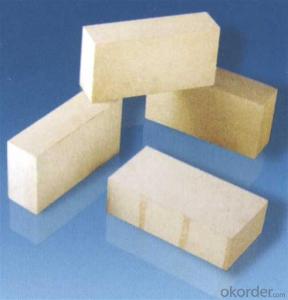

Alumina Bubble Insulating Fire Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

General Information

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

Feature

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Application

CMAX insulating firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass.

- Q: Can insulating fire bricks be used in the construction of hot blast stoves?

- Yes, insulating fire bricks can be used in the construction of hot blast stoves. Insulating fire bricks are designed to withstand high temperatures and provide excellent thermal insulation, making them suitable for use in environments with extreme heat such as hot blast stoves. These bricks help to maintain the high temperatures required for efficient combustion while minimizing heat loss, improving the overall performance and energy efficiency of the hot blast stoves.

- Q: What is the recommended curing time for insulating fire bricks?

- The recommended curing time for insulating fire bricks varies depending on the manufacturer and specific product. It is typically recommended to follow the curing instructions provided by the manufacturer, which can range from a few hours to several days.

- Q: Can insulating fire bricks be used in fireplaces?

- Yes, insulating fire bricks can be used in fireplaces. They are designed to withstand high temperatures and provide excellent insulation, making them suitable for lining the inside of fireplaces.

- Q: Can insulating fire bricks be used in ladles and tundishes?

- Yes, insulating fire bricks can be used in ladles and tundishes. Insulating fire bricks are designed to withstand high temperatures, making them suitable for use in these refractory applications. They provide excellent thermal insulation, reducing heat loss and improving energy efficiency in ladles and tundishes.

- Q: How does an insulating fire brick work?

- Insulating fire bricks, which are also referred to as refractory bricks, serve as thermal barriers in various industrial applications and are designed to withstand high temperatures. These bricks are made from refractory materials that possess low thermal conductivity, indicating their poor heat conduction abilities. The primary mechanism employed by insulating fire bricks revolves around their capability to hinder and slow down heat transfer. Unlike regular bricks or concrete, insulating fire bricks possess a significant number of air pockets within their structure, which act as insulators. These air pockets effectively obstruct the movement of thermal energy, preventing heat transfer. When exposed to high temperatures, insulating fire bricks absorb minimal amounts of heat due to their low thermal conductivity. Rather than conducting heat through the brick, the energy is either absorbed or reflected by the air pockets present in the brick's structure. As a result, heat is unable to permeate to the other side of the brick, effectively creating a thermal barrier. Moreover, the refractory materials utilized in insulating fire bricks inherently possess resistance against thermal shock, enabling them to endure rapid temperature changes without cracking or breaking. This quality makes them exceptionally suitable for applications where extreme temperature fluctuations occur frequently. Insulating fire bricks find extensive usage in industries such as metallurgy, ceramics, glass manufacturing, and kiln construction. They are primarily used to line furnaces, kilns, and other equipment operating at high temperatures. By effectively reducing heat transfer, these bricks contribute to enhancing energy efficiency, minimizing heat loss, and safeguarding surrounding materials and structures from the extreme levels of heat. In summary, the operational principle of an insulating fire brick lies in its ability to minimize heat transfer by virtue of its low thermal conductivity and air pocket structure. By establishing a thermal barrier, these bricks fulfill a critical role in providing insulation, protecting against heat loss, and ensuring the smooth functioning of high-temperature processes.

- Q: Can insulating fire bricks be used in DIY projects?

- Certainly, DIY projects can make use of insulating fire bricks. With their lightweight and superb thermal insulation properties, these bricks prove suitable for a range of applications. They find common use in the construction of wood-fired ovens, fire pits, kilns, and even forge walls. Insulating fire bricks possess the ability to endure high temperatures and resist thermal shock, thus providing a dependable option for heat-resistant structures crafted by DIY enthusiasts. Furthermore, they offer ease of cutting and shaping, enabling customization to align with specific project requirements.

- Q: Can insulating fire bricks be used in incinerators?

- Yes, insulating fire bricks can be used in incinerators. They are designed to withstand high temperatures and provide excellent insulation, making them suitable for use in the intense heat of incinerator systems.

- Q: Can insulating fire bricks be recycled or reused?

- Yes, insulating fire bricks can be recycled or reused. Insulating fire bricks are made from various materials such as alumina, silica, and clay, which can be broken down and reused in the production of new bricks. Recycling these bricks involves crushing them into a fine powder and then mixing it with other raw materials to create new bricks. Reusing insulating fire bricks is also possible in certain applications. For example, if the bricks are still in good condition and have not been damaged, they can be removed from one structure and used in another. This reduces waste and saves resources. Overall, whether through recycling or reusing, insulating fire bricks can have a second life and contribute to a more sustainable and environmentally-friendly construction industry.

- Q: Are insulating fire bricks resistant to chemicals?

- Yes, insulating fire bricks are generally resistant to chemicals. They are designed to withstand high temperatures and have low thermal conductivity, making them an ideal choice for applications involving chemicals. These bricks are typically made from ceramic materials, such as alumina, which has excellent chemical resistance properties. However, it is important to note that the degree of chemical resistance can vary depending on the specific type of insulating fire brick and the chemicals involved. Some chemicals, especially highly corrosive or reactive ones, may still cause damage or degradation to the bricks over time. Therefore, it is advisable to consult the manufacturer or supplier for detailed information on the chemical resistance capabilities of specific insulating fire bricks.

- Q: Can insulating fire bricks be used for pizza ovens?

- Indeed, pizza ovens can make use of insulating fire bricks. These bricks have been specifically crafted to endure extreme heat and offer exceptional insulation, positioning them as an optimal selection for pizza ovens. By possessing low thermal conductivity, insulating fire bricks excel at retaining heat for extended durations, guaranteeing that your pizza is evenly and efficiently cooked. Moreover, their lightweight composition allows for effortless handling and installation in a pizza oven. Ultimately, the utilization of insulating fire bricks within a pizza oven can effectively uphold high temperatures, diminish heat loss, and enhance the overall cooking proficiency.

Send your message to us

Alumina Bubble Insulating Fire Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords