1/4 Aluminum Strips Al+Pet+Ldpe Insulation and Epe Foam Foil Film for Heat Seal

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 40 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Features high peel adhesion with good tack, temperature and aging resistance, and water vapor resistance

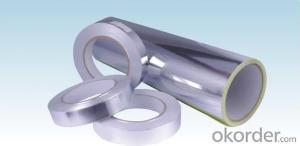

Aluminum Foil Tape Features:

1) High tensile strength aluminum foil made from special aluminum

alloy, coated with aggressive solvent-based acrylic adhesive,

which provides high peel adhesion and quick sticking

2) Designed for sealing joints and seams of foil jacketing in

air-conditioning duct work

Specifications:

1) Foil thickness: 18, 22, 26μ

2) Roll width: 48, 50, 60, 72, 75, 96, 100mm

3) Roll length: 27, 30, 45, 50m

4) Log roll: 1.2 x 45m, 1.2 x 50m

5) Jumbo roll: 1.2 x 1200m, 1.2 x 1000m

Inner packing:

Cut roll: printed core and shrink wrapping

Log roll: cardboard wrapping

Jumbo roll: plastic film + corrugated board wrapping

Outer packing:

Cut roll: carton

Log roll: carton + pallet / wooden case

Jumbo roll: wooden case

Aluminum Foil Mylar can be used to shield and isolate interference of electromagnetic waves and radio waves, etc

The Al-PET foil we made of aluminum foil and PET or colorized PET by scientifically processing. The width is between 5mm-1000mm; and the thickness is more than 0.025mm. They are used in electromagnetic shielding and electrical cables and wires shielding fields, etc.

Index of Al-PET foil:

| alu-pet | |||||||

| structure | Thickness | weight | Yield | ||||

| (gr/m2) | (m2/kg) | ||||||

| 1 | 21mic | 37 | 27.5 | ||||

| 2 | 24mic | 41 | 24 | ||||

| 3 | 23mic | 43 | 23 | ||||

| 4 | 26mic | 48 | 21 | ||||

| Roll,Sizes&Packing: | |||||||

| Standard core ID : 52mm or 76mm(cardboard or plastic core) | |||||||

| Minimum width : 8mm | |||||||

| Maximum width : 1000mm | |||||||

| Roll OD : 400mm(>20mm width) | |||||||

| 300mm(<20mm width) | |||||||

Sequence No. | Index Character | Unit | Index |

1 | Thickness | mm | 0.025±0.00025 |

2 | Aluminum thickness | mm | 0.01±0.001 |

3 | PET thickness | mm | 0.012 ± 0.02 |

4 | Tensile strength | N/mm2 | ≥ 100 |

5 | Ultimate elongation | % | ≥ 20 |

6 | Bond strength | N/25mm | ≥ 8.0 |

7 | Aging resistance | Be immersed in 70±2°C water for 7days | Non-delaminating |

8 | Oxidative stability | - | excellent |

- Q: Is it good to drive a wheeled excavator or an aluminum belt?

- How many people do you say you drive, or do you drive more tanks? However, the western development is over, the excavator is not fragrant. Go to the second-hand Internet to see the excavator is very cheap. Take mine. Thank you。。。

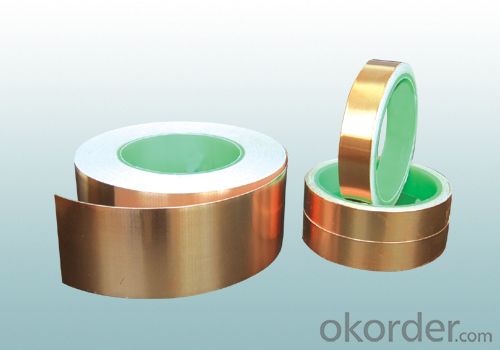

- Q: This question seeks to understand the distinctions between aluminum and copper as materials used for siding in construction.

- <p>Aluminum and copper siding differ in several ways. Aluminum is lightweight, corrosion-resistant, and requires minimal maintenance, making it a popular choice for durability and low cost. It is also available in a variety of colors and finishes. Copper, on the other hand, is heavier and more expensive, but it develops a natural patina over time, which can add a unique aesthetic appeal. Copper is also highly durable and recyclable, and it does not require painting. However, it is more prone to denting and can be more challenging to install. In terms of thermal performance, copper conducts heat better than aluminum, which can be an advantage in certain climates.</p>

- Q: Explain the role that aluminum strips play within the construction of a building.

- <p>Aluminum strips in a building serve multiple functions. They are often used for thermal insulation, helping to reduce heat transfer between the interior and exterior of the building, thereby improving energy efficiency. Aluminum strips also play a role in moisture control by preventing water infiltration, which can protect the building's structural integrity. Additionally, they can be used for aesthetic purposes, adding a modern and sleek appearance to the building's exterior. In some cases, aluminum strips are used in the construction of window and door frames, providing strength and durability while also offering good resistance to corrosion.</p>

- Q: This question asks for an explanation of the various types of aluminum cladding materials used in construction.

- <p>Aluminum cladding is a popular choice in construction for its durability and low maintenance. The different types include: 1. Aluminum Composite Material (ACM), which is lightweight and consists of two thin aluminum sheets with a non-aluminum core. 2. Aluminum Plate, a thicker and more rigid material used for structural applications. 3. Aluminum Extrusions, which are formed by pushing aluminum through a die to create specific shapes and profiles. 4. Aluminum Coil Coating, where aluminum coils are coated with a protective layer and used for roofing and siding. 5. Anodized Aluminum, which undergoes an electrochemical process to increase its resistance to wear and corrosion. Each type has specific applications and properties, making them suitable for different construction projects.</p>

- Q: What are the unique production techniques employed in the manufacturing of high-quality aluminum strips?

- <p>High-quality aluminum strips are produced using specialized manufacturing methods to ensure precision and consistency. Key methods include precision casting to achieve uniform thickness, continuous casting for improved material properties, and cold rolling to refine the strip's dimensions and surface finish. Annealing processes are also crucial for enhancing ductility and reducing hardness. Additionally, advanced surface treatments like anodizing or coating may be applied to improve corrosion resistance and aesthetics. Quality control measures such as strict dimensional checks and surface inspections are integral to ensuring the strips meet stringent quality standards.</p>

- Q: The question asks if it's possible to use various adhesives or fasteners for installing different kinds of aluminum strips.

- <p>Yes, you can use different types of adhesives or fasteners to install different types of aluminum strips. The choice depends on the application, the weight of the strip, and the surface it's being attached to. For lightweight strips and smooth surfaces, adhesives like double-sided tape or construction adhesive can be effective. For heavier strips or where a more permanent solution is needed, mechanical fasteners such as screws or rivets might be more appropriate. Always consider the strip's weight, the surface material, and the desired longevity of the installation when selecting the type of adhesive or fastener.</p>

- Q: Is it possible to manufacture high-quality aluminum strips exclusively from recycled materials?

- <p>Yes, high-quality aluminum strips can be made from recycled materials. The recycling process allows for the production of aluminum that is often indistinguishable from primary aluminum in terms of quality. Recycling aluminum is more energy-efficient and has a lower environmental impact compared to mining and refining new aluminum. The process involves melting the scrap aluminum, which can be sourced from various products, and then casting it into new forms, such as strips. This not only conserves resources but also reduces waste, making it a sustainable practice in the aluminum industry.</p>

- Q: What is the color of aluminum coating

- Advantages: uniform color, bright and clean, strong adhesion, strong and durable, acid and alkali resistance, corrosion resistance, weather resistance, decay resistance, friction resistance, UV resistance, weather resistance.

- Q: Which brand of aluminium band for dry transformer?

- Of course, according to the requirements of customers, but most of them are pure aluminum

- Q: This question asks if there are certain types of aluminum that have a lower environmental impact compared to others.

- <p>Yes, there are types of aluminum that are considered more environmentally friendly. Recycled aluminum, for instance, has a significantly lower environmental impact compared to newly mined aluminum. The production of recycled aluminum requires only 5% of the energy needed to produce new aluminum from raw materials. Additionally, aluminum alloys with lower carbon footprints, such as those with reduced heavy metal content, can be more eco-friendly. However, it's important to consider the entire lifecycle of aluminum, including extraction, production, use, and disposal, to determine its environmental friendliness.</p>

Send your message to us

1/4 Aluminum Strips Al+Pet+Ldpe Insulation and Epe Foam Foil Film for Heat Seal

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 40 m²

- Supply Capability:

- 50000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords