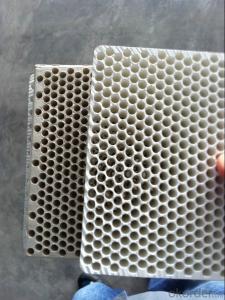

Alumina Ceramic Rod Ceramic Filter Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

alumina ceramic parts

1.Material: High purity alumina

2.Processed by cold-pressing

3.QA,rush delivery

4.MOQ:500pcs

Name | Unit | Alumina | Zirconia | ||

Content | % | ≥95 | ≥99 | ≥99.7 | ≥94 |

Density | g/cm3 | 3.60 | 3.90 | 3.90 | 6.00 |

Hardness (Hv0.5) | GPa | 13.1 | 15.0 | 17.1 | 13.2 |

flexural strength

| MPa≥ | 340 | 310 | 370 | 1000 |

Elasticity | GPa | 300 | 330 | 350 | 200 |

Poisson's ratio

|

| 0.23 | 0.23 | 0.23 | 0.30 |

Max Tem. | °C≥ | 1400 | 1750 | 1800 | 1050 |

Heat expansion | ×10-6/°C(40-800°C) | 7.8 | 8.0 | 8.0 | 11.0 |

Thermo conductivity

| W/m·K( 20°C) | 22 | 28 | 31 | 2.6 |

Thermal Resistance | °C | 200 | 200 | 230 | 300 |

dielectric strength

| V/m | 15×106 | 15×106 | 15×106 | 11×106 |

dielectric phase angle (1MHz) | ×10-4 | 4 | 2 | 1 | 16 |

SIC(1MHz) |

| 9.2 | 9.8 | 9.9 | 33 |

Nitric Acid (60%)90°C | WT Loss mg/cm2/day≤ | 0.12 | 0.10 | 0.05 | ≠0 |

Sodium hudroxide (30%)80°C | WT Loss mg/cm2/day≤ | 0.53 | 0.26 | 0.04 | 0.08 |

- Q: Performance advantages of ceramic filter

- The base is provided with a slime recovery rotor, the rotor consists of a shaft, multistage ceramic filter disc, stripper plate, multi section water connecting pipe, pipe support plate, negative pressure connecting component dynamic disk; the rotor is in the recovery of coal slime liquid tank; the ceramic filter disc by a plurality of ceramic microporous plate cavity, located on the same axis of a ceramic plate cavity communicated through the outlet connection pipe.

- Q: Why should filter core be used in backwash of ceramic filter?

- The filter in the water filter of ceramic filter is used for filtering water.

- Q: Ceramic filter in vacuum pressure enough, the ceramic plate does not suck pulp, what is the reason for analysis?

- The filtrate is not discharged smoothly.The filtrate can not be discharged in a timely and smooth manner, the new filtrate can not be sucked out, and the filtrate can not be continuously sucked out, so that the filter cake can not be adsorbed on the ceramic plate.

- Q: What's the reason for high water content in filtration copper concentrate?

- Vacuum: about -0.08MPaIf the vacuum required to consider other factors; such as the vacuum degree is not up to even only about -0.05MPa, it should be related to pipeline inspection of vacuum system leakage, vacuum pump damage, distribution valve failure, ceramic plate breakage, ceramic plate connecting pipe leakage may cause the vacuum is not up to, to achieve early detection and early treatment.

- Q: What are the materials that make up the ceramic mold?

- Ceramic membrane, also known as CT film, is one of the solid membrane, the earliest by Japan's large Japanese printing company and Toyo ink company in 1996, the introduction of the market. The ceramic coating is mainly A12O3, Zr02, Ti02 and Si02 of inorganic materials such as porous membrane preparation, the pore size of 250mm. Has good chemical stability, acid resistance, alkali resistance, solvent resistance, high mechanical strength, can reverse flushing: anti microbial ability: high temperature, narrow pore size distribution, higher separation efficiency characteristics, has been widely used in food industry, biological engineering, environmental engineering, chemical industry, petroleum chemical industry, metallurgy industry etc. The market sales, with an annual growth rate of 35% growth. Compared with plastic products of ceramic membrane with similar high cost, but also has many advantages, it is hard to withstand strong, durable, not easy to have chemical resistance village, invasive and high temperature liquid cleaning liquid has a stronger ability to resist, its main drawback is the price expensive. _ complex manufacturing process

- Q: Principle of chemical engineering drum vacuum filter, the faster the speed, the less the amount of filtrate obtained per turn, the more the amount of filtrate obtained per unit time?

- In unit time, the more turns of the drum, the greater the centrifugal force, the greater the rate of filtration in unit time, that is to say, the amount of filtrate in unit time is moreRotating drum vacuum filter, the greater the speed, the greater the filtration rate, but the shorter the time each turn, the amount of each filtrate will be reduced

- Q: Can the plate filter press pass through the filter plate?

- There are many types of pumps to be used, such as screw pumps, slag pumps, rotary pumps, piston pumps, and diaphragm pumps.

- Q: Ceramic filter fineness thin mud suction is not what to do more

- With ceramic filter to treat pulp dehydration, the particle size is too large, the particles are easy to precipitate, the particle size is too small, too much mud, then the water content of the filter cake will increase, and the life of the ceramic filter plate will be reduced.

- Q: Ceramic filter ceramic plate blockage, productivity reduction, how to clean, to achieve the best effect cleaning problems

- Selection of new ceramic filter plate:Because of the different size and characteristics of the pulp, different users need ceramic filter plates with different pore sizes (i.e., the average range of their surface pore size). In order to avoid the possibility of plugging, ceramic filter plates with suitable aperture range of different manufacturers can be selected.

- Q: How can I avoid the backwash pressure in the production of ceramic filter?

- Recoil of the ceramic filter is on the clean water under certain pressure, from the inside out flushing blockage blockage in the ceramic filter plate on the internal pore water pressure, the recoil is generally less than 0.12MPa, the pressure is too small or no recoil recoil effect is not good.

Send your message to us

Alumina Ceramic Rod Ceramic Filter Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords