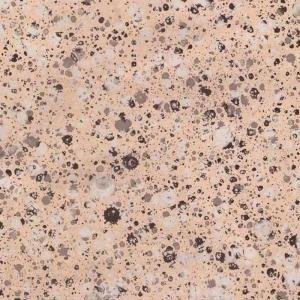

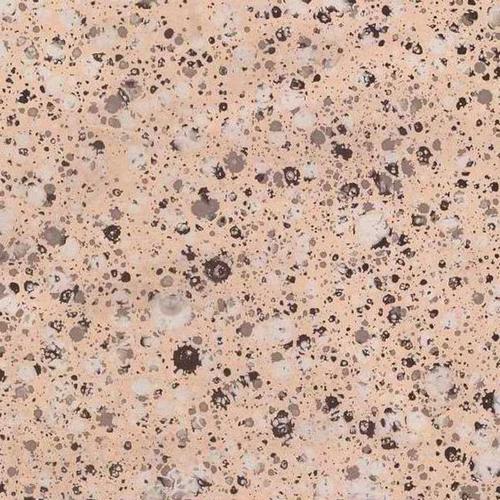

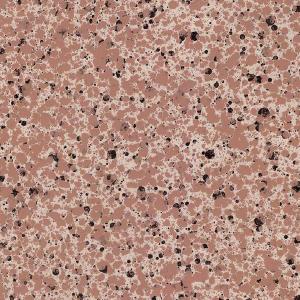

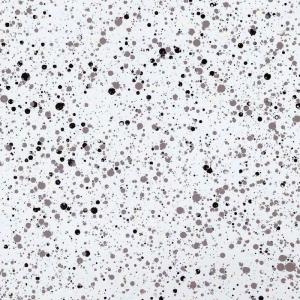

024 Aluminum Coil with Marble Grain Coating

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium coated sheetand coil choose aluminium sheet coil as raw material, after de-ester, cleaning,passivation layer processing, and then painting on this basis, the paint areprovided by famous international companies like PPG and Valspar from UnitedStates or Becker from Sweden, represent the most advanced level in the world.After the test of exposure by natural light in Florida, the quality assurance is more than morethan 20 years. As poor performance of color coated steel corrosion, rust,yellow rust after a large amount of the deficiency of serious impact on thebuilding's overall appearance. However, because of the advantages of rawmaterials, Aluminium coated coil have a high strength, corrosion resistance,high weather resistance, can be used recycle, save energy and protect theenvironment and other characteristics. Not only have the same strength with colorcoated steel, but also overcome the shortage of color coated steel. So, the Aluminiumcoated coil has been widely used as roofing and ceiling decorative envelopesystem board in modern constructions like large factories, exhibition halls,stadiums, airports, train station hospital and so on. We can choose Aluminiumcoated coil in different thickness and color, by cutting, pressing, punching,bending and other follow-up molding process for large span, the larger theoverall roofing, wall decorative panels used in construction; or cut them intosmall panels by bending, stamping mold or other processing for indoordecorative roofing plate; we can also composite them with polyurethane foam oraluminium honeycomb for energy-saving decorative wall plates.

Alloy | 1050,1060,1100,3003,3004,3005,3104,3105,5052,5005,8011 |

Temper | O,H42,H44,H46,H48 |

Thickness (mm) | 0.25mm-1.5mm for aluminium coated coil; 1.50mm-4.0mm for aluminium coated sheet. |

Width (mm) | 100mm to 2000mm |

Length (mm) | 800mm to 6000mm for sheet |

- Q: Is it safe and practical to utilize aluminum coils for food storage purposes?

- <p>Aluminum coils can be used for storing food, but it's important to consider the type of food and the conditions. Aluminum is a good conductor of heat, making it suitable for cooking and preserving food in certain contexts, such as in foil form for wrapping food for baking or grilling. However, for long-term storage, especially of acidic or alkaline foods, aluminum may not be ideal due to potential leaching of aluminum into the food, which could be harmful. It's also crucial to ensure that the aluminum is food-grade and not contaminated with harmful substances. For most food storage needs, other materials like glass, stainless steel, or food-grade plastic are often preferred due to their non-reactive nature and safety.</p>

- Q: is Aluminum wrotten with a 2 behnd it?

- No. Aluminum is a metal, which means that its structure is essentially a lattice of metal cations with very loosely-held electrons passing rather freely between them.

- Q: Are aluminum coils resistant to mold and mildew?

- Yes, aluminum coils are highly resistant to mold and mildew. Aluminum does not provide a favorable environment for mold or mildew growth, making it an excellent choice for applications where moisture and humidity are concerns.

- Q: Can aluminum coils be used in marine applications?

- Yes, aluminum coils can be used in marine applications. Aluminum is a corrosion-resistant metal that provides excellent durability and strength, making it suitable for various marine environments. It is commonly used in boat building, marine equipment, and other marine applications due to its lightweight nature and resistance to saltwater corrosion.

- Q: How are aluminum coils tested for thickness and flatness?

- Various methods are employed to test aluminum coils for thickness and flatness, ensuring they meet the necessary specifications. One commonly used method is non-destructive eddy current testing. This involves passing an alternating current through the coil and measuring the changes in the magnetic field caused by the eddy currents induced in the aluminum. By analyzing these changes, the thickness of the coil can be determined. Ultrasonic testing is also utilized to measure the thickness of aluminum coils. This method involves sending ultrasonic waves through the coil and measuring the time it takes for the waves to bounce back. It is highly accurate and capable of identifying any variations in thickness throughout the entire coil. To assess the flatness of aluminum coils, a straight edge or laser beam is often employed. The coil is placed on a flat surface, and the straight edge or laser beam is positioned across its surface. Any deviations from perfect flatness can be easily identified by observing the gaps or irregularities between the coil and the straight edge or laser beam. For a more comprehensive analysis of flatness, advanced technologies like laser profilometry can be used. This involves creating a three-dimensional map of the coil's surface, providing highly detailed information about any variations in flatness across its surface. In conclusion, aluminum coils are subjected to rigorous testing procedures to ensure they meet the necessary standards for thickness and flatness. These tests are essential in maintaining the quality and reliability of aluminum coils, particularly in applications where precision and consistency are crucial.

- Q: Hi,I am fairly new to design and have been doing technical drawing for only a few months. We have an item, that supports up to about 800KG of weight, as a C shaped channel. We are currently making this out of 3mm Mild Steel. Due to a new design, we are changing this design to avoid welding and painting the above part. This means we will be making the part from Galv sheet.I would like to make the part from Aluminium because 1) There will be no rust, 2) I think it will look better than Galv sheet but I need to keep the cost down.We use 3mm mild at the moment, because it is easier to weld than 2mm, not for strength really.Therefore, my question is, in everybody's opinion, would it be OK to make it from 2mm Aluminium, or is this likly to end in disaster?FYI, the part is 1600mm long, then on each long side there are presses of up 250mm, down 80mm and down 20mm. The weight is supported at 4 points on the 80mm flanges.What a question for my first go Answers! TIA

- Which has better songs - Number Of the Beast Which has better riffs - British Steel Which has better solos - Number of The Beast Which has better vocals - Number of the Beast Which has a cooler cover - Number of the Beast Which do You prefer - This is a real thinker, almost like Sophies Choice Metal edition. But I have owned Number and the Beast longer than I have owned British Steel. So I go with Iron Maiden Both albums get a perfect 10 because they deserve it, both have great musicianship and both have great vocals

- Q: Why does the coated aluminum coil have thickness requirement for membrane?

- The purpose of coating is to protect the surface of aluminum coil and make it more aesthetic. The thickness of membrane is closely related to the keep years of products made by aluminum coil.

- Q: Can aluminum coils be used in food packaging?

- Yes, aluminum coils can be used in food packaging. Aluminum is a safe and versatile material that has been widely used in the food packaging industry for many years. It offers various benefits such as being lightweight, resistant to corrosion, and having excellent thermal conductivity. These properties make it ideal for food packaging applications where it is important to preserve the quality, freshness, and safety of the food products. Aluminum coils can be easily formed into different shapes and sizes, allowing for customized packaging solutions. Additionally, aluminum is a sustainable material as it is 100% recyclable, which further enhances its appeal for food packaging.

- Q: What are the different coil packaging materials used for aluminum coils?

- Some common coil packaging materials used for aluminum coils include wooden pallets, steel strapping, stretch film, and cardboard edge protectors.

- Q: Explain how the temperature affects aluminum coil properties and behavior.

- <p>The relationship between aluminum coil and temperature is significant as temperature influences the coil's physical properties and performance. At lower temperatures, aluminum coils become more brittle and susceptible to cracking or breaking. As the temperature increases, aluminum's ductility improves, allowing it to be more easily shaped and formed. However, excessive heat can also lead to deformation and loss of strength. The thermal conductivity of aluminum is high, meaning it conducts heat well, which is useful in applications requiring heat transfer. Additionally, the electrical conductivity of aluminum is affected by temperature; as temperature rises, resistance increases, which can impact applications where electrical conductivity is critical.</p>

Send your message to us

024 Aluminum Coil with Marble Grain Coating

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords