High Quality Aluminum Sheets for Sale in Houston - Alloy Aluminum Plate with Orange Peel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

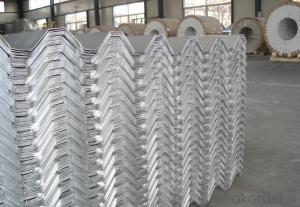

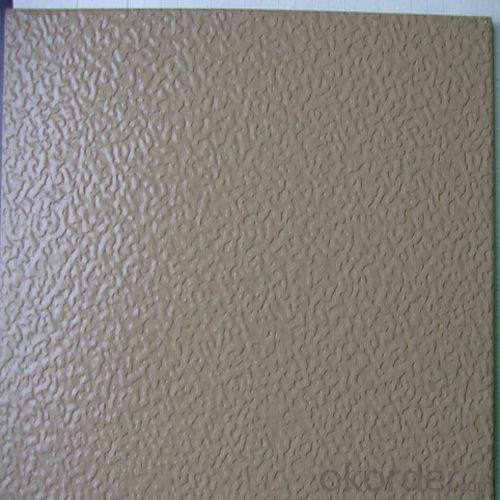

1.Structure of Alloy Aluminium Plate with Orange Peel Description:

Alloy Aluminium Plate with Orange Peel are widely used for building use, decoration use, making cookware, busing making, shipping building, airplane making and so on。Sizes of aluminum sheet for decoration use: Thickness: 0.3mm~300mm Width: Under 2000mm ( Standard: 1000mm, 1219mm, 1500mm, 1540mm) Length: Under 10000mm. Products commonly used in signs, billboards, building exterior decoration, bus body, high factory wall decoration, kitchen sink, lamp, fan, electronic components, chemical apparatus, sheet processing, deep drawing or spinning hollow ware, welding parts, heat exchangers, Bell surface and plate, plates, kitchen utensils, accessories, safety equipment and other.

2.Main Features of Alloy Aluminium Plate with Orange Peel:

1)Light

2)Corrosion-resistant

3) The mechanical intensity is high

4) The conducting rate is high

5)The reflecting rate is high.

3. Alloy Aluminium Plate with Orange Peel Images:

4. Alloy Aluminium Plate with Orange Peel Specification:

| Aluminium sheet | |||||

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| A1050,A1060, A1070,A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

| 3A21,A3003,A3105,A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

| A5052 ,A5005,A5083,A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

| A6061,A6082,A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

| A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: This question asks about the impact of aluminum sheets on the quality of air inside a building.

- <p>Aluminum sheets themselves do not directly affect indoor air quality in a building. They are inert materials that do not emit harmful gases or particles. However, the installation process may involve adhesives or sealants that could release volatile organic compounds (VOCs) temporarily, which can affect air quality. Proper ventilation during installation and after can mitigate this. Additionally, aluminum sheets can contribute to better air quality by providing a barrier against moisture and mold growth, which can be a concern with other building materials.</p>

- Q: What are the advantages of using aluminum sheets in the packaging industry?

- There are several advantages of using aluminum sheets in the packaging industry. Firstly, aluminum is a lightweight material, which makes it easier to handle and transport. Secondly, aluminum is highly resistant to corrosion, ensuring the protection of the packaged products. Additionally, aluminum has excellent barrier properties, providing a strong barrier against light, moisture, and oxygen, thus extending the shelf life of the packaged goods. Moreover, aluminum is malleable, allowing for easy shaping and customization of packaging designs. Lastly, aluminum is recyclable, making it a sustainable choice for the packaging industry and contributing to environmental conservation efforts.

- Q: What are the standard tolerances for aluminum sheets?

- The tolerances for aluminum sheets differ based on the specific industry and application. However, there are commonly accepted tolerances for aluminum sheets, such as thickness tolerances, flatness tolerances, and width and length tolerances. Thickness tolerances pertain to the allowable variation in the thickness of an aluminum sheet. The range of these tolerances depends on the grade and thickness of the sheet, and can be from +/- 0.005 inches to +/- 0.010 inches. Flatness tolerances specify the acceptable degree of flatness or deviation from a perfectly flat surface for an aluminum sheet. The range of flatness tolerances varies according to the application's specific requirements, and can be from a few thousandths of an inch to a few hundredths of an inch. Width and length tolerances define the allowable variation in the dimensions of an aluminum sheet. These tolerances can be expressed as +/- inches or as a percentage of the sheet's width or length. Generally, width and length tolerances for aluminum sheets fall within the range of +/- 0.25 to +/- 0.50 inches. It is important to note that these standard tolerances are subject to change and may differ depending on the specific industry, customer requirements, and the manufacturer's capabilities. Therefore, it is advisable to consult the manufacturer or industry-specific standards to determine the exact tolerances for aluminum sheets in a particular application.

- Q: Can aluminum sheets be used for food packaging?

- Yes, aluminum sheets can be used for food packaging. Aluminum is a safe and widely used material in the food industry due to its excellent barrier properties, resistance to moisture, and ability to maintain product freshness.

- Q: The diameter of a hole drilled through aluminum at 22°C is 7.50 mm. Find the diameter and the area of the hole at 89°C.

- If i was once you, i might depart a small 1cm gap on the high and cover it with mesh - these round ones don't appear to allow a lot air flow in any respect in my viv and i have three... I have a tendency to simply leave the glass open a bit of at both aspect. You'll have got to use a great mesh although to stop bugs escaping via it. BTW - i think you will have to make it slightly deeper... 1.5 at least in case you are maintaining reps a good way to grow to 12inch plus.

- Q: Can aluminum sheet be used for roofing?

- Yes, aluminum sheet can be used for roofing. Aluminum is a popular choice for roofing due to its numerous advantages. Firstly, aluminum is lightweight, making it easier to install and reducing the load on the structure of the building. Secondly, aluminum is highly durable and resistant to corrosion, which means it can withstand harsh weather conditions, such as heavy rain, snow, and UV radiation. Additionally, aluminum is non-combustible, making it a safe choice for roofing. Furthermore, aluminum is an environmentally friendly material as it is 100% recyclable, reducing its impact on the environment. Overall, aluminum sheet is a reliable and efficient option for roofing applications.

- Q: How does the surface roughness of aluminum sheet affect its performance?

- The overall performance of an aluminum sheet can be greatly influenced by its surface roughness. The roughness of the sheet's surface refers to the presence of irregularities, bumps, and texture. Various methods, such as Ra or Rz, can be used to measure these irregularities. One important effect of surface roughness on aluminum sheet performance lies in its ability to bond with other materials. A smoother surface allows for better adhesion, whether through welding, gluing, or painting. In contrast, a rough surface reduces the contact area and weakens the bond. This is particularly crucial in applications where the aluminum sheet is used structurally or in manufacturing processes that require strong adhesion. Surface roughness also affects the sheet's light reflection capabilities. A smoother surface reflects light more uniformly, resulting in a higher level of reflectivity. On the other hand, a rough surface scatters light in different directions, decreasing overall reflectivity. This property is relevant in applications like architectural cladding, where the desired aesthetic appearance depends on consistent light reflection. Additionally, the surface roughness of aluminum sheets can impact their resistance to corrosion. A smoother surface is less susceptible to corrosion as it provides fewer sites for corrosion to start. Conversely, a rougher surface may contain micro crevices or grooves that can trap moisture, salts, or other corrosive substances, speeding up the corrosion process. Maintaining a smooth surface is crucial in applications where corrosion resistance is vital, such as marine environments or outdoor structures. Lastly, surface roughness affects the mechanical properties of the sheet. A rough surface can concentrate stress, making the sheet more prone to fatigue, cracks, or other mechanical failures. Smoother surfaces distribute stress more evenly, enhancing the sheet's overall strength and resistance to deformation. In conclusion, the surface roughness of an aluminum sheet is of utmost importance in determining its performance. It affects adhesion, reflectivity, corrosion resistance, and mechanical properties. Therefore, it is essential to consider and control surface roughness in various applications to ensure optimal performance and longevity of aluminum sheets.

- Q: For example, in hydrangeas, when aluminum reacts with the anthocyanins in the flower's petals, the hydrangeas turn blue, but what chemical reaction occurs?

- Two factors affect the color in Hydrangea macrophylla cultivars: soil acidity and the presence of aluminium in the soil. To obtain a blue hydrangea, aluminum must be present in the soil. The pH of the soil should be low (4 - 4.5). In alkaline soil aluminium is tied up. The plants are unable to absorb the existing aluminium and the flowers will not bloom blue. Also, when aluminium in the soil is used up the flower color will be red or pink again. If the soil is watered with aluminium salts aluminium is accumulated in the petals and the color turns blue. Only red and pink colored Hortensis are suitable for the breeding of blue flowers. They contain the dye component delphinidin. At the end of this site you find explanation and the formula: www.uni-regensburg.de/Fakultaeten...

- Q: Are aluminum sheets suitable for use in cryogenic environments?

- Yes, aluminum sheets are suitable for use in cryogenic environments. Aluminum has excellent thermal conductivity, low density, and good mechanical properties at low temperatures, making it an ideal choice for applications in cryogenic environments. Additionally, aluminum has a low coefficient of thermal expansion, which allows it to maintain its structural integrity even under extreme temperature fluctuations.

- Q: What is a composite aluminum plate?

- The aluminum plastic composite plate is a composite material made of chemically treated coated aluminium plate as surface material, polyethylene plastic as core material, and manufactured on special aluminum plate production equipment.The unique properties of aluminum-plastic composite board itself has decided, its wide application: it can be used for building exterior wall, curtain wall, old building renovation, interior walls and ceiling decoration, advertising signs, display rack, dust purification engineering. The utility model belongs to a new type of building decoration material.APCP (also called APCP) as a new type of decorative materials, since the last century at the end of 80s early 90s from South Korea to China, with its economy, optional color diversity, convenient construction method, excellent processing performance, excellent fire resistance and noble quality, quickly favored by people.

Send your message to us

High Quality Aluminum Sheets for Sale in Houston - Alloy Aluminum Plate with Orange Peel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords