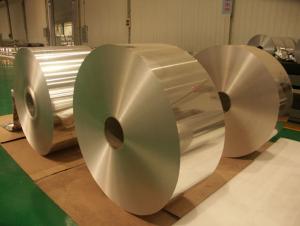

Aluminum Household Foilstock

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 MT m.t.

- Supply Capability:

- 7000MT/MONTH m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick details of Aluminum Foilstock for Household foil

Alloy: 8011

Temper: H14/H16/H24/H26

Specifications of Aluminum Foilstock for Household foil

Thickness & Tolerance: 0.28~0.3mm (±0.01mm)

Width & Tolerance: 1000-2020mm (±1mm)

Standard: GB/T3198 / ASTM-B209 / EN546

Usage/Application of Aluminum Foilstock for Household foil

For for household foil

Packaging & Delivery of Aluminum Foilstock for Household foil

Packing: seaworthy wooden box with pallet

Delivery: to be loaded by 1 x 20 feet container

- Q: Is it possible to recycle aluminum using renewable energy sources such as solar or wind power?

- <p>Yes, aluminum can be recycled using solar energy or wind energy. The recycling process involves melting the aluminum, which can be powered by electricity generated from renewable sources. Solar panels and wind turbines can produce the electricity needed for this process, reducing the carbon footprint associated with aluminum recycling. In fact, recycling aluminum requires only 5% of the energy needed to produce new aluminum from raw materials, making it an energy-efficient process that benefits significantly from renewable energy sources.</p>

- Q: This question asks for methods to effectively clean aluminum surfaces without causing damage.

- <p>To clean aluminum surfaces effectively, use a mild detergent and warm water. Mix a few drops of dish soap with water in a bucket. Dip a soft cloth or sponge into the solution and gently wipe the aluminum surface. Avoid using abrasive materials or harsh chemicals, as they can scratch the surface. After cleaning, rinse with water and dry thoroughly to prevent water spots. For stubborn stains, use a non-abrasive cleaner specifically designed for aluminum. Regular cleaning will help maintain the surface's appearance and prevent corrosion.</p>

- Q: This question asks about the health effects of consuming aluminum on human health.

- <p>Aluminum consumption can have various effects on human health, though the extent of its impact is still a subject of debate among researchers. High levels of aluminum intake have been associated with neurological disorders, particularly Alzheimer's disease, although a direct causal link has not been definitively established. Aluminum can also interfere with bone health, potentially leading to osteoporosis, and may affect the kidneys, causing dysfunction. It is important to note that the human body naturally excretes aluminum, so moderate exposure is generally not harmful. However, excessive intake, especially over a long period, could pose health risks.</p>

- Q: Explain the natural relationship between aluminum and magnesium, focusing on their abundance and reactivity in the Earth's crust.

- <p>Aluminum and magnesium are both abundant elements in the Earth's crust, with aluminum being the most abundant metal and magnesium being the eighth most abundant element overall. They are often found in close association within the same minerals, such as in aluminosilicates and some carbonates. Both elements are highly reactive, forming compounds readily with oxygen to create oxides and silicates. However, they differ in their reactivity with water; aluminum forms a protective oxide layer that prevents further reaction, while magnesium reacts more readily with water to form magnesium hydroxide. This difference in reactivity influences their distribution and the types of compounds they form in nature.</p>

- Q: What is the chemical formula that represents aluminum?

- <p>The chemical formula for aluminum is Al. It is a lightweight, silvery-white metal that is found in the Earth's crust and is the most abundant metal there. Aluminum is a member of the boron group of chemical elements and is represented by the symbol Al, which is derived from the Latin word 'alumen', meaning alum.</p>

- Q: Is it possible to use aluminum as a fuel source?

- <p>Aluminum can be used as a fuel in certain applications, particularly in the form of aluminum powder. It has a high energy density and burns at high temperatures, making it suitable for solid rocket propellants and thermite reactions. However, it is not commonly used as a traditional fuel like gasoline or coal due to its reactivity and the challenges in handling and storage. Aluminum combustion also produces aluminum oxide, which can be harmful to the environment if not managed properly.</p>

- Q: Is it possible to utilize recycled aluminum in the manufacturing of automobiles and other types of vehicles?

- <p>Yes, recycled aluminum can be used to make automobiles and other vehicles. It is a common practice as aluminum is highly recyclable and retains its properties even after multiple recycling processes. Using recycled aluminum reduces the need for new aluminum production, which is energy-intensive, and contributes to sustainability efforts. Recycled aluminum is often used in vehicle components such as engine parts, body panels, and wheels, due to its lightweight, strength, and corrosion resistance.</p>

- Q: Is it possible to enhance the efficiency of solar panels by utilizing aluminum?

- <p>Yes, aluminum can be used to improve the efficiency of solar panels. Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity, which can help in dissipating heat and maintaining optimal operating temperatures for solar cells. It is also used in the manufacturing of solar panel frames, providing structural support while reducing the overall weight of the panels. Additionally, some research suggests that using aluminum in the backsheet of solar panels can enhance their durability and efficiency. However, the extent of efficiency improvement depends on various factors, including the specific design and manufacturing process of the solar panels.</p>

- Q: Is it possible to use pure aluminum for crafting jewelry or sculptures?

- <p>Yes, you can use pure aluminum for jewelry making or sculpture, but it's not as common as other metals due to its lower melting point and softer nature. Pure aluminum is lightweight, affordable, and easy to work with, making it suitable for certain types of designs. However, it's not as durable or resistant to scratches as metals like silver or gold, and it may require special care to maintain its appearance. It's also important to consider the potential for allergic reactions, as some people are sensitive to aluminum.</p>

- Q: Is it possible to utilize aluminum in the creation of innovative tools and equipment?

- <p>Yes, aluminum can be used to make new types of tools and equipment. It is a lightweight, durable, and corrosion-resistant metal, making it ideal for various applications. Aluminum's high strength-to-weight ratio and ease of machinability allow it to be used in the manufacturing of tools, machinery parts, and equipment across industries such as automotive, aerospace, and construction. Additionally, its recyclability and abundance make it an environmentally friendly choice for new tool and equipment designs.</p>

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2000 |

| Annual Output Value | Above US$ 500 Million |

| Main Markets | Mid East; North America; Eur |

| Company Certifications | ISO 14001:2004; FDA |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 30-40 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aluminum Household Foilstock

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 MT m.t.

- Supply Capability:

- 7000MT/MONTH m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords