Menards Aluminum Coil Stock for Colored Foil Rolls of Hairdressing Aluminium

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 box

- Supply Capability:

- 300000 box/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

l Product Description:

Specification :

Status | O |

Alloy Type | 8011 |

Aluminum Content | >99.5% |

Thickness | 9-30 micron |

Length | 9-450m |

Width | 10, 20, 25, 30, 35, 38, 40, 45cm etc. |

l Packaging & Delivery

Packaging detail: Each roll packed with an individual color box or pp bag with printing and shrink package, and with/without blade, then put into Standard export wooden case.or as per customers' requirements. Outer packing: About 4, 6, 12, 20, 24, 48, 60 rolls per carton

Delivery detail: 15-20 days after received deposit

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

Aluminum foil is a popular product in CNBM. With advanced technology and equipment, our company has sold large quantities of aluminum foil to the world.

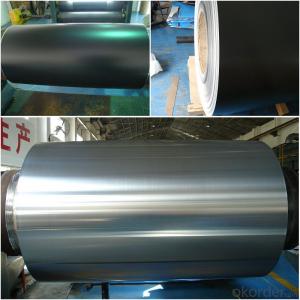

l Product Images

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 20000 boxes

Q: What are your payment terms?

A: We accept L/C, T/T.

l Contact Us

Email:service@okorder.com

- Q: Can aluminum coils be used for electrical transformers?

- Indeed, electrical transformers can utilize aluminum coils. The application of aluminum as a material for transformer coils is attributed to its superior electrical conductivity and cost-effectiveness in comparison to copper. Traditionally, copper has been favored for transformer windings; nevertheless, the utilization of aluminum has gained traction in recent times due to its lighter weight and more affordable price. Additionally, aluminum coils offer advantages in terms of thermal conductivity, as they efficiently dissipate heat in contrast to copper. Nevertheless, it is crucial to take into account the specific demands and design considerations of the transformer, as the decision between aluminum and copper coils may hinge upon factors such as voltage, current, size, and insulation requirements.

- Q: Can aluminum coils be used in marine or saltwater environments?

- Yes, aluminum coils can be used in marine or saltwater environments. Aluminum is known for its excellent corrosion resistance, making it a suitable material for various marine applications. The oxide layer that naturally forms on the surface of aluminum provides a protective barrier against saltwater and other corrosive elements. This oxide layer can be further enhanced through processes like anodizing or painting, which increases its resistance to corrosion. Additionally, aluminum coils are lightweight, which makes them advantageous for marine applications where weight reduction is desired. Overall, aluminum coils are a popular choice in marine and saltwater environments due to their corrosion resistance and lightweight properties.

- Q: Can aluminum coils be used in refrigeration systems?

- Yes, aluminum coils can be used in refrigeration systems. Aluminum is a popular choice for coil materials in refrigeration systems due to its excellent heat transfer properties and corrosion resistance. Aluminum coils are lightweight, durable, and efficient in transferring heat, making them suitable for use in various refrigeration applications such as air conditioning units, refrigerators, and freezers. Additionally, aluminum coils are easier to shape and install compared to other materials, making them a preferred choice for manufacturers.

- Q: Can aluminum coils be used in aerospace applications?

- Indeed, aerospace applications do make use of aluminum coils. The aerospace industry extensively utilizes aluminum due to its lightweight nature and impressive strength-to-weight ratio. Aircraft structures, including fuselages, wings, and landing gear, often incorporate aluminum coils. Moreover, heat transfer and cooling systems also benefit from their presence. The exceptional corrosion resistance and high thermal conductivity of aluminum coils render them fitting for diverse aerospace purposes. Furthermore, their malleability and ease of fabrication enable the creation of intricate shapes and designs necessary for aerospace components.

- Q: What are the different alloys used for aluminum coils?

- There are several different alloys used for aluminum coils, including 1100, 3003, 5052, and 6061. Each alloy has its own unique properties and characteristics, making them suitable for various applications. For example, 1100 is often used for chemical and food processing equipment, while 3003 is commonly used in heat exchangers and cooking utensils. 5052 is known for its high corrosion resistance and is often used in marine and transportation industries. Lastly, 6061 is a versatile alloy used in structural components, aerospace applications, and automotive parts.

- Q: Are aluminum coils suitable for heat sinks?

- Yes, aluminum coils are suitable for heat sinks. Aluminum is a lightweight, highly conductive material that efficiently transfers heat away from electronic components. Its excellent thermal conductivity and corrosion resistance make it a popular choice for heat sink applications.

- Q: What is the purpose or use of aluminum coil in various applications?

- <p>Aluminum coil is a versatile material used in a wide range of applications due to its properties such as lightweight, corrosion resistance, and high thermal and electrical conductivity. It is commonly used in construction for roofing and siding, in the manufacturing of heat exchangers and radiators, and in electrical applications like transformers and power lines. Aluminum coil is also utilized in packaging, such as food and beverage cans, and in automotive and aerospace industries for lightweight components. Its malleability allows it to be easily shaped and formed, making it an ideal material for various industrial processes.</p>

- Q: Are aluminum coils suitable for weather-resistant applications?

- Yes, aluminum coils are suitable for weather-resistant applications. Aluminum is highly resistant to corrosion and can withstand harsh weather conditions, making it an ideal choice for outdoor applications such as roofing, siding, and HVAC systems.

- Q: This question asks if aluminum coils are suitable for use in cold weather conditions.

- <p>Yes, aluminum coils can be used in cold climates. Aluminum is a highly durable material that retains its strength and conductivity even in low temperatures. It does not rust or corrode, making it ideal for outdoor applications in cold weather. However, it's important to ensure that the aluminum coils are properly insulated and protected from extreme temperature fluctuations to prevent any potential damage. Additionally, the design and installation should consider the specific environmental conditions to maximize efficiency and longevity.</p>

- Q: Does anyone know of any men's deodorant that doesn't contain aluminum? It has to be strong, as I do sweat a lot.

- Both my Speed Stick Original Scent and Old Spice High Endurance Original contain no Aluminum. They are both deodorants, NOT antiperspirants, which work differently. Deodorants do not inhibit sweating, they just keep you from smelling funky from it. Hence the name DEodorant. Antiperspirants on the other hand DO inhibit sweating as well as keep you smelling fresh. They do so by clogging your pores! And if there is aluminum in it, it can cause irritation on some people. Most antiperspirants contain aluminum, most deodorants do not. Whichever you end up going with just read the back label.

Send your message to us

Menards Aluminum Coil Stock for Colored Foil Rolls of Hairdressing Aluminium

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 box

- Supply Capability:

- 300000 box/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords