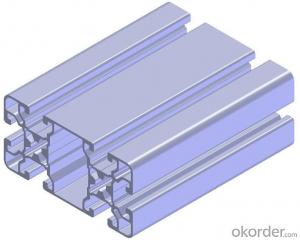

Aluminum Any Use Product

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium alloys with a wide range of properties are used in engineering structures. Alloy systems are classified by a number system (ANSI) or by names indicating their main alloying constituents (DIN and ISO).

The strength and durability of aluminium alloys vary widely, not only as a result of the components of the specific alloy, but also as a result of heat treatments and manufacturing processes. A lack of knowledge of these aspects has from time to time led to improperly designed structures and gained aluminium a bad reputation.

One important structural limitation of aluminium alloys is their fatigue strength. Unlike steels, aluminium alloys have no well-defined fatigue limit, meaning that fatigue failure eventually occurs, under even very small cyclic loadings. This implies that engineers must assess these loads and design for a fixed life rather than an infinite life.

Another important property of aluminium alloys is their sensitivity to heat. Workshop procedures involving heating are complicated by the fact that aluminium, unlike steel, melts without first glowing red. Forming operations where a blow torch is used therefore require some expertise, since no visual signs reveal how close the material is to melting. Aluminium alloys, like all structural alloys, also are subject to internal stresses following heating operations such as welding and casting. The problem with aluminium alloys in this regard is their low melting point, which make them more susceptible to distortions from thermally induced stress relief. Controlled stress relief can be done during manufacturing by heat-treating the parts in an oven, followed by gradual cooling—in effect annealing the stresses.

The low melting point of aluminium alloys has not precluded their use in rocketry; even for use in constructing combustion chambers where gases can reach 3500 K. The Agena upper stage engine used a regeneratively cooled aluminium design for some parts of the nozzle, including the thermally critical throat region.

Another alloy of some value is aluminium bronze (Cu-Al alloy).

Aluminium foil acts as a total barrier to light and oxygen (which cause fats to oxidise or become rancid), odours and flavours, moistness, and germs, it is used broadly in food and pharmaceutical packaging. The purpose of aluminium is to make long-life packs (aseptic processing|aseptic packaging) for drinks and dairy goods, which allows storing without refrigeration. Aluminium foil containers and trays are used to bake pies and to pack takeaway meals, ready snacks and long life pet foods.

Aluminium foil is widely sold into the consumer market, often in rolls of 500 mm (20 in) width and several metres in length.It is used for wrapping food in order to preserve it, for example, when storing leftover food in a refrigerator (where it serves the additional purpose of preventing odour exchange), when taking sandwiches on a journey, or when selling some kinds of take-away or fast food. Tex-Mex restaurants in the United States, for example, typically provide take-away burritos wrapped in aluminium foil.

Aluminium foils thicker than 25 μm (1 mil) are impermeable to oxygen and water. Foils thinner than this become slightly permeable due to minute pinholes caused by the production process.

- Q: what materials can be recycled apart from paper?

- You don't really HAVE to, the skin is kind of thick as far as peppers go, so it makes it more edible ( I love hatch chilis)Also, you are carmelizing sugars and developing flavors by doing this, enhancing the flavorYou can roast the in the oven until the skin blisters and then wrap them and put them in the fridge as usual.

- Q: Ask for advice,According to the type of aluminum alloy, Al-Si, Al-Mg, Al-Mg-Si, Al-Mn, Al-Cu, Al-Zn-Mg (T0-T8 heat treatment); if the steel type crystal like austenite, ferrite, Aluminum Alloy have similar crystal like heat treatment, whether similar to the regulation, for advice! Thank you

- There is no phase change in the process of heating aluminum alloy, so there is no corresponding hard treatment by heat treatment. However, some aluminum parts which are extruded by cold can be softened by heat, but the softening process is more to eliminate the stress without phase change. For these Aluminum Alloy you said, in fact, we often say that the 4XXX series, 6XXX series, 5XXX series aluminum forging, antirust aluminum, 3XXX series, 2XXX series aluminum, aluminum 7XXX series, 7XXX series I've seen can be tempered (just to stress), other if there is no need to do heat treatment, but the aluminum can generally do hard oxidation hardening, but surface hardening, the hardness is not the core.

- Q: thing you did when you were a child?I had this weird(even by my standards today) love of hot potato chips, so one day I took a bag of Cheetos and put it in the microwave The next thing I saw was the bag shrinking and then some small blue lights, so I got scared, turned off the microwave and I took the bag outI threw the bag off the balcony, so no one would know Later, that day, I found out from something I was watching that you're not supposed to put anything metal, or aluminum in the microwave.Man did I feel stupid!That's my story What's yours?

- Try it for a while and seePeople can differ a lot in their tolerance for cold while sleeping, as many a married couple can tell youI myself can tolerate a colder room or lighter covers if I'm wearing socks – even little cotton anklets.

- Q: Why is the US government allowing the space shuttle program to die? We should build 3 new ones with updated materials technology and replace the aging fleetInstead - we're going back to capsules - little round aluminum cans that get shot into space on a the tip of a rocket and then have to parachute back to earth.Parachute.In the 21st century.How can the Orion be used for mass evacuations of the ISS, or carry large crews into space, or carry grouops of high paying tourists into space? Or go out and repair sattelites (like the Hubble last week)?I suggest that every concerned US citixen (and international space exploration enthusiast) get off thier butts and start letting the Whitehouse and Congress know we're not happy - before it's too late.In a couple of years we will be back to 1968 level space exploration.Great.

- I agree with your comments i think the public always thinks there is an easy waythey don't want to pay for anything, but they always expect to get things for freethey are weak in the face of risk (space is all about risk)the fact of the matter is no country or company in the entire world has ever built and operated a shuttle with the capability that the US government and it's private contractors have createdHats off to SpaceShipOne, but it has a long way to go to perform the work of a Space ShuttleThere is no comparisonYou can fault the shuttle program for all it's failuresHowever, the shuttle itself has never failedIt's the launch system that has been problematic(SRBs, Exttank)The shuttles were designed for 100 flightsEven though it's been 20+ yearsThe most any shuttle has flown is about 35The shuttles have a lot more life in themThe shuttles provide capability that no other spacecraft can doWith the shuttles we have 20+ years of knowledge of using the systemWe have a proven systemIt would be a waste of government money to not utilize the shuttles given that they have not even reached the halfway mark in their design lifetimeThe new Orion/Constellation will not be able to perform the work the shuttle canIt is also not a proven systemThere will be setbacksWe should be building upon what we have learned from the Shuttle programNot reinventing the wheel with capsules that land in the waterWe should focus on building a Mars rocket, but there is no need to reinvent the wheel with transporting astronauts to and from earthlet the shuttles do thatWe know how to do it and we have the equipmentit's already paid forThe work those astronauts did repairing the Hubble is exactly the kind of know how our nation needsLet's keep that capabilitywe can use that know-how on the long voyage to Mars.

- Q: What are the different ACP (Aluminum Composite Panel) applications for aluminum coils?

- There are numerous applications for aluminum coils in the production of Aluminum Composite Panels (ACP). ACP is a popular building material due to its lightweight nature, durability, and versatility. Here are some of the different applications for aluminum coils in the ACP industry: 1. Building Cladding: ACP is widely used for building exteriors as cladding material. The aluminum coils are coated with a protective layer and then bonded to a core material, typically made of polyethylene. This combination provides excellent strength, weather resistance, and insulation properties. 2. Signage and Advertising: Aluminum coils are utilized in the production of signage and advertising boards. The panels can be easily cut, bent, and shaped into various designs and sizes, making them ideal for creating eye-catching displays and billboards. 3. Interior Decoration: ACP is commonly employed for interior decoration purposes. It can be used for wall panels, ceiling panels, partitions, and decorative elements. The aluminum coils can be coated with different colors, finishes, and textures to achieve the desired aesthetic appearance. 4. Furniture Manufacturing: Aluminum coils find applications in the production of furniture, particularly for creating lightweight and durable surfaces. ACPs can be used for tabletops, cabinet doors, shelves, and other furniture components. 5. Transportation Industry: Aluminum coils are also utilized in the transportation industry. ACPs can be used for the construction of vehicle bodies, including buses, trucks, and trailers. The lightweight nature of ACPs helps reduce the overall weight of the vehicle, leading to improved fuel efficiency. 6. Industrial Applications: ACPs are widely employed in various industrial applications. They can be used as wall cladding in manufacturing facilities, cleanrooms, warehouses, and other industrial buildings. The panels provide insulation, fire resistance, and easy maintenance, making them suitable for such environments. 7. Renewable Energy Sector: Aluminum coils are used in the production of solar panel frames. ACPs offer exceptional strength and corrosion resistance, making them an ideal choice for providing structural support to solar panels. In summary, aluminum coils are versatile materials that find applications in a wide range of industries for the production of Aluminum Composite Panels. From building cladding to signage, interior decoration, furniture manufacturing, transportation, industrial applications, and renewable energy sector, the uses of ACPs are extensive.

- Q: Explain five the reasons that support statement above.

- Fiber is the indigestible carbohydrates found in unprocessed grains, fruits, vegetables, and some fiber-fortified foodsWhen you eat something with fiber in it, you consume a few fewer calories because your body cannot absorb fiberFoods with fiber also tend to have lower calorie counts, which can help trim your middle, so to speakFiber makes you feel fuller so you can eat less without feeling hungryWhen trying to get more fiber, leave the skins on fruits such as apples, pears, peaches, grapes, etcto get the most fiber and benefitsThe most fiber-rich (and tasty) foods include: Apples (3-8g per serving, depending on size) Pears (4-5g) Kiwi (3g) Blueberries (5g) Raspberries (8g) Strawberries (3-5g) Rye (3-6g) Whole wheat (Wheaties, whole wheat tortillas, etc)(5-8g) Oatmeal (5-8g) Amaranth (5g) Brown rice (2g) Air-popped popcorn (5g) Bran (Up to 14g) Carrots (2g) Baked potato WITH skin (8g) Brocolli (2-4g) Green beans (3-5g) Spinach (3-5g) Bruessel sprouts (3g) Beans (5-8g) Peas (4g)

- Q: I'm cooking today I'm 17 and a family of 7 easy meals cuz I'm just going to publix., no experiments

- The black stuff could be a moisture barrier You can rule out mold by getting a test kit from a hardware store It still could be moldThe drywall might have been replaced after the moisture problem was fixed, but the insulation not replaced There are over 100,000 species of mold, so even if is is mold, it may not be the harmful black mold.

- Q: Can aluminum sheets be used for automotive heat shields?

- Yes, aluminum sheets can be used for automotive heat shields. Aluminum is a lightweight and highly heat-resistant material, making it suitable for shielding the vehicle's components from excessive heat generated by the engine or exhaust system. Its high thermal conductivity helps dissipate heat effectively, making it a popular choice for automotive heat shields.

- Q: Everyone seems to care about the difference in temperature/reflectivity of aluminum foil when used for cooking in the oven, but I want to know about the chemicalsI know the shiny side has more than the dull side, is it irrelevant because there is not enough heat in the oven? Also, if I am temporarily using foil instead of a cookie sheet,does anyone have any experience advice?

- certainly!! My canines do rather foul farts, actual each and every canines i've got ever been close to that has farted has smelled rather undesirableoften i think of they do quiet farts, i haven't heard a noisy one and that i dont think of the intensity of scent has something to do with the dimensions of the caninesi've got had a German Sheperd, a Border Collie, a Kelpie, a Maltese, a Shih Tzu and a Dachsund, all of them do quiet yet stinky fartsOh, they have all had distinctive diets tooadditionally I worked for and were in touch with for the RSPCA for 18 years heard many distinctive canines do their business enterprisenever heard a cat, yet I actual have smelt it! All animals do it, the comparable as us - if it has a bowel, it's going to fartwish that facilitates.

- Q: I had these in for 45 minutes at 450 F and still blood comes outShould be safe to eat? My meat thermometer read off the top.

- Gene H is right on the money with your cooking instructions, and JDB's link gives you the right idea on how it looksHere in Hawaii, we call them musubiI don't ad anything to the rice itself, but we often put stuff inside the center of the musubi Ume, a cherry sized, salty, pickled plum is th most common and traditional, at least for local JapaneseDepending on where you live, Hinode and Diamond G rice are other brands you can look forOther wise look for any rice that is labeled either sushi rice or calrose rice Calrose is a medium grain, Japanese style riceGood luck with your project.

Send your message to us

Aluminum Any Use Product

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches