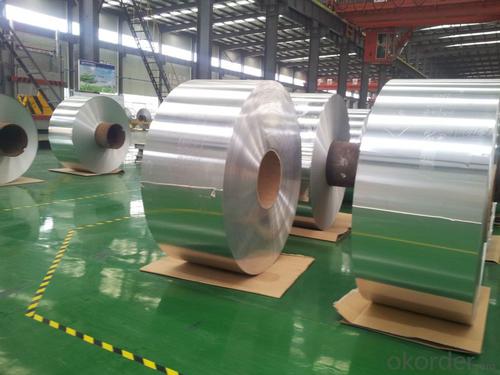

026 Aluminum Coil - 6083 T5 Aluminum Alloy Plate/Coil from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 90000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications

low price with high quality

free sample

efficiently and professionally delivery

good service

aluminum coil 1050 1060 1070 1100 1235 | | |||

Alloy | Thickness(mm) | Width(mm) | Temper | DC or CC |

0.2-4.0 | 20-1500 | O,H12,H22,H14,H24,H16,H26,H18 | DC, CC | |

4.0-12.0 | 1000-1900 | H111,H112 | DC | |

ID | 505mm,75mm,150mm etc. | |||

Packing | eye to wall | | ||

eye to sky | | |||

Application | Mainly in printing(PS plate base), Aluminum-plastic composite panel base, construction, decoration, capacitor, cover material, deep drawing products, refrigeration, air conditioner, automobile etc. | |||

6000 series aluminium alloy plate, generally called Al-Mg-Si alloy, the magnesium and silicon are used as main alloy element. Feature: most the advantages of 4000 series & 5000 series alloy, good corrosion resistant performance, well welding property, good oxidability, easy to spray-finishing,well oxidation coloring, good machinability, middle strength, often used used after heat treatments.

- Q: Guangdong where there are professional to do around the paper corner, is packing steel coil, aluminium coil that protect the edge of the both ends of the cylinder. Just the kind of picture.

- Guangdong Province, professional Foshan recommended edgeboard around Foshan Ansheng packaging. They are very professional in their circle, L shaped, and curved corners.

- Q: Aluminum coil Kaiping is out of arc plate, what's the matter?

- Aluminum coil Kaiping need to use "stretch bending straightening machine" to do leveling, before they can be leveled

- Q: Are aluminum coils suitable for architectural cladding?

- Yes, aluminum coils are suitable for architectural cladding. Aluminum is a lightweight and durable material that offers excellent corrosion resistance, making it ideal for exterior applications such as cladding. Additionally, aluminum coils can be easily formed and fabricated into various shapes and sizes, providing designers with flexibility in creating unique architectural designs.

- Q: Are there any limitations on the bending or shaping of aluminum coils?

- Yes, there are limitations on the bending or shaping of aluminum coils. Aluminum has a certain level of elasticity and ductility, which allows it to be bent or shaped to a certain extent. However, excessive bending or shaping can lead to cracking, deformation, or even breakage of the aluminum coils. Additionally, the thickness and temper of the aluminum coils can also affect their ability to be bent or shaped. Therefore, it is important to consider these limitations when working with aluminum coils to ensure their structural integrity is maintained.

- Q: How are aluminum coils used in the production of air ducts?

- Aluminum coils are commonly used in the production of air ducts as they offer superior heat transfer and corrosion resistance properties. These coils are typically formed into a specific shape and size, allowing for efficient airflow and distribution of air throughout the duct system. The aluminum material is lightweight, making it easier to handle during installation, and its durability ensures a long lifespan for the air ducts. Additionally, the coils can be easily customized to meet specific requirements, such as insulation or noise reduction. Overall, aluminum coils play a crucial role in the manufacturing of air ducts, contributing to their functionality, efficiency, and longevity.

- Q: What is the maximum coil diameter for aluminum coils?

- The maximum coil diameter for aluminum coils can vary depending on the specific application and manufacturing process. However, in general, the maximum coil diameter for aluminum coils typically ranges from 60 inches (152.4 cm) to 120 inches (304.8 cm). This diameter limit is determined by factors such as the size of the production equipment, the thickness and width of the aluminum sheet being processed, and the handling capabilities of the facility. It is important to consult with the manufacturer or supplier to determine the specific maximum coil diameter for a particular aluminum coil product.

- Q: What are the common joining techniques used for aluminum coils?

- The common joining techniques used for aluminum coils include welding, soldering, and adhesive bonding.

- Q: This question asks for criteria or methods to determine if an aluminum coil is of high quality.

- <p>To identify a good quality aluminum coil, consider the following factors: purity indicated by the alloy number, surface finish which should be smooth and free from defects, thickness consistency, and mechanical properties such as tensile strength and elongation. Check for certifications or quality standards compliance. Look for uniform color and absence of oil stains or rust. The coil should have precise dimensions and be free from dents or scratches. Additionally, consider the supplier's reputation and customer reviews.</p>

- Q: What are the different coil lengths available for aluminum coils?

- The different coil lengths available for aluminum coils can vary depending on the specific manufacturer and application. However, common coil lengths for aluminum coils range from 50 feet to 1000 feet or more.

- Q: Can aluminum coils be used in the manufacturing of medical devices?

- Yes, aluminum coils can be used in the manufacturing of medical devices. Aluminum is a versatile material that offers several advantages for medical device manufacturing. It is lightweight, corrosion-resistant, and has good thermal conductivity. These properties make aluminum coils suitable for various medical applications such as medical imaging equipment, surgical instruments, and prosthetics. Medical imaging devices, such as MRI and CT scanners, often use aluminum coils to transmit and receive electromagnetic signals. Aluminum's electrical conductivity allows for efficient signal transmission, enhancing the accuracy and quality of medical imaging. Additionally, aluminum's lightweight nature makes it easier to handle and maneuver during medical procedures. Aluminum coils are also used in the manufacturing of surgical instruments. These instruments require materials that are sterilizable, durable, and have high strength. Aluminum meets these requirements, as it can be easily sterilized using various methods, including steam, ethylene oxide, or gamma irradiation. Its durability ensures that the instruments can withstand repeated sterilization cycles without degradation, and its high strength ensures the instruments can withstand the forces applied during surgical procedures. Moreover, aluminum can be employed in the production of prosthetics, such as artificial limbs. Aluminum's lightweight nature makes it an ideal material for creating prosthetic devices that are comfortable for patients to wear and move around with. Additionally, its corrosion-resistant properties make it suitable for long-term use, as it can withstand exposure to body fluids and environmental factors. Overall, aluminum coils can indeed be used in the manufacturing of medical devices. Their lightweight, corrosion-resistant, and electrically conductive properties make them a valuable material for medical applications, contributing to the development of advanced and reliable medical devices.

Send your message to us

026 Aluminum Coil - 6083 T5 Aluminum Alloy Plate/Coil from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 90000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords