Ultra High Temperature Insulating Fire Brick - Alumina Bubble Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Thermal Insulation Fire Clay Brick

CNBM conforms strictly to the requirements of ISO 9000 quality control system during the production. MSDS is also available if you want. The thermal insulation fire clay brick meet with the requirements of ASTM & JIS standards. So please stay cool with our quality.

Application

Insulating Fire Brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

(4)Flexible payment: T/T L/C D/P D/A

(5)Professional marketing team and after-sale service

(6)Free sample

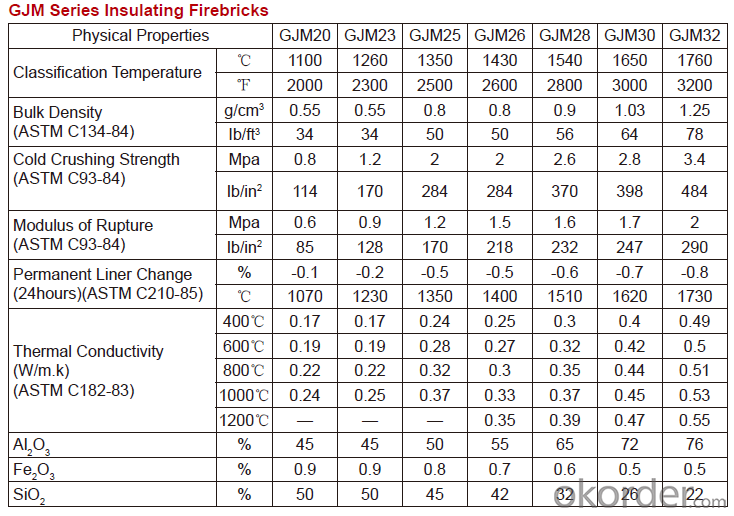

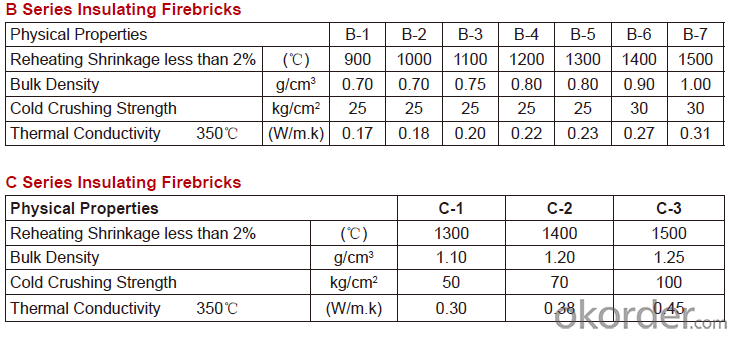

Insulating Fire Brick main feature:

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

2 units of Compact grain Abrasive pilot production lines

1 unit of high-end coated abrasives (abrasive cloth) production line

2 units of Boron Carbide production lines

3 large flexible crushing and sieving lines for grit production lines

2 units of 2000KVA furnaces for Boron Carbide fusion

6 units of 5000KVA-10000KVA dumping type electric arc furnaces for Brown Fused Alumina fusion

FAQs

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Can insulating fire bricks be used as insulation in walls and roofs?

- Yes, insulating fire bricks can be used as insulation in walls and roofs. They have excellent thermal insulation properties, high heat resistance, and are specifically designed for use in high-temperature environments.

- Q: Are insulating fire bricks suitable for high-temperature kilns?

- Yes, insulating fire bricks are suitable for high-temperature kilns. They are specifically designed to withstand extreme temperatures, making them an ideal choice for insulation in kilns. These bricks are made from lightweight refractory materials that have excellent thermal conductivity properties, allowing them to effectively retain heat and minimize heat loss. Additionally, insulating fire bricks have high resistance to thermal shock, ensuring their durability and longevity in high-temperature environments.

- Q: Can insulating fire bricks be used in the construction of industrial chimneys?

- Indeed, insulating fire bricks are capable of being utilized in the construction of industrial chimneys. These bricks are meticulously crafted with exceptional thermal insulation properties, rendering them perfectly suited for situations where precise temperature management is paramount. Given that industrial chimneys endure elevated temperatures and heat transmission, insulating fire bricks prove invaluable in mitigating heat dissipation or acquisition, thereby enhancing energy efficiency and minimizing the likelihood of structural harm. Furthermore, these bricks exhibit commendable resilience against thermal shock, enabling them to endure the rigorous conditions commonly encountered in industrial environments. Consequently, insulating fire bricks emerge as a fitting choice for constructing industrial chimneys.

- Q: Can insulating fire bricks be used as a lining material for boilers?

- Yes, insulating fire bricks can be used as a lining material for boilers. Insulating fire bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for use in boiler linings.

- Q: Is it necessary to abolish the technical regulations for the construction of self thermal insulation masonry building with sludge sintering insulation bricks?

- The original "technical specification for self insulation masonry building with silt insulation bricks" has been replaced by DGJ32/TJ78-2009 (technical specification for automatic insulation wall system of sintered silt non bearing insulating brick) DGJ32/TJ78-2013.

- Q: Do insulating fire bricks have a high insulation efficiency?

- Yes, insulating fire bricks have a high insulation efficiency. Due to their low thermal conductivity and high heat resistance, they effectively prevent the transfer of heat, thereby providing excellent insulation.

- Q: Can insulating fire bricks be used in the construction of glass melting tanks?

- Yes, insulating fire bricks can be used in the construction of glass melting tanks. Insulating fire bricks are specifically designed to withstand high temperatures and provide excellent insulation properties. This makes them ideal for use in glass melting tanks, where extreme temperatures are required to melt the glass. The insulating properties of these bricks help to minimize heat loss and maintain the desired temperature within the tank, resulting in more efficient and cost-effective glass melting processes. Additionally, insulating fire bricks are durable and resistant to thermal shock, making them a reliable choice for the construction of glass melting tanks.

- Q: The difference between ordinary and diatomite brick refractory brick

- Refractory brick belongs to a large class, according to different materials used are divided into: high alumina brick, dolomite brick, magnesia chrome brick, magnesia spinel brick, phosphate brick, carborundum brick, brick, mullite bricks etc..

- Q: Are insulating fire bricks suitable for use in wood-fired ovens?

- Indeed, insulating fire bricks are appropriate for utilization in wood-fired ovens. These bricks have been meticulously crafted to endure extreme temperatures, rendering them exceptionally suitable for deployment in ovens or other heat-intensive scenarios. Insulating fire bricks boast exceptional thermal insulation properties, aiding in the preservation of heat within the oven and guaranteeing a more effective cooking procedure. Moreover, these bricks exhibit low thermal conductivity, signifying that they transmit less heat to the external surfaces, resulting in a cooking experience that is both safer and more comfortable. Consequently, the utilization of insulating fire bricks in wood-fired ovens can yield superior heat retention, enhanced energy efficiency, and an overall improved performance.

- Q: Can insulating fire bricks be used in the construction of industrial furnaces?

- Yes, insulating fire bricks can be used in the construction of industrial furnaces. Insulating fire bricks are specifically designed to withstand high temperatures and thermal shocks, making them suitable for use in furnaces where temperatures can reach extremely high levels. These bricks have low thermal conductivity, which helps to minimize heat loss and improve energy efficiency in the furnace. Additionally, insulating fire bricks are lightweight and easy to handle, making them convenient for construction purposes. Overall, their excellent insulation and heat-resistant properties make insulating fire bricks an ideal choice for industrial furnace construction.

Send your message to us

Ultra High Temperature Insulating Fire Brick - Alumina Bubble Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords