Aluminum Alu Product for Figure

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

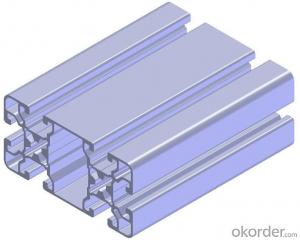

Aluminium alloys with a wide range of properties are used in engineering structures. Alloy systems are classified by a number system (ANSI) or by names indicating their main alloying constituents (DIN and ISO).

The strength and durability of aluminium alloys vary widely, not only as a result of the components of the specific alloy, but also as a result of heat treatments and manufacturing processes. A lack of knowledge of these aspects has from time to time led to improperly designed structures and gained aluminium a bad reputation.

One important structural limitation of aluminium alloys is their fatigue strength. Unlike steels, aluminium alloys have no well-defined fatigue limit, meaning that fatigue failure eventually occurs, under even very small cyclic loadings. This implies that engineers must assess these loads and design for a fixed life rather than an infinite life.

Another important property of aluminium alloys is their sensitivity to heat. Workshop procedures involving heating are complicated by the fact that aluminium, unlike steel, melts without first glowing red. Forming operations where a blow torch is used therefore require some expertise, since no visual signs reveal how close the material is to melting. Aluminium alloys, like all structural alloys, also are subject to internal stresses following heating operations such as welding and casting. The problem with aluminium alloys in this regard is their low melting point, which make them more susceptible to distortions from thermally induced stress relief. Controlled stress relief can be done during manufacturing by heat-treating the parts in an oven, followed by gradual cooling—in effect annealing the stresses.

The low melting point of aluminium alloys has not precluded their use in rocketry; even for use in constructing combustion chambers where gases can reach 3500 K. The Agena upper stage engine used a regeneratively cooled aluminium design for some parts of the nozzle, including the thermally critical throat region.

Another alloy of some value is aluminium bronze (Cu-Al alloy).

Aluminium foil acts as a total barrier to light and oxygen (which cause fats to oxidise or become rancid), odours and flavours, moistness, and germs, it is used broadly in food and pharmaceutical packaging. The purpose of aluminium is to make long-life packs (aseptic processing|aseptic packaging) for drinks and dairy goods, which allows storing without refrigeration. Aluminium foil containers and trays are used to bake pies and to pack takeaway meals, ready snacks and long life pet foods.

Aluminium foil is widely sold into the consumer market, often in rolls of 500 mm (20 in) width and several metres in length.It is used for wrapping food in order to preserve it, for example, when storing leftover food in a refrigerator (where it serves the additional purpose of preventing odour exchange), when taking sandwiches on a journey, or when selling some kinds of take-away or fast food. Tex-Mex restaurants in the United States, for example, typically provide take-away burritos wrapped in aluminium foil.

Aluminium foils thicker than 25 μm (1 mil) are impermeable to oxygen and water. Foils thinner than this become slightly permeable due to minute pinholes caused by the production process.

- Q: What thick ness of metal will 223 round NOT go through?

- Cane toad is right: Without more information12 feet is a safe betEnough rounds and a week enough metal and it is just a matter of time before something goes throughAs Ink said, the type of metal maks a huge differenceAs does the round, distance it was fired from and how many rounds are fired To give an example: If someone went to town on block of aluminum with an M249 and green tip, they could eventually penetrate a foot thicknessMaybe it would take 1000 rounds (I have not tried it and it depends on accuracy also) but every round would remove a litte more each time until it broke through On the other hand 3/8 of A500 steel can thousands of ball rounds from the same distance before it even starts to show signs of wearOther grades of hardened steel may take ball rounds from 25 yards all day, but get torn up by green tip immediately from that distance, though be able to take green tip from 200 yards no problem.

- Q: Don't say this is a stupid questionI'm really not sure lolIt seems like nothing is made of tin, of my knowledgeThey seem to use aluminum for everything, even the Tin Man's costume was made of aluminumTin foil is now aluminum foilIs it just cheaper to use aluminum than tin, or is tin a limited resource?

- 1-A reflective telescope 2-Refractive 4-Reflective

- Q: do they sell disposable aluminum mini pie pans in stores because I have a project about Aussie culture, and I am making mini meat pies and I was wondering if they sold any.

- nonei heard wool and fleece is best even when its wet it will still keep you warmbut cotton is the WORST fabric to wear!

- Q: What are the potential applications of coil-stucco aluminum coils?

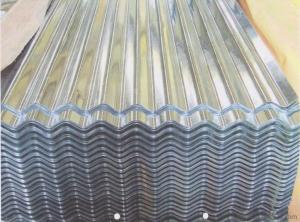

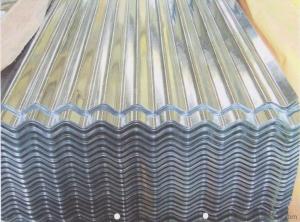

- Coil-stucco aluminum coils have various potential applications due to their unique properties. They are commonly used in the construction industry for roofing, siding, and facades, as their stucco surface provides enhanced durability and weather resistance. These coils are also used in the manufacturing of appliances, such as refrigerators and ovens, as well as in the automotive industry for trim and decorative purposes. Furthermore, coil-stucco aluminum coils can be utilized in the packaging industry for containers and cans due to their lightweight and corrosion-resistant nature.

- Q: what is the mass of 3.45 moles of aluminum sulfate?

- aluminum sulfate is Al2(SO4)3 find the GFM of this 2(27.0) + 3(32.1+(4 * 16.0)) 54.0 + 288.3 342.3grams/mol you have 3.45 moles, so multiply these two numbers 3.45mol x 342.3g/mol = 1180.9g

- Q: concentrated HClwhat will happen if you will perform this procedures? what will happen to the temperature before and after reaction? is this exothermic or endothermic? has it something to do with enthalpy?

- a salt of aluminium choloride will formHeat will be evolved, since it is an ACID-METAL reaction, so it's exothermicThus the tempafter the rxnwill bet greater(hotter) than beforeAll reactions, have to do with enthalpy, lol ;-)

- Q: I don't have many ingredients in my house, but I do have garlic clovesCan I make some with just butter and garlic?

- go to a professional hair salon and ask for their advice on certain brandsbut from past experiences from bad heat damage i used a moisturizer and a heat protector before straighteningthere are also shampoos that can help your hair look better if damaged.

- Q: What is the typical lead time for manufacturing aluminum coils?

- The typical lead time for manufacturing aluminum coils can vary depending on several factors such as the specific requirements of the order, the complexity of the manufacturing process, and the current demand and capacity of the manufacturer. In general, lead times for aluminum coil production can range from a few weeks to several months. For standard aluminum coil orders, where the specifications and quantities are within the manufacturer's regular production capabilities, the lead time is usually shorter and can be around 4-8 weeks. This includes the time required for raw material sourcing, processing, and quality control checks. However, for custom or specialized aluminum coil orders that require specific dimensions, finishes, or additional processing steps such as coating or embossing, the lead time can be longer. These types of orders may require additional time for design and engineering, tooling setup, and testing, which can extend the lead time to approximately 8-12 weeks or more. It is important to note that lead times can also be influenced by external factors such as the availability of raw materials, transportation delays, or unforeseen production issues. Therefore, it is always advisable to communicate with the manufacturer to get an accurate estimate of the lead time for specific aluminum coil orders.

- Q: What is the reflectivity of aluminum coils?

- The reflectivity of aluminum coils is typically high, as aluminum is known for its excellent reflective properties.

- Q: which looks more cooler!? and just to be different..white plastic macbook or aluminum macbook..which one to buy??

- I've got a white one, but it needs to be cleaned a lot. The Mr. Clean magic eraser does the trick when the part where you rest your hands or certain keys start to look grimy. I've just always associated mac/apple with white, so an aluminum one would look weird to me.

Send your message to us

Aluminum Alu Product for Figure

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches