a dry and clean environment to prevent moisture and dirt accumulation. Ensure that the storage area is well-ventilated to avoid condensation. Use appropriate padding or separators between coils to prevent scratching or denting. Handle the coils with care, using proper lifting equipment to avoid dropping or mishandling. Secure the coils during transportation to prevent movement that could lead to damage. Keep the coils away from corrosive substances and extreme temperatures. Regularly inspect the coils for any signs of damage and address any issues promptly.</p>

- Q: How are aluminum coils measured and specified?

- Several key factors are taken into account when measuring and specifying aluminum coils. Gauge or millimeters are typically used to measure the thickness of the coil, which determines its strength and durability. Thicker coils are more robust. The width of the coil, measured in inches or millimeters, is another important specification. It determines the size and coverage area of the coil, with wider coils offering greater coverage. The length of the coil is also crucial and is typically measured in feet or meters. It determines the amount of material available for a specific project. Longer coils are often preferred as they minimize the need for joints during installation. The aluminum alloy and temper used in the coil are specified as well. Different alloys have different mechanical and chemical properties, making them suitable for specific applications. The temper, which refers to the heat treatment process applied to the aluminum, affects its hardness and flexibility. The weight of the coil is an important consideration and is typically measured in pounds or kilograms. It determines the handling and transportation requirements for the coil. Lastly, the surface finish of the coil is specified. Common finishes include mill finish, which is untreated, and coated finishes such as painted or anodized. The surface finish affects the appearance and corrosion resistance of the coil. Overall, the measurement and specification of aluminum coils involve factors like thickness, width, length, alloy, temper, weight, and surface finish. These specifications ensure that the coils meet the desired requirements for various applications.

- Q: How are aluminum coils tested for quality and performance?

- Aluminum coils are tested for quality and performance through a series of rigorous inspection processes. These tests aim to assess the mechanical, chemical, and physical properties of the coils to ensure they meet the required standards. One common test conducted is the visual inspection, where trained technicians examine the surface of the aluminum coils for any visible defects such as scratches, dents, or irregularities in shape. This step is crucial as it helps identify any cosmetic flaws that may affect the overall performance and quality of the coils. Another important test is the dimensional inspection, which involves measuring the thickness, width, and length of the coils to ensure they meet the specified tolerances. This test is critical as it helps guarantee the coils will fit properly in their intended applications and perform optimally. To assess the mechanical properties, various mechanical tests are conducted. One such test is the tensile strength test, which measures the maximum amount of stress a coil can withstand before breaking. This test helps determine the strength and durability of the coils under different operating conditions. Additionally, the hardness test is performed to evaluate the resistance of the coils to indentation or scratching. This test provides insights into the coil's ability to withstand wear and tear, ensuring its longevity. Chemical analysis is another vital aspect of quality testing. The chemical composition of the aluminum coils is examined to ensure it meets the required standards and does not contain any impurities or elements that may compromise the performance or safety of the coils. Furthermore, to assess the thermal properties of the coils, thermal conductivity tests are conducted. These tests measure the coil's ability to conduct heat efficiently, ensuring that it can effectively dissipate heat in applications where it is used. In addition to these tests, other performance evaluations may be conducted depending on the specific application of the aluminum coils. This could include corrosion resistance tests, fatigue tests, or even electrical conductivity tests. These evaluations help determine the coil's ability to perform under different conditions and ensure its reliability and longevity. By subjecting aluminum coils to these comprehensive quality and performance tests, manufacturers can ensure that only the highest quality coils are delivered to customers, meeting their expectations and standards.

- Q: Are aluminum coils suitable for beverage can manufacturing?

- Yes, aluminum coils are suitable for beverage can manufacturing.

- Q: How are aluminum coils stored and transported?

- To ensure the safety and minimize damage of aluminum coils, they are stored and transported in a manner that prioritizes their well-being. Generally, these coils find their place in a warehouse or storage facility, where they are shielded from external elements and potential hazards. They are neatly stacked, taking into account security, and are safeguarded against movement or potential harm by proper padding or spacers. When it comes to transportation, aluminum coils are typically carried in flatbed trucks or shipping containers. These vehicles are equipped with secure tie-downs and restraints that prevent any shifting or damage during transit. It is crucial to ensure the proper securing of the coils to avoid any accidents or mishaps. Moreover, additional precautions are taken during transportation to protect the aluminum coils from potential harm. For instance, the coils may be shielded with protective materials like plastic or fabric, which prevent scratches or dents. In some cases, stretch film or bands may be used to provide extra protection by wrapping or strapping the coils. In summary, the storage and transportation of aluminum coils necessitate careful handling and adherence to safety protocols. This guarantees that the coils maintain their optimal condition and reach their destination without any complications.

- Q: Are aluminum coils suitable for insulation purposes?

- Indeed, aluminum coils are well-suited for insulation purposes due to their exceptional heat and electricity conductivity. This quality makes them a perfect selection for insulation applications. Aluminum coils find utility in a wide range of uses such as HVAC systems, refrigeration units, and electrical wiring. Typically, these coils are coated with an insulating material like polyurethane foam or fiberglass to augment their insulation capabilities. The amalgamation of aluminum and insulation works wonders in impeding the transfer of heat or cold, thereby providing superb thermal insulation. Moreover, aluminum is lightweight, sturdy, and resistant to corrosion, rendering it a dependable choice for long-lasting insulation requirements.

Send your message to us

1 2 in Aluminum Coil with Wood Grain Coating

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords