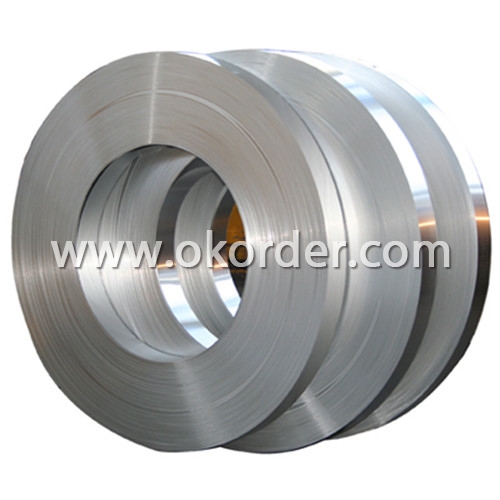

Thin Flat Aluminum Strips AA8006

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specifications of Aluminum Strips AA8006

Alloy Number | AA8006 |

Temper | Temper H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

Thickness | 0.10-500mm |

Diameter | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

Special specification is available on customers' requirements.

2. Usage/Applications of Aluminum Strips AA8006

Aluminum strips are widely used for PS printed materials substrate, building decoration materials, stamping products, building mirror materials, nameplate, insulation materials, aluminum plastic composite material, capacitor strip, transformer strip, welding parts, heat exchanger, clock surface and disk, kitchen utensils, reflecting apparatus etc.

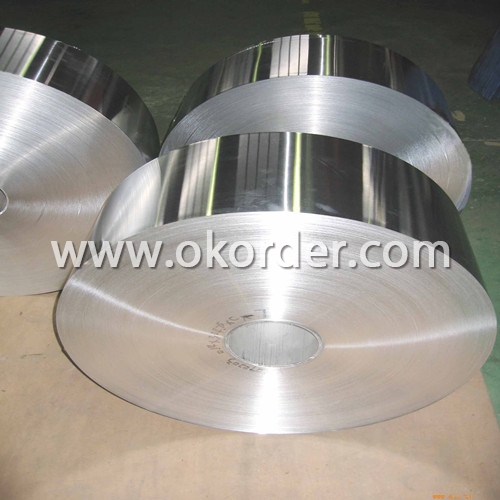

3. Packaging & Delivery of Aluminum Strips AA8006

Packaging: Seaworthy package, bubble plastic bag inside, anti-moisture paper wrapped outside, covered with cartons, on wooden pallets, in containers. Pallet weight: Max. 2.30 tons.

Shipment: the goods will be delivered in 30 days after getting the buyer's payment.

4. Production Flow of Aluminum Strips AA8006

Rolling--Annealing--Slitting—Sawing, Cut-To-Length, Shearing

- Q: What precautions should be taken into account when handling aluminum strips to ensure safety?

- <p>When using aluminum strips, safety concerns include avoiding skin contact with sharp edges to prevent cuts, ensuring proper ventilation to prevent inhalation of aluminum dust which can cause respiratory issues, and using protective eyewear to shield against flying debris. Additionally, it's crucial to handle aluminum strips carefully to prevent them from becoming projectiles, especially when cutting or bending. Always use appropriate tools designed for metal work and follow safety guidelines specific to the task at hand.</p>

- Q: This question asks about the various forms or configurations that aluminum strips can take in terms of their shape.

- <p>Aluminum strips are available in various shapes to meet different industrial and manufacturing needs. Common shapes include rectangular, square, and circular strips. Rectangular strips are the most common and can be found in various thicknesses and widths. Square strips are less common but still used in specific applications. Circular strips, also known as aluminum wire, are used in electrical applications and other areas requiring a round cross-section. Other shapes like triangular, hexagonal, or custom profiles can also be produced but are less standard and typically require specialized manufacturing processes.</p>

- Q: What is the best capacitance for an aluminum ribbon tweeter?

- You can go to your problem related professional website forum to see, there gathered a lot of professionals, you can solve the problem.

- Q: This question asks for the duration aluminum strips can last or their service life.

- <p>The lifespan of aluminum strips can vary significantly based on factors such as the environment in which they are used, the quality of the material, and the specific application. In general, if properly maintained and not exposed to harsh conditions, aluminum strips can last for several decades. For instance, in construction, aluminum strips used in framing can have a lifespan of 20 to 40 years. However, in more aggressive environments or with frequent wear and tear, this lifespan can be considerably shorter. It's important to note that aluminum is a recyclable material, and its lifespan can be extended through recycling processes.</p>

- Q: Explain how aluminum strips can impact the fuel efficiency of a vehicle.

- <p>Aluminum strips, when used in the context of vehicle fuel efficiency, typically refer to the use of aluminum in vehicle construction to reduce weight. Aluminum is a lightweight material with high strength, which can significantly decrease the overall weight of a vehicle. By reducing the weight, the engine doesn't have to work as hard to move the vehicle, leading to less fuel consumption. Additionally, lighter vehicles can accelerate and decelerate more quickly, which can also contribute to improved fuel efficiency. However, it's important to note that the impact on fuel efficiency can vary based on the vehicle's design, driving conditions, and other factors.</p>

- Q: What is the standard thickness for aluminum strip roofing materials?

- <p>The recommended thickness for aluminum strip roofing varies depending on the specific application and local building codes. Generally, aluminum strip roofing is available in thicknesses ranging from 0.018 to 0.032 inches (0.46 to 0.81 mm). For residential applications, a thickness of 0.024 to 0.028 inches (0.61 to 0.71 mm) is commonly used, while commercial buildings might require a thicker strip, around 0.032 inches (0.81 mm) for added durability and longevity. Always consult with a roofing professional or follow local building codes to determine the appropriate thickness for your specific project.</p>

- Q: This question asks about the various color options available for aluminum strips.

- <p>Aluminum strips are available in a variety of colors to suit different applications and aesthetic preferences. Common colors include silver, which is the natural color of aluminum, black, white, and clear anodized. Additionally, they can be coated or anodized in other colors such as gold, bronze, blue, red, and green. Custom colors are also possible with specialized coating or anodizing processes. The choice of color can depend on the specific use of the aluminum strip, such as for decorative purposes, architectural applications, or industrial uses where color coding is required.</p>

- Q: Can aluminum strips withstand harsh conditions like high humidity or salt spray?

- <p>Aluminum strips can be used in harsh environments to some extent, but their performance may be compromised. Aluminum is resistant to corrosion, making it suitable for high humidity conditions. However, in environments with significant salt spray exposure, aluminum can corrode over time, particularly due to the formation of galvanic cells when in contact with other metals. Protective coatings or anodizing can enhance its corrosion resistance, but it's not entirely impervious. Thus, while aluminum can be used in such environments, it requires proper protection and maintenance to ensure longevity.</p>

- Q: Is the use of aluminum strips considered to be eco-friendly?

- <p>Aluminum strips are generally considered environmentally friendly due to their recyclability and low energy consumption in production. Aluminum is one of the most recycled materials globally, which means it can be reused multiple times without significant loss of quality. Additionally, producing aluminum from recycled materials requires only 5% of the energy needed to produce new aluminum from raw materials. However, the initial production process of aluminum is energy-intensive, so the environmental impact can be significant if recycling rates are low. Overall, aluminum strips are environmentally friendly when recycled, but the sustainability of their production depends on the balance between new production and recycling.</p>

- Q: Is it possible to utilize recycled aluminum to fabricate new aluminum strips?

- <p>Yes, recycled aluminum can be used to make new aluminum strips. Recycling aluminum is an efficient process that conserves energy and resources. The recycled aluminum is melted down and then reformed into new shapes, including strips. This process is not only environmentally friendly but also cost-effective, as it requires less energy compared to producing aluminum from raw materials. The recycled aluminum strips maintain the same properties as those made from new aluminum, making them suitable for various applications.</p>

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 1996 |

| Annual Output Value | Above US$200 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Thin Flat Aluminum Strips AA8006

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords