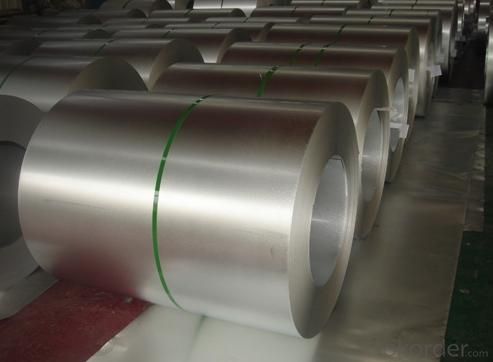

Alu-Zinc Galvalume Steel Coils/Plate SGCC Gi Gx51d

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Details

Basic Info.

Type:Steel Plate

Standard:ASTM, AISI, GB, JIS, DIN, BS

Certification:ISO, SGS, BV, RoHS, IBR

Surface Treatment:Galvalume

Technique:Hot Rolled & Cold Rolled

Application:Ship Plate, Boiler Plate, Container Plate, Flange Plate

Special Use:Carbon Steel

Stock:Not Stock

Thick:0.12-4.0mm

Width:600-1250mm

Zinc Coating:Az50-Az150G/M2

Material:Dx51d,Dx52D,G350-G550

Surface:Anti-Fingerprint,Minimumed Spangle ,Bright , Oiled

Export Markets:Global

Additional Info.

Trademark:Sino Steel

Packing:Properly Packed for Ocean Freight Exportation

Standard:SGS, ISO9001

Origin:Shandong

HS Code:721061000

Production Capacity:350000 Tons/Year.

Product Description

Hot Dipped 55% Aluminum Zinc Alloy Coated Steel by the Hot-Dip Process

Hot Dip Galvalume steel coil EN 10327 JIS G3321, ASTM A792M 55% AL-ZN coated

Specification:

| Commodity | AZ150 AFP G550 Galvalume steel coil with SGS certification |

| Technical Standard: | JIS,GB,DIN,BS,ASTM |

| Grade | DX51D / DX52D/ DX53D/G300/G550 |

| Types: | Commercial / Drawing / Deep Drawing / Structural quality |

| Width | 500/650/726/820/914/1000/1200/1219/1220/1250mm |

| Thickness | 0.12-4mm |

| Type of coating: | aluminum-zinc alloy |

| Zinc coating | AZ50-AZ150 55% Al, 43.5%Zn, 1.5%Si. |

| Surface treatment | Pre-painted/ skin pass/ oiled/slightly oiled/unoiled/ dry/ anti-fingerprint/Non anti-fingerprint |

| Surface structure: | minimized spangle / regular spangle |

| ID coil | 508mm or 610mm |

| Coil weight | 3-8 MT per coil/ sheet will be cut as clients's requirments |

| Package: | Properly packed for ocean freight exportation in 20''containers |

| Application: | Industrial panels, roofing and siding for painting |

| Price terms | FOB,CFR,CIF,CNF,DAP,etc |

| Payment terms | 30%TT deposit in advance +70% TT balance against copy of B/L or irrevocable 70% L/C at sight |

| delivery time | Within 25 work days after deposit received. |

| Remarks | Insurance is all risks |

| MTC will be handed on with shipping documents | |

| Third party inspection such as SGS supported |

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

4.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

- Q: did bible stated that steel is coming from outer space. i mean meteor rocks that enter our earth sistem contains the minerals iron.

- If you are using either an NAB or RSV translation of the Bible, steel is only mentioned once in the Bible. Compare Nahum 2:4 (NAB) and Sirach 31:26 (RSV). There is no reference of an outer space in the Bible. Furnace is mentioned in Sirach. It takes a lot of energy to mix Iron and Carbon to produce steel. The alloy can only be produced in the furnace at an extremely high temperature.

- Q: How do steel coil manufacturers ensure employee safety?

- Steel coil manufacturers ensure employee safety through a combination of safety training programs, implementation of safety procedures and protocols, regular equipment maintenance, and providing personal protective equipment. They also conduct regular safety audits and inspections to identify and address any potential hazards in the workplace.

- Q: is cold roll or hot roll mill roller is cast steel? or cast iron?

- Casting is a process of forming a part just like forging or rolling are also processes of forming steel. Cast steel can be any grade of steel poured into a sand mold to form a part like a water pump housing in your car. To be classified as steel, the mixture usually contains less than 2% carbon. Cast iron is a mixture that generally contains more than 2% carbon. It also can be poured into a sand mold. There are many grades of iron. Many metals can be cast into shapes like the air intake plenum on your car is probably cast aluminum. Bronze statues are made by pouring molten bronze into a mold. The process used to create a part has an effect of that part's mechanical properties. A casting is weaker than a forging but certain parts cannot be formed by forging. The large diameter rolls used in steel mills to roll steel into thinner plates or sheets is a hot rolled steel that has probably been forged into shape then machined into the final diameter. Some rolls are fabricated from hot rolled steel plates into shape. This allows the ability to add internal cooling paths to keep the roll from overheating.

- Q: which type of carbon steel does not have manganese

- None. Mn is a trace impurity in all steels, if you look carefully enough. If you want to find a steel where Mn is not intentionally added, start looking at the alloy composition specifications, there are hundreds of steels. Why are you worried about Mn? Mn is typically added to steels for a very good reason.

- Q: How do steel coils contribute to the manufacturing of oil and gas equipment?

- Steel coils are an essential component in the manufacturing of oil and gas equipment. These coils are typically made from high-quality steel that is durable, strong, and resistant to corrosion, making them ideal for withstanding the harsh environments and conditions encountered in the oil and gas industry. One of the primary applications of steel coils in oil and gas equipment manufacturing is in the fabrication of pressure vessels. Pressure vessels are crucial components used for storing and transporting various fluids and gases under high pressure. Steel coils are used to form the cylindrical shells of these vessels, providing the necessary strength and structural integrity to withstand the internal pressure. Steel coils are also utilized in the construction of oil and gas pipelines. These pipelines are responsible for transporting vast quantities of oil and gas over long distances. Steel coils are used to manufacture the pipes that make up these pipelines, providing the necessary strength, durability, and resistance to corrosion. The coils are rolled and welded to form seamless or welded pipes, which are then coated or lined to prevent corrosion and enhance their longevity. Furthermore, steel coils are instrumental in the production of drilling equipment used in the extraction of oil and gas. This equipment includes drill bits, casings, and wellheads, which are crucial for drilling and completing wells. The coils are used to fabricate these components, ensuring they can withstand the demanding conditions encountered during drilling operations. In addition to their structural applications, steel coils are also used in the manufacturing of ancillary equipment such as tanks, storage containers, and heat exchangers. These components play a vital role in the processing, storage, and distribution of oil and gas. Steel coils provide the required strength and durability to handle the harsh conditions and corrosive substances encountered in these processes. Overall, steel coils are indispensable in the manufacturing of oil and gas equipment. Their strength, durability, and resistance to corrosion make them a preferred choice in the industry. By contributing to the fabrication of pressure vessels, pipelines, drilling equipment, and ancillary components, steel coils ensure the safe and efficient extraction, processing, and transportation of oil and gas.

- Q: I have a job where I'm required to wear ANSI certified steel toed boots or shoes(so long as its ANSI). Thing is, I'm a vegan. I do NOT want to buy leather, and I will go to great lengths to buy a non leather shoe/boot I can wear on the job! I AM currently borrowing my dad's leather ANSI boots, but would very much love to be able to rock a pair of cruelty free boots/shoes on the job!It does not have to be certified vegan just all man-made materials and no leather/sued and other such stuff where animals have to die. It would make me no better than the massive slaughterhouse industries and such. Valueing money of ver live/morals. I don't want one of the first things I need to do in my manufacturing job is compromising my morals. :3So if you know of an ANSI vegan friendly boot brand PLEASE TELL ME! *gets on knees begging*Money isn't really an option for me, I'll just continue borrowing my dad's boots till I save up enough!Thanks in advance! :D

- This Site Might Help You. RE: Vegan ANSI Steel Toes? I have a job where I'm required to wear ANSI certified steel toed boots or shoes(so long as its ANSI). Thing is, I'm a vegan. I do NOT want to buy leather, and I will go to great lengths to buy a non leather shoe/boot I can wear on the job! I AM currently borrowing my dad's leather ANSI...

- Q: How are steel coils tested for strength?

- Steel coils are tested for strength using a variety of methods such as tensile testing, hardness testing, and impact testing. Tensile testing involves applying a controlled force to the coil until it breaks, measuring the amount of force required to rupture the steel. Hardness testing measures the resistance of the steel to indentation or scratching, providing an indication of its strength. Impact testing evaluates the ability of the steel to absorb energy under sudden loading conditions. These tests help determine the overall strength and quality of the steel coils.

- Q: okay i got some questions of the steel plow.1st - who inveneted it? where and when?2nd - how did it work? what is it used for? what is it made of? how is it produced?okay guys thank you very much. remember best answer gets best answer 10 points!

- If you're willing to substitute the word iron for steel (steel came a good bit later in history), the Girard plow from the 1300's in Belgium would be the first example known. It's named after the guy who invented it (Girard). How did it work? Like any other plow! You drag it along and it makes a trench of sorts in the ground! It was used for agricultural purposes. As for how it was produced, you need to look up the history of the Iron Age to understand how they started to use iron back in about 1200BC to make tools.

- Q: How are steel coils used in the manufacturing of doors and windows?

- Steel coils are used in the manufacturing of doors and windows as they provide a strong and durable material for constructing the frames and components. The coils are first processed and cut into the desired shape, then formed and welded together to create the frames. This ensures stability and support, allowing the doors and windows to withstand various weather conditions and provide long-lasting performance.

Send your message to us

Alu-Zinc Galvalume Steel Coils/Plate SGCC Gi Gx51d

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords