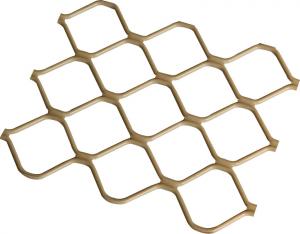

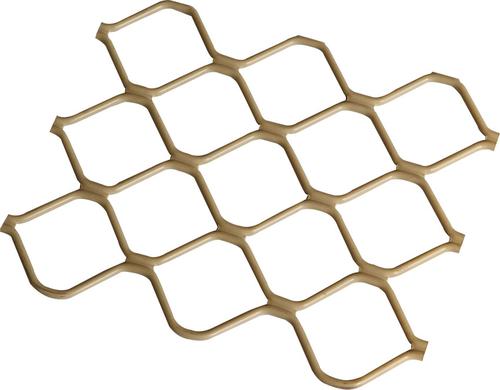

Aluminum Grill Aluminum

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ALUMINUM GRILL

Industrial aluminium profile

1)Material : 6063 6061 6060 and different aluminium alloy

2)Status:T4 T5 T6 or other special status

3)Surface treatment: mill finish, anodized sliver ,anodized bronze, anodized champagne, anodized black pearl, various power coating color, electrostatic sliver, electrostatic champagne, electrostatic golden, electrostatic titanium , machine polish sliver, machine polish bronze, wooden grain color, and Fluorocarbon spraying.

4)Annual capacity : 120000TON

5)Quality : China Nation Standard GB/T 5237 2008 (advanced class)

6)Use: can be widely using aluminium window, door, curtain wall, hand railing , normal aluminium profile, decorative and industrial aluminium profile

7)Advantage: Famous Brand reasonable&market price, soonest delivery and good after sale- service

8)Type of package:protection foam+heat contracted plastic film. / wooden packing / Metal pallet or depand on clientspecial requirement.

9)Payment term:T/T:30% of total value as deposite should paid by T/T within 3 days when confirmation ,and the remaining sum should be paid by T/T before delivery.L/C: 100% at sight

10)Delivery Day: 15-30days

11)Honor : CHINA FAMOUS TRADEMARK, CHINA TOP BRAND, ISO9001-2000, CHINA SQUARE&ROUND COMMITTEE DNV

- Q: What are the health advantages of utilizing products made from recycled aluminum?

- <p>Using recycled aluminum products can have indirect health benefits. By reducing the need for mining and refining new aluminum, it can decrease the environmental impact and exposure to hazardous substances associated with these processes. Additionally, recycling reduces waste in landfills, which can contribute to a cleaner environment and potentially lower the risk of health issues related to pollution. While the use of recycled aluminum products themselves doesn't directly impact health, the environmental benefits can create a healthier living space for everyone.</p>

- Q: does anybody have a great dry rub recipe for pork spareribs?

- If you are not coming close then there must be an error either in the way the measurement was made or your calculationMy calculation based on your numbers is a volume of 23.4 cm^3It appears that something in your measurement is not right, and it's not just typical measurement error.

- Q: The formula for calculating the length of aluminum rods for aluminum alloy production line

- Extrusion = (actual length / upsetting coefficient excess pressure) * extrusion coefficientExtrusion factor = extrusion barrel area / finished cross section areaMaterial length = number of nodes x fixed lengthEnd = extrusion lengthBar length = ((number of nodes x fixed length + cut end) / extrusion coefficient + residual pressure) * upsetting coefficient

- Q: Are the aluminum sheets available in different finishes (e.g., brushed, polished)?

- Aluminum sheets can be obtained in various finishes, such as brushed or polished, providing different surface textures and appearances. These finishes are achieved by employing diverse processes that modify the aluminum sheets. Brushed finishes, for instance, create a textured pattern by delicately brushing the surface with fine abrasive materials, resulting in a satin-like look. Conversely, polished finishes involve utilizing abrasive compounds or polishing wheels to buff the surface to a high shine. Consequently, these distinct finishes enable the customization and versatile utilization of aluminum sheets across different industries.

- Q: Wanting to buy a paintball gun that is good and perferably a package with a good gun but doesnt matter i am bored right now lol what bout u guys? but ya help with the paintball gun thanks D

- wash your hair and while its wet braid it down and spray setting lotion nit wait till it drys and take the braids out it will be very curlyi am a stylist thats how i curl my hair with out heat

- Q: hi, so i want to bake some chicken, unfortunately i don't have any aluminum foil right now, and the supermarket is far away from my house, so I was wondering, I have a recipient which is oven safe, however, my concern is, will my chicken be ruined or something, if I bake the chicken with no aluminum foil at all? thank you for your time.

- 1 He painted the Mona Lisa 2 He painted the last dining meal (idk rubbish english xd) 3 he designed flying mashines 4he designed war mashines 5he was also an architect

- Q: Milk and cereal i was watching the videos online and none of the people in it were fat.so im going to go on a cereal only diet

- because they don`t fry your hair ;; but after awhile you do need to buy a new ceramic curlin iron or straiqthenin iron because just like any other iron they do qet worn out if you don`t replace them eventually they can pose amaqe sometimes even more damaqe then usin a cheap onei`d spend the extra money qet a ceramic straiqhtener ;;

- Q: How to leak the foil seal?

- Also as a foil, aluminum foil, in Hongkong, also known as tin foil, is machined by aluminum foil mill into a sheet thickness below 0.2mm, mainly used for kitchen cooking, containing food or used to make some simple cleaning materials.

- Q: I live in Costa Rica and they are not easily (if at all) available hereHave tried searching the net to no avail.

- I usually tap a taper pin/punch of suitable diameter into the hole just tight enough for a snug fit, then I can clamp my visegrips onto it and twist it out without having to worry about crushing itThis usually works, but, every once in a while you'll get a real stubborn oneI just installed a big bore kit in a friends 2003 Triumph Bonneville and to get the one out of the cylinder I had to thread the inside, I left the tap in the hole, clamped the end of the tap in my bench vise, and then hit the cylinder with a soft mallet till the dowel pulled out.

- Q: ok im in 7th grade and i'm doing a science project it's a very very simple one its which design of boats made out of aluminum foil hold the most penniesAnd i've done everything except the back round information and i have no idea what that should be onPlease don't tell me what back round information is just tell me what i should Research to find out what the back round information is.

- Farming principally as the soils are very fertileAn exampleOn the Island of Java, Indonesia, there are many volcanoes both active and dormant and the soils there are very fertileFarmers are able to grow two crops of rice a year whereas in other places it is only one.

Send your message to us

Aluminum Grill Aluminum

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords