Aluminum Siding Strips - AL+PET+LDPE Insulation and EPE Foam Foil Mylar Film for Heat Seal

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Features high peel adhesion with good tack, temperature and aging resistance, and water vapor resistance

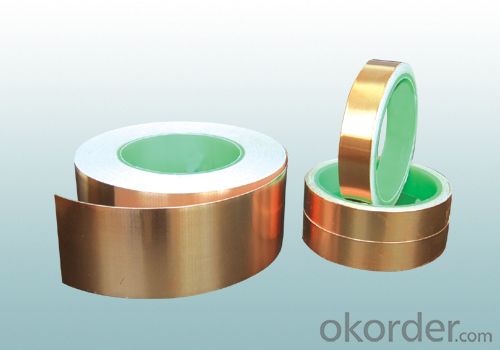

Aluminum Foil Tape Features:

1) High tensile strength aluminum foil made from special aluminum

alloy, coated with aggressive solvent-based acrylic adhesive,

which provides high peel adhesion and quick sticking

2) Designed for sealing joints and seams of foil jacketing in

air-conditioning duct work

Specifications:

1) Foil thickness: 18, 22, 26μ

2) Roll width: 48, 50, 60, 72, 75, 96, 100mm

3) Roll length: 27, 30, 45, 50m

4) Log roll: 1.2 x 45m, 1.2 x 50m

5) Jumbo roll: 1.2 x 1200m, 1.2 x 1000m

Inner packing:

Cut roll: printed core and shrink wrapping

Log roll: cardboard wrapping

Jumbo roll: plastic film + corrugated board wrapping

Outer packing:

Cut roll: carton

Log roll: carton + pallet / wooden case

Jumbo roll: wooden case

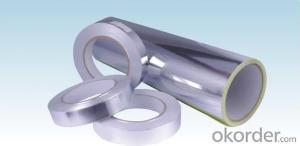

Aluminum Foil Mylar can be used to shield and isolate interference of electromagnetic waves and radio waves, etc

The Al-PET foil we made of aluminum foil and PET or colorized PET by scientifically processing. The width is between 5mm-1000mm; and the thickness is more than 0.025mm. They are used in electromagnetic shielding and electrical cables and wires shielding fields, etc.

Index of Al-PET foil:

Sequence No. | Index Character | Unit | Index |

1 | Thickness | mm | 0.025±0.00025 |

2 | Aluminum thickness | mm | 0.01±0.001 |

3 | PET thickness | mm | 0.012 ± 0.02 |

4 | Tensile strength | N/mm2 | ≥ 100 |

5 | Ultimate elongation | % | ≥ 20 |

6 | Bond strength | N/25mm | ≥ 8.0 |

7 | Aging resistance | Be immersed in 70±2°C water for 7days | Non-delaminating |

8 | Oxidative stability | - | excellent |

- Q: This question asks for a comparison between two types of siding materials: aluminum and steel. It seeks to understand the distinct characteristics that set these two materials apart.

- <p>Aluminum and steel siding are both popular choices for exterior cladding, but they have several differences. Aluminum is lightweight, corrosion-resistant, and requires minimal maintenance, making it ideal for coastal areas. It also comes in a variety of colors and finishes. Steel siding, on the other hand, is more durable and can withstand harsh weather conditions. It is heavier and stronger than aluminum, but it may require more maintenance, such as painting or coating to prevent rust. Steel is also more energy-efficient due to its insulating properties. Both materials offer different benefits and are suitable for different applications based on the climate, design preferences, and budget.</p>

- Q: Describe the steps involved in the production of aluminum strips from raw materials to the final product.

- <p>The process of manufacturing aluminum strips involves several key steps. Initially, raw materials, typically bauxite ore, are mined and then processed to extract alumina (aluminum oxide). This alumina is then dissolved in a cryolite bath at high temperatures within a reduction cell in the Hall-H茅roult process. Here, aluminum is reduced and collected as molten metal. The molten aluminum is then cast into ingots or directly into billets. These billets are then hot or cold rolled into strips, with multiple passes through rollers to achieve the desired thickness and width. The strips may undergo annealing to restore ductility and improve workability. Finally, the aluminum strips are cleaned, coated if necessary, and then cut to length, inspected, and packaged for distribution.</p>

- Q: What are the unique production techniques employed in the manufacturing of high-quality aluminum strips?

- <p>High-quality aluminum strips are produced using specialized manufacturing methods to ensure precision and consistency. Key methods include precision casting to achieve uniform thickness, continuous casting for improved material properties, and cold rolling to refine the strip's dimensions and surface finish. Annealing processes are also crucial for enhancing ductility and reducing hardness. Additionally, advanced surface treatments like anodizing or coating may be applied to improve corrosion resistance and aesthetics. Quality control measures such as strict dimensional checks and surface inspections are integral to ensuring the strips meet stringent quality standards.</p>

- Q: How much is the small aluminum belt excavator?

- There are many types of small tracked vehicles, but I don't know which one you want.

- Q: Is it possible to use aluminum strips as a material for fencing?

- <p>Yes, you can use aluminum strips for fencing. Aluminum is a popular choice due to its durability, resistance to corrosion, and low maintenance requirements. It is lightweight, easy to install, and can be shaped into various designs. Aluminum fencing is also known for its strength and can be an effective barrier for security purposes. However, it may not be suitable for all environments, especially where high wind loads or heavy impacts are expected, as it can dent or bend more easily than some other materials.</p>

- Q: How does the excavator aluminum belt turn in place?

- When the mechanical steering, separate driving force on the side of the track of unilateral, separation power can not overcome the ground friction due to the relative motion in a static state; and the other side of the track with power in motion, its trajectory is a circle, this is equivalent to us so we use your compasses to draw a circle; see mechanical steering.

- Q: What are the various classifications of aluminum strip based on their properties and applications?

- <p>Aluminum strips are classified into different grades based on their alloy composition, mechanical properties, and applications. Common grades include 1000 series (99% pure aluminum), 3000 series (aluminum-manganese alloys), 5000 series (aluminum-magnesium alloys), and 6000 series (aluminum-magnesium-silicium alloys). Each grade has specific characteristics, such as corrosion resistance, formability, and strength, making them suitable for various industries like construction, automotive, and packaging.</p>

- Q: What are the safety standards or guidelines that should be followed when using aluminum strips?

- <p>Yes, there are safety standards for using aluminum strips. These include ensuring that the aluminum is of the correct grade for its intended use, following guidelines for handling and storage to prevent contamination or damage, and adhering to regulations regarding worker safety, such as wearing appropriate personal protective equipment. Additionally, it's important to comply with local and international standards like ASTM or ISO specifications for aluminum products. Proper ventilation should be maintained during processing to avoid inhalation of dust or fumes, and safety measures should be taken to prevent fires, as aluminum can be a fire hazard in certain conditions.</p>

- Q: What kind of aluminum strip is most suitable for use in flooring applications?

- <p>The best type of aluminum strip for flooring is typically one that is durable, slip-resistant, and resistant to corrosion. Anodized aluminum strips are often preferred due to their strength, wear resistance, and ability to withstand heavy foot traffic. They also offer a sleek, modern aesthetic and can be used in various flooring applications, including commercial and residential settings. The thickness and width of the strip can vary depending on the specific requirements of the project, but a common choice is a 1mm to 3mm thick strip for stability and support.</p>

- Q: What is the minimum thickness that can be achieved when manufacturing an aluminum strip?

- <p>There is no absolute limit to how thin an aluminum strip can be made, but the practical limit is determined by the manufacturing process and the intended use of the strip. Modern technology allows for the production of aluminum strips as thin as a few micrometers. However, the thinness is constrained by factors such as material strength, ductility, and the specific application requirements. For instance, in the electronics industry, very thin aluminum strips are used for conductors, while in other applications, thicker strips might be necessary for structural integrity. The thinnest aluminum strips are often produced using techniques like rolling or extrusion, with the final thickness depending on the precision of these processes.</p>

Send your message to us

Aluminum Siding Strips - AL+PET+LDPE Insulation and EPE Foam Foil Mylar Film for Heat Seal

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords