Aluminum Transition Strips for Flooring - 5052 5754 5083 6061 Metal Alloy Aluminum Sheet Manufactured in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

Corrosion resistance can be excellent due to a thin surface layer of aluminium oxide that forms when the metal is exposed to air, effectively preventing further oxidation. The strongest aluminium alloys are less corrosion resistant due to galvanic reactions with alloyed copper.This corrosion resistance is also often greatly reduced by aqueous salts, particularly in the presence of dissimilar metals.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

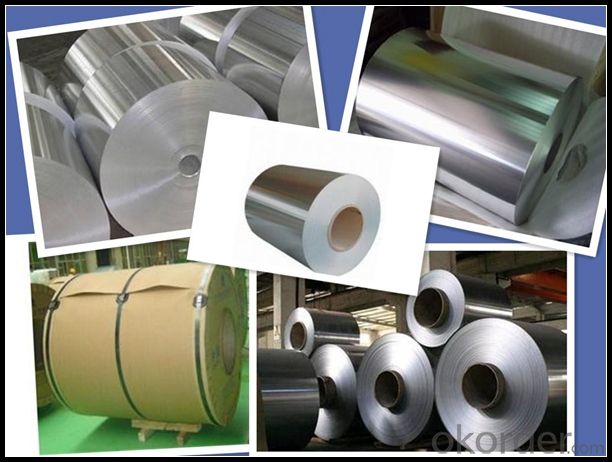

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: What benefits can be gained from incorporating aluminum strips in construction projects?

- <p>Aluminum strips offer several advantages in construction, including high strength-to-weight ratio, which means they are strong yet lightweight. They are also resistant to corrosion, making them suitable for outdoor applications and harsh environments. Aluminum strips are easy to work with, allowing for easy installation and customization. They are also energy-efficient, as they reflect heat and can help reduce cooling costs. Additionally, aluminum is recyclable, contributing to sustainability and reducing waste.</p>

- Q: Would you like to buy a sensor for measuring the thickness of aluminum ribbon?

- ZTMS08 system has been optimized through performance and field calibration, and its main technical specifications and performance parameters comply with the relevant regulations. It can be widely used for thickness measurement of paper, paperboard and other sheet materials.

- Q: What is the difference between cold rolling and hot rolling of aluminium plate and aluminium strip? Which kind of aluminum plate is good? Speak a little more popularly

- The aluminum plate and the aluminum band are better understood. One is the plate and the other is the coil.

- Q: Is it possible to use aluminum strips as materials for roofing membranes?

- <p>Yes, aluminum strips can be used for roofing membranes. They are known for their durability, corrosion resistance, and lightweight properties, making them suitable for various roofing applications. Aluminum strips can be used in the form of standing seam metal roofs, which are popular for their sleek appearance and strength. They are also low maintenance and can be recycled, contributing to their environmental sustainability. However, it's important to ensure proper installation and sealing to prevent leaks and maintain the integrity of the roof.</p>

- Q: This question asks for a comparison between aluminum strips and other roofing materials in terms of their characteristics and performance.

- <p>Aluminum strips are lightweight and highly durable, offering excellent resistance to corrosion and weathering. They are low-maintenance and have a long lifespan, often outlasting other materials like asphalt shingles. Compared to metal roofing, aluminum strips may be more prone to denting, but they are quieter and less likely to expand or contract with temperature changes. When compared to tile or slate, aluminum is much lighter, reducing the load on the structure and installation costs. However, it may not offer the same aesthetic appeal or insulation properties. Overall, aluminum strips are a cost-effective and eco-friendly choice for roofing, especially in areas with harsh weather conditions.</p>

- Q: Is it possible to utilize aluminum strips as a material for insulating interior walls?

- <p>Aluminum strips are not typically used for interior wall insulation. Insulation materials are designed to provide thermal resistance, and aluminum is a good conductor of heat, which makes it unsuitable for insulation purposes. Common insulation materials include fiberglass, mineral wool, and polyurethane foam, which are effective at reducing heat transfer. Aluminum strips might be used in construction for other purposes, such as reinforcement or as a vapor barrier, but not for insulation.</p>

- Q: This question asks for a comparison of the benefits and drawbacks of using aluminum strips as a roofing material.

- <p>Aluminum strips for roofing offer several advantages, including durability, resistance to corrosion and rust, and low maintenance requirements. They are lightweight, which reduces the load on the structure, and can be easily recycled. Additionally, aluminum strips can be coated with various finishes to match architectural styles, enhancing aesthetic appeal. However, they also have some disadvantages, such as being more expensive than traditional materials like asphalt shingles. They can also be noisy during rain and hail, and may require professional installation due to their specialized nature.</p>

- Q: Is it possible to use aluminum strips as a roofing material in regions with cold weather conditions?

- <p>Yes, aluminum strips can be used for roofing in cold climates. Aluminum is a durable and lightweight material that is resistant to corrosion and weathering, making it suitable for various climates, including cold ones. It doesn't rust and can withstand heavy snow loads. However, it's important to consider the thermal properties of aluminum, as it conducts heat and cold efficiently, which may necessitate additional insulation to maintain the desired indoor temperature. Additionally, proper installation and underlayment are crucial to prevent moisture and heat loss.</p>

- Q: Is it possible to use aluminum strips for the exterior walls of a building?

- <p>Yes, aluminum strips can be used for exterior walls. They are lightweight, durable, and resistant to corrosion, making them suitable for cladding and facades. Aluminum strips can also be coated with various finishes to enhance their appearance and protect against weathering. They are commonly used in modern architecture for both aesthetic and functional purposes, offering a sleek and contemporary look while providing insulation and weather protection.</p>

- Q: Describe the steps involved in the manufacturing process of aluminum strips.

- <p>The process for manufacturing aluminum strips involves several key steps. Initially, aluminum ingots are melted in a furnace, often using a direct current furnace for better control over the melting process. The molten aluminum is then poured into molds to create a cast billet. This billet is then heated and passed through a series of rolling mills to reduce its thickness and achieve the desired strip dimensions. During rolling, the aluminum is continuously cooled to control its temperature and maintain its mechanical properties. After rolling, the aluminum strip may undergo additional processes such as annealing to improve ductility or coating to provide a protective layer. Finally, the strip is cut to length, inspected for quality, and packaged for distribution.</p>

Send your message to us

Aluminum Transition Strips for Flooring - 5052 5754 5083 6061 Metal Alloy Aluminum Sheet Manufactured in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords